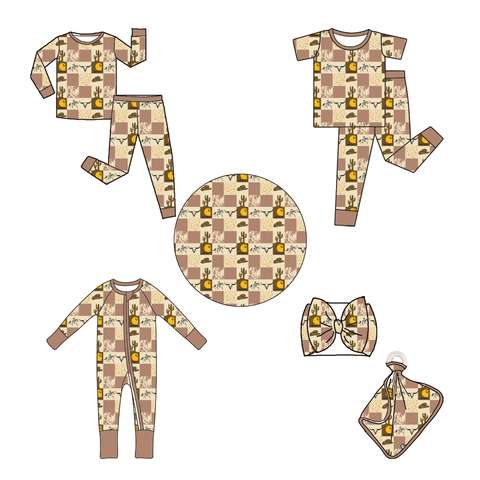

Bespoke Baby Zip Baby Onesie Newborn Suit Oekotex 100 Supplier

Baby Zip Baby Onesie Newborn Suit: Engineering Insights for Superior Comfort and Manufacturing Excellence

The Baby Zip Baby Onesie is a product that bridges the gap between comfort, durability, and manufacturing efficiency. For businesses involved in B2B apparel production and retail, understanding the technical aspects of fabric density, GSM (grams per square meter), and the industrial machinery used in its creation is critical. In this article, we take a technical dive into the engineering principles that drive the production of this essential newborn suit.

Understanding GSM: The Key to Fabric Performance

GSM, or grams per square meter, is a fundamental concept in fabric engineering. It offers a measurable way to characterize the weight and density of textiles. For the Baby Zip Baby Onesie, selecting the optimal GSM is critical to achieving the ideal balance of comfort, breathability, and durability.

For baby apparel, particularly onesies designed for newborns, a GSM range of 120 to 180 is most commonly desirable. Lightweight fabrics (around 120 GSM) ensure soft and breathable comfort, which is essential for a baby’s sensitive skin. Higher GSM ranges (closer to 180 GSM), on the other hand, add durability without compromising the softness, making the onesie more resistant to repeated washing and stretching.

The Baby Zip Baby Onesie leverages a GSM of approximately 150 to strike a perfect equilibrium. This weight provides sufficient thickness to keep newborns warm and secure while allowing enough airflow for temperature regulation. It also reduces the risk of irritation, as excessive weight or density in fabric may lead to discomfort or overheating.

Fabric Density and Material Selection

Alongside GSM, fabric density plays a vital role in determining the tactile and functional properties of a garment. While often confused with GSM, fabric density refers to the number of threads or fibers per unit area of fabric, typically measured per centimeter or inch. High fabric density enhances the material's durability and resistance to wear and tear, both of which are critical for baby clothes subjected to frequent use and washing.

For the Baby Zip Baby Onesie, cotton is the material of choice due to its hypoallergenic properties and moisture-wicking abilities, which ensure the baby's skin remains dry and irritation-free. High-quality combed cotton is commonly used to further increase softness while maintaining durability. For industrial applications, blending fabrics with a small percentage of spandex (typically around 5%) can introduce elasticity, enabling the fabric to retain shape and facilitate ease of movement for the baby.

The fabric density in the Baby Zip Baby Onesie is engineered with a focus on achieving a fine balance between stretchability and structural resilience. Industrial weaving or knitting plays a pivotal role here, as the tightness of the knit or weave can significantly impact the onesie's performance. Ribbed or interlock knit patterns are ideal for such baby clothes, offering enhanced strength and elasticity without adding to the garment's weight.

Industrial Machinery: Precision in Baby Onesie Production

The production of high-quality newborn onesies like the Baby Zip Baby Onesie relies heavily on advanced industrial machinery. From fabric weaving to garment assembly, cutting-edge automation ensures consistency, efficiency, and precision in manufacturing.

Fabric Knitting and Weaving Machines

Circular knitting machines are commonly employed for the production of seamless baby onesie fabrics. These machines ensure uniformity in knitting patterns, eliminating irregularities and improving fabric integrity. Advanced automated weaving machines are also used for tighter fibers to enhance fabric durability. The flexibility of these machines allows manufacturers to fine-tune fabric density and texture for optimal performance.

CNC Cutting Machines

Precision in fabric cutting is crucial for minimizing waste and ensuring production efficiency. CNC (Computer Numerical Control) cutting machines are extensively used in the garment industry to execute highly accurate cuts based on digital patterns. These machines allow manufacturers of the Baby Zip Baby Onesie to maintain consistent sizing and reduce fabric waste, leading to cost efficiency and environmental benefits.

Overlock and Flatlock Sewing Machines

To handle the construction of baby onesies, overlock sewing machines are essential. These machines efficiently prevent fraying by locking the edges of the fabric together during assembly. The Baby Zip Baby Onesie, in particular, benefits from flatlock machines, which deliver seamless finishes that prevent irritation against sensitive baby skin. The use of such machinery ensures the garment’s construction is robust and suitable for repeated use.

Automated Zipper Installation

A defining feature of the Baby Zip Baby Onesie is its integrated zip, which enhances functionality and ease of use for parents. Automated zipper installation machinery ensures precise alignment and secure attachment of the zipper to the garment. This technology not only accelerates production but also enhances the product’s durability, as improper installation of zippers can result in higher failure rates over time.

Quality Assurance in Baby Clothing Production

In addition to material selection and the use of advanced machinery, strict quality control measures are vital in ensuring the final product meets the required standards. For newborn clothing, regulations and industry standards mandate compliance with safety, chemical, and performance guidelines.

For instance, third-party certifications such as OEKO-TEX® Standard 100 are frequently sought by manufacturers to guarantee that the materials used are free from harmful chemicals and safe for baby use. Automated testing equipment is also employed to assess fabric strength, elasticity, and resistance to shrinkage during laundering. Such testing ensures the Baby Zip Baby Onesie maintains its integrity even after multiple washes.

For zippers specifically, durability testing simulates repeated opening and closing cycles to verify long-lasting performance. Additionally, specialized equipment tests the safety of zipper designs, ensuring there are no sharp edges or loose components that could harm infants.

Engineering and manufacturing a newborn onesie like the Baby Zip Baby Onesie is no small feat. A precise understanding of key factors such as GSM, fabric density, and the role of state-of-the-art industrial machinery ensures a product that delivers unmatched quality, safety, and reliability. From the selection of hypoallergenic materials to the use of precision-driven weaving, cutting, and sewing technologies, every step in the production process is designed to meet the highest standards.

As a B2B stakeholder, leveraging these insights can help your business scale efficiently, reduce waste, and bring innovation to the baby clothing market. The Baby Zip Baby Onesie stands as an exemplary testament to what technology and meticulous engineering can achieve in creating garments designed with both parent and baby in mind.

| Fabric Type | Organic Bamboo |

| Compliance | GOTS Organic |

| Customization | ODM |

| Lead Time | 22 Days |