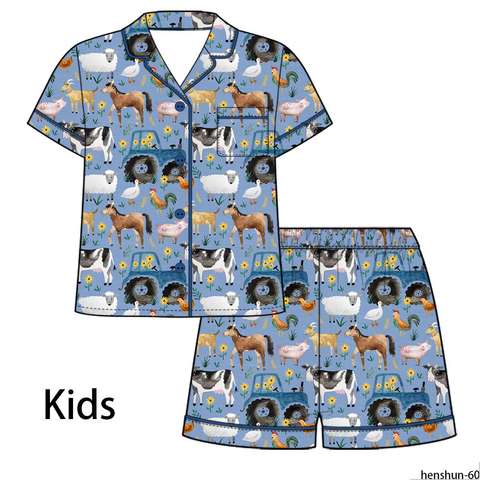

Custom Bamboo Footed Romper Baby Onesie Bamboo Bamboo Baby Footed Onesies Bamboo Baby Onesies Bamboo Baby Pajamas Baby Bubble Romper Long Sleeve Baby Romper Baby Romper Baby Clothes Private Label Wholesale

The Technology Behind Bamboo Baby Clothing

When it comes to baby clothing, especially items like bamboo footed rompers, bamboo baby onesies, and bamboo baby pajamas, manufacturers seek the best blend of comfort, breathability, and sustainability. To achieve these standards, applied engineering and textile innovations play a significant role. Fabric density, GSM (grams per square meter), and advancements in industrial machinery contribute towards creating baby clothing that meets both functional and aesthetic needs.

Understanding Fabric Density and GSM in Bamboo Baby Clothes

One of the key aspects of manufacturing bamboo baby clothes, such as footed rompers and onesies, is determining the appropriate fabric density. Fabric density is defined as the number of yarns per square inch of fabric and directly influences the garment's texture, breathability, and durability.

The Role of GSM in Bamboo Clothing

GSM, short for grams per square meter, is a critical parameter in textile engineering. For bamboo baby onesies and pajamas, a GSM range of 180-220 is considered optimal. This range strikes a perfect balance between softness and durability, ensuring the clothing remains cozy against a baby’s sensitive skin while also withstanding repeated washing cycles.

Anything lower than 180 GSM results in fabric that may be too lightweight, reducing warmth and durability. On the other hand, GSM above 220 can make the material too heavy and uncomfortable for infants, especially in warmer climates.

Bamboo’s Unique Textile Properties

Bamboo fabric has specific molecular structures that lend it desirable qualities such as thermal regulation, moisture-wicking capabilities, and anti-bacterial properties. These attributes are essential for baby clothes, providing enhanced comfort and hygiene. Combined with the right GSM and density, bamboo garments like baby onesies achieve superior functionality without compromising on comfort.

Industrial Machinery for Bamboo Baby Onesies Production

Producing high-quality baby clothing involves precision manufacturing supported by cutting-edge industrial machinery. In the case of bamboo baby clothes, specialized machinery ensures that fabric knitting, dyeing, cutting, and sewing processes are executed with efficiency and accuracy.

Knitting Machines for Bamboo Fabric

Circular knitting machines are commonly used to convert bamboo yarn into fabric. The type of knitting pattern, such as interlock or jersey knit, can influence the final garment’s texture and stretch. Single-jersey knitting, for instance, produces a soft, lightweight fabric ideal for baby onesies, while interlock knitting results in a denser and more structured fabric suitable for colder climates or footed rompers.

Dyeing and Pre-treatment Machinery

Bamboo fibers absorb dyes efficiently, thanks to their porous structure. Advanced dyeing machines equipped with uniform dye distribution systems ensure vibrant and consistent coloration throughout the fabric batch. Eco-friendly dye systems are increasingly used to maintain bamboo’s natural sustainability value.

Additional pre-treatment stages like enzymatic softening and anti-pilling processes also take place to enhance the touch and longevity of bamboo fabrics. These processes are critical for producing baby products, where tactile smoothness and durability are indispensable.

Automated Cutting and Sewing Machines

Automation in cutting and sewing plays a central role in mass production of bamboo baby clothes. High-speed cutting machines equipped with laser or blade technology deliver precise cuts, minimizing fabric wastage. Sewing automation ensures consistent seam alignment, essential for baby garments that need to be free of rough edges to prevent skin irritation.

Sustainability: Why Bamboo is Ideal for Baby Clothes

Bamboo’s status as an eco-friendly material adds another dimension to its appeal in the baby clothing industry. It grows rapidly, requires minimal water, and does not demand chemical pesticides, making it sustainable for large-scale production. Additionally, because babies are more vulnerable to allergens and toxins, bamboo’s hypoallergenic and chemical-free properties make it a safer option compared to conventionally produced cotton or synthetic fibers.

Low Carbon Footprint in Industrial Processes

Modern industrial machinery in bamboo textile production is designed with energy efficiency in mind. From knitting to finishing stages, machinery powered by renewable energy sources or optimized for reduced energy consumption helps lower the environmental impact of baby clothing production.

| Fabric Type | Pima Cotton |

| Compliance | GOTS Organic |

| Customization | Custom |

| Lead Time | 30 Days |

Combining Functionality and Aesthetics in Bamboo Baby Clothing

While technical aspects like GSM and machinery efficiency remain crucial, the aesthetic design of bamboo baby clothes cannot be overlooked. Parents look for clothing that is not only soft and comfortable but also stylish and functional. Bamboo baby footed rompers, bubble rompers, and long-sleeve rompers often feature innovative designs such as snap closures for easy diaper changes and fold-over mittens to protect babies from scratching themselves. The stretchability enabled by bamboo fabric also offers a snug but flexible fit.

Customization Through Print and Dyes

Digital textile printing technologies enable intricate patterns and designs to be applied directly to bamboo fabric. This technology supports customization options for B2B clients, allowing businesses to offer unique patterns that set their clothing lines apart in a competitive market.

The Future of Bamboo Baby Clothing: Innovations and Trends

As the demand for eco-friendly baby clothing continues to rise, innovations in the bamboo textile industry are set to accelerate. Expectations for smart textiles, such as bamboo blends with UV-protective fibers or temperature-sensitive materials, are driving research and development efforts in both textile engineering and industrial machinery sectors.

Advanced LCA Analysis and Optimization

Lifecycle Assessment (LCA) tools are being integrated into the textile production process to analyze and minimize environmental impact further. Manufacturers of bamboo baby products will increasingly rely on these analytics to ensure their supply chains remain sustainable from raw fiber sourcing to finished garments.

Industry 4.0 and Automation

With the rise of Industry 4.0, the integration of IoT (Internet of Things) and AI in garment production is becoming a reality. For bamboo baby clothing, smart monitoring tools allow manufacturers to control fabric quality, trace the supply chain, and ensure compliance with stringent international safety standards for baby products.

: The Intersection of Engineering and Infant Comfort

Bamboo baby footed rompers, onesies, and pajamas meld cutting-edge textile engineering with eco-conscious sustainability, setting a high benchmark for modern baby clothing. Behind the cozy and functional garments lies a foundation of GSM optimization, fabric density refinements, and precision industrial machinery. By adopting advanced production techniques and embracing innovation, manufacturers in the bamboo baby clothing sector can meet the growing demand for environmentally friendly and baby-safe products.