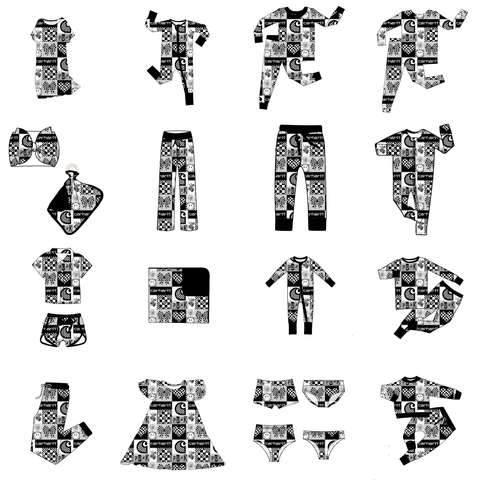

Bespoke Secret Stock Receive Baby Bamboo Pajamas Character Items Baby Shortie Random Size And Color Zippy For Kids Cpsia Compliant Wholesale

Exploring the Fabric Engineering Behind Baby Bamboo Pajamas

In the competitive world of children's clothing, comfort, sustainability, and quality are key factors that distinguish premium brands from the rest. This article delves into the innovative engineering behind baby bamboo pajamas, particularly focusing on GSM (grams per square meter), fabric density, and the industrial machinery used in their manufacture. We will explore the secrets of these special stock items featuring baby shorties and zippy designs in random sizes and colors.

The Science of GSM and Fabric Density

The comfort and durability of baby pajamas significantly hinge on the fabric's GSM and density. GSM refers to the weight of the fabric per square meter, and it is a crucial determinant of the garment's quality. Bamboo fabric for baby pajamas typically ranges between 150 to 200 GSM, offering a fine balance of softness and durability.

Fabric density, on the other hand, refers to the compactness of the fibers within the textile. For children's apparel, a higher density is often preferred because it increases durability without sacrificing softness—essential characteristics when designing garments for toddlers who are always on the move.

Bamboo: A Sustainable Fabric Choice

Utilizing bamboo as the primary material for baby pajamas leverages both environmental and functional benefits. Bamboo grows rapidly without the need for pesticides, making it an eco-friendly choice. Its natural fibers create a breathable fabric that is perfect for regulating temperature, keeping babies cool in the summer and warm in the winter. Additionally, bamboo fabric is hypoallergenic, reducing the risk of skin irritation.

For fabric engineers, transforming bamboo into a textile involves converting bamboo cellulose into fiber through an intricate process that preserves its natural qualities. This guarantees that the fabric maintains its sheen, elasticity, and strength while offering the incredible softness required for baby garments.

Industrial Machinery: Precision in Production

The production of bamboo fabric baby pajamas involves state-of-the-art industrial machinery tailored to preserve fabric integrity. High-precision weaving machines play a significant role by interlacing threads at optimal tension, ensuring that each piece of fabric achieves the desired quality metrics of GSM and density.

| Fabric Type | Organic Bamboo |

| Compliance | CPSIA Compliant |

| Customization | Tailor-made |

| Lead Time | 23 Days |

Knitters and weavers operate in tandem with automated cutting machines that execute patterns with precision, reducing fabric waste—a critical aspect of maintaining sustainability in production. These machines are controlled by sophisticated software that checks for inconsistencies in the fabric, such as thread count variations or GSM deviations, enhancing the end product's quality assurance process.

Character Items, Baby Shorties, and Zippy Design Features

The appeal of baby pajamas extends beyond comfort to include design elements that attract both parents and children. Character items, which often feature beloved storybook or cartoon figures, are a charming addition to these garments. Utilizing digital printing technology, manufacturers can embed colorful and durable designs directly onto the fabric, maintaining softness without adding weight.

Baby shorties and zippy designs, with their functional and stylistic appeal, are crafted with attention to detail. Shorties offer ease of movement, while zippies ensure hassle-free wearability with secure closures. The choice of zippers involves precision manufacturing to avoid any discomfort for the child, employing hidden seams and soft linings.

Random Size and Color Variability

A unique aspect of the secret stock of baby bamboo pajamas is their availability in random sizes and colors—a strategy embraced by manufacturers to appeal to a broader customer base. This approach benefits inventory management by reducing the need for precise stock predictions, allowing for flexibility in meeting varying consumer demands.

Color variability is achieved through the use of eco-friendly dyes that seamlessly integrate with bamboo fabric's natural hues. Industrial dyeing machines apply colors evenly, ensuring vibrancy without sacrificing the fabric's integrity. The randomness in sizing and color also invites a playful surprise element, enhancing the shopping experience.

: Engineering Baby Bamboo Pajamas for Quality and Sustainability

The engineering excellence behind baby bamboo pajamas is a testament to the commitment to quality, sustainability, and innovation in the textile industry. By balancing GSM, fabric density, and utilizing advanced industrial machinery, manufacturers can produce durable and comfortable garments suited for the delicate needs of babies. The combination of character designs, shorties, zippies, and random size and color offerings ensure that these pajamas are not only functional but also a delightful choice for parents and children alike. As the demand for eco-friendly and high-quality children's wear continues to rise, bamboo pajamas stand out as a leading choice, blending science, sustainability, and style.