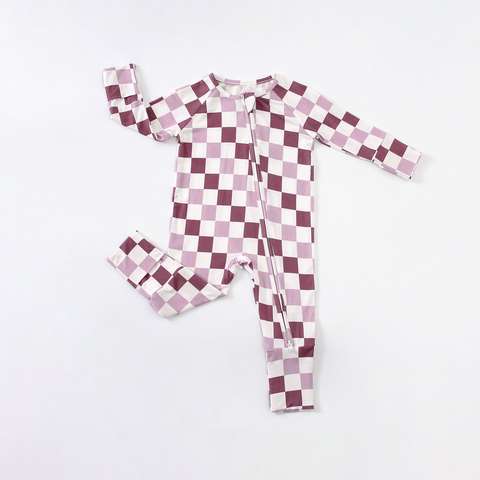

Astm F963 Bamboo Pajamas Mom And Baby Oekotex 100 Supplier

Bamboo Pajamas for Mom and Baby: An Industrial Perspective

Bamboo fabric has been gaining significant traction in the textile industry, particularly for its application in producing pajamas for moms and babies. Known for its eco-friendliness, softness, and breathability, bamboo-based textiles have become a sought-after material among manufacturers. This article delves into the technical aspects of bamboo fabric, emphasizing factors like GSM (grams per square meter), fabric density, and the machinery involved in producing high-quality bamboo pajamas for moms and babies.

Understanding the Importance of Fabric GSM and Density in Bamboo Pajamas

One of the key considerations in manufacturing bamboo pajamas is the GSM. This metric evaluates the fabric's weight per square meter and serves as an essential factor in determining the quality, durability, and comfort of the garment.

- Lightweight Fabric: Fabrics with a lower GSM, typically around 120-160 GSM, are often used for summer bamboo pajamas for moms and babies. This GSM range ensures breathable, lightweight, and soft pajamas that cater to warm weather.

- Midweight Fabric: Mid-range GSM of 180-220 is ideal for year-round pajamas. These fabrics strike a balance between softness and durability, offering a comfortable yet resilient choice for both moms and babies.

- Heavyweight Fabric: For cooler climates, heavier bamboo fabrics with 250+ GSM provide excellent thermal insulation while maintaining breathability.

Fabric density, on the other hand, is a measurement of how tightly the fibers are woven or knitted together. For bamboo garments, achieving the right density is crucial to maintaining their signature softness and stretch while ensuring longevity. Density impacts the fabric’s drape, strength, and its ability to stay intact after multiple industrial wash cycles, especially for baby clothing where durability and comfort are paramount.

The Role of Advanced Machinery in Bamboo Pajama Manufacturing

Industrial machinery plays a pivotal role in transforming raw bamboo fibers into luxurious, soft pajama fabric. Below are a few critical processes and machines employed in this production:

1. Bamboo Fiber Extraction Machines

The first step in creating bamboo pajamas involves converting bamboo plants into usable pulp. Mechanical or chemical processing separates bamboo fibers. An industrial-scale crushing or knife segment machine is a common tool in this stage, followed by steam explosion treatment to soften the bamboo’s lignin without using harsh chemicals.

2. Yarn Spinning Machines

Once bamboo pulp has been processed, it is spun into yarn. Open-end rotor spinning systems and ring-spinning machines are widely used in this process. Ring spinning, noted for its excellent control over fiber alignment, produces yarn with high tensile strength, which is crucial for apparel worn daily, such as mom and baby pajamas.

3. Knitting and Weaving Machines

The next stage involves either knitting or weaving the bamboo yarn into fabric. For bamboo pajamas, circular knitting machines are preferred because they create soft, stretchable fabrics well-suited for garments. The knitting process ensures the flexibility and comfort required for baby apparel that will come into direct contact with sensitive skin.

4. Dyeing and Finishing Machines

Dyeing bamboo fabric necessitates gentle yet high-quality processes to retain the garment's softness and vibrant colors. Advanced dyeing machines such as soft-flow dyeing machines are tailored for bamboo fabric dyeing, making them particularly suitable for mom-and-baby pajamas where fabric quality cannot be compromised.

Finishing machines add an additional step to make bamboo fabrics shrink-resistant and enhance their moisture-wicking properties. Heat-setting equipment is often used for this, ensuring the fabric maintains its shape and flatness post-dyeing and wear.

Technical Advantages of Bamboo Fabric in Mom and Baby Pajamas

When designing clothing for moms and babies, manufacturers often prioritize comfort, safety, and durability. Bamboo checks all the boxes, making it a premium material for this application.

- Hypoallergenic Properties: Bamboo fabric’s natural hypoallergenic characteristics make it ideal for baby clothing. The absence of harmful chemicals during production lessens the chance of skin irritations.

- Moisture-Wicking and Thermal Regulation: Bamboo fabric wicks moisture as efficiently as synthetic counterparts, making it suitable for all seasons. For infants prone to overheating, this property ensures a comfortable temperature.

- Sustainability: Bamboo grows rapidly and regenerates without pesticides or fertilizers, making it a sustainable choice. Responsible sourcing and processing further reduce environmental impacts.

- Durability and Stretch: Bamboo fabric, when produced with the right density and GSM, achieves an impressive balance of strength and elasticity, retaining softness even after industrial laundering cycles.

Optimizing Costs and Efficiency in Bamboo Pajama Production

In a competitive B2B market, maintaining operational efficiency is just as critical as fabric quality. Below are strategies to enhance cost-effectiveness without sacrificing quality:

1. Use of Energy-Efficient Machines

Switching to energy-efficient spinning, knitting, and dyeing machines can significantly reduce operational costs over time. For example, incorporating inverter-driven motors in processing machinery can lower energy consumption by up to 30%.

2. Bulk Material Sourcing

Sourcing bamboo fibers from vertically integrated suppliers often results in lower material costs. Additionally, establishing agreements for bulk purchase of industrial yarn spools ensures consistency in material quality.

3. Automation in Fabric Inspection

Modern fabric inspection systems with AI-based defect detection not only decrease labor costs but also minimize wastage. High-speed scanners can detect inconsistencies in thread density or GSM at early production stages, reducing rework costs.

Meeting Consumer Expectations in the Mom-and-Baby Market

The appeal of eco-conscious and baby-safe products is a critical driver in the success of bamboo pajamas. Partner businesses should consider the following requirements when entering this niche market:

| Fabric Type | Pima Cotton |

| Compliance | GOTS Organic |

| Customization | Bespoke |

| Lead Time | 20 Days |

- Certifications: Ensure products meet OEKO-TEX® Standard 100 or similar certifications, guaranteeing that fabrics are free from harmful substances.

- Customizability: Offer customization options for color, GSM, and finishing to cater to varied consumer preferences and climatic conditions.

- Allergy Testing: Provide third-party verification for hypoallergenic claims to build trust with end consumers.

: The Edge of Bamboo in Industrial Textile Production

The industrial production of bamboo pajamas for moms and babies is a technically nuanced process that prioritizes sustainability, efficiency, and quality. By optimizing key attributes such as GSM, fabric density, and the use of advanced machinery, manufacturers can ensure exceptional products that align with market demand. Partnering with reliable supply chains and investing in automation and energy-efficient technologies will further enhance production capabilities while reducing environmental impact. As the demand for eco-conscious products continues to grow, bamboo-based fabrics will remain a cornerstone of innovation in the textile industry.