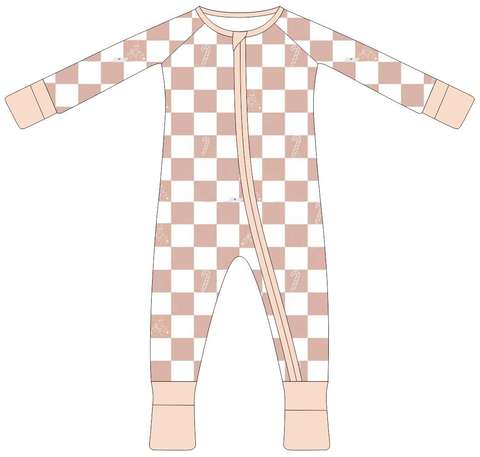

Cpc Certified Bamboo Postpartum Pajama Set Oem Supplier

Innovating Comfort with Bamboo Postpartum Pajama Sets

The demand for postpartum apparel is on the rise, driven by a growing awareness of new mothers’ comfort and care. Among these, bamboo postpartum pajama sets stand out due to their exceptional blend of softness, durability, and eco-friendliness. In this article, we'll investigate how parameters such as GSM, fabric density, and industrial machinery play a critical role in the production of these garments, ensuring both quality and customer satisfaction.

GSM: The Foundation of Fabric Quality

GSM, or grams per square meter, is a key metric used in textiles to determine fabric weight and thickness. It serves as a guideline for manufacturers when developing postpartum pajamas that are simultaneously lightweight and durable. The ideal GSM for bamboo fabrics used in postpartum pajama sets generally falls between 150 and 200 GSM. This range ensures a balance between breathability and durability, making the apparel suitable for both warm and cool climates.

Bamboo fibers inherently exhibit a high tensile strength, meaning that even at lower GSM values, the fabric remains durable while maintaining its lightweight nature. Industrial fabric testing machines, like GSM cutters and gram scales, are used extensively during the production process to ensure consistency. Manufacturers frequently perform quality checks on the fabric across different rolls to avoid discrepancies, as a higher GSM might compromise breathability, while a lower GSM could lead to reduced longevity.

Fabric Density: Comfort Meets Longevity

Fabric density, alongside GSM, is another essential metric in textile engineering. In bamboo postpartum pajama sets, fabric density directly impacts softness, durability, and the drape of the garment. The term "density," in this context, denotes the number of threads or yarns per unit of area. Bamboo fabrics, with their fine fibers, tend to exhibit a high thread and yarn count, ensuring that the final product maintains a smooth texture capable of minimizing skin irritation.

For postpartum pajamas, an optimal thread count lies between 250 and 400 threads per square inch. Too high a density may result in a heavy or overly rigid weave, while too low a density might compromise the structural integrity of the garment. Automated weaving machinery helps maintain precision in achieving the ideal density during the production phase, utilizing cutting-edge technology such as automated loom systems equipped with tension-monitoring sensors.

The Role of Industrial Machinery in Sustainable Production

Producing high-quality bamboo postpartum pajama sets begins with the cultivation of bamboo fibers, but it's the industrial machinery that ensures scalability and consistency. From spinning the raw bamboo material into yarn to weaving the fabric and tailoring the final garment, each step involves precision engineering for quality assurance.

Yarn Spinning Machines: Turning Bamboo into Threads

The production process starts with the transformation of bamboo pulp into yarn. Ring spinning and open-end spinning machines play a crucial role in converting the raw material into fine, uninterrupted threads. These machines control the thickness and strength of the resulting yarn, crucial for the postpartum pajama’s softness and longevity. Precise machinery calibration is essential to handle bamboo fibers, which are known for their smooth surface yet high rigidity under mechanical stress.

Weaving and Knitting Machines: Fabric Formation

Next comes the weaving or knitting stage. Advanced rapier looms and circular knitting machines are widely employed to create the desired fabric structures for pajama sets. For postpartum wear, a jersey knit or interlock structure is often preferred due to its stretchability, softness, and moisture-wicking properties. These machines are equipped with modern features such as electronic control systems, allowing manufacturers to pre-program fabric specifications like elasticity, stitch density, and pattern placement.

Dyeing and Finishing Machinery: Enhancing Fabric Performance

Bamboo fabrics are generally dyed using low-impact, organic dyes supplied through jet-dyeing or soft-flow dyeing machines. These machines limit water consumption while ensuring even coloration, an essential step for meeting the sustainability commitments of most postpartum pajama manufacturers. The finishing process typically involves mechanical or chemical treatments to enhance fabric softness, stretch, and moisture management, all of which are critical for postpartum apparel. Calendering machines are often used to achieve a smooth finish without sacrificing fabric breathability.

The Benefits of Bamboo in Postpartum Pajama Sets

Bamboo postpartum pajamas are prized not only for their sustainability but also for the unique properties they bring to postpartum care. Below are some technical advantages that bamboo fabrics provide:

1. Moisture-Wicking Ability

One of the standout features of bamboo fabric is its moisture-wicking capability, which keeps the skin dry and prevents irritation. This is achieved through the micro-gaps found naturally in bamboo fibers, which enhance absorbency while allowing for quick drying.

2. Antibacterial and Hypoallergenic Properties

Bamboo fibers contain an organic bio-agent called "bamboo kun," which imparts natural antibacterial and antifungal properties. These qualities make bamboo an ideal material for postpartum pajamas, as they reduce the risk of skin irritations and infections, even in humid environments.

3. Temperature Regulation

Bamboo offers excellent thermoregulatory characteristics, keeping the wearer warm during cooler conditions and cool during hotter weather. This is a critical feature for postpartum mothers, who often experience hormonal fluctuations that lead to temperature sensitivity.

Challenges in Scaling Bamboo Pajama Production

Despite their numerous benefits, the production of bamboo postpartum pajamas is not without challenges. One significant concern is the energy-intensive process required to transform bamboo stalks into usable fibers. Although many manufacturers opt for closed-loop processing systems to minimize environmental impact, these systems require sophisticated, high-cost machinery.

Another challenge lies in the precise handling of bamboo fibers during manufacturing, as they are more brittle compared to traditional cotton. This necessitates the use of advanced machinery capable of handling delicate fibers without causing breakage or defects in the final product.

Future Outlook

As driven by consumer demand, the future of bamboo postpartum pajama production is bright. Innovations in textile machinery, such as AI-assisted weaving looms and automated finishing tools, will allow for even higher levels of efficiency and consistency. , research into sustainable mechanical and chemical processes will likely reduce the environmental footprint of bamboo fabric production.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | Private Label |

| Lead Time | 20 Days |

For businesses looking to enter this space, understanding the interplay between GSM, fabric density, and advanced industrial machinery is crucial. These technical details are the backbone of creating premium postpartum apparel that meets the demands of modern consumers for both comfort and sustainability.