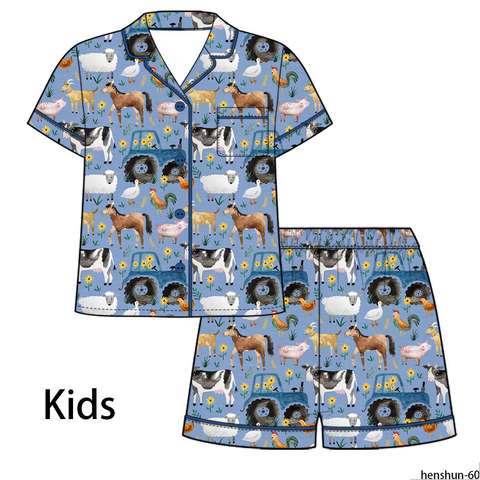

Custom Bamboo Pajamas For Family Astm F963 Factory

Bamboo Pajamas for Family: Combining Comfort, Durability, and Sustainability

Bamboo pajamas are emerging as an innovative solution for families seeking sustainable and comfortable sleepwear. This article delves into the technical aspects of producing bamboo pajamas, including fabric density, GSM (grams per square meter), and the essential industrial machinery that ensures consistent quality. We will explore how advanced fabric engineering meets sustainability to deliver a superior sleeping experience.

Understanding GSM and Its Role in Bamboo Pajamas

The term GSM (grams per square meter) is widely used in the textile industry to refer to the weight of fabric. Understanding this parameter is crucial when designing bamboo pajamas for families, as it impacts comfort, durability, and suitability across seasons. For applications in pajamas, an optimal GSM range is typically between 150-200. Let’s break down the reasons why GSM is pivotal to the manufacturing process.

Impact on Comfort: Bamboo fibers are naturally soft and breathable, but GSM plays a critical role in enhancing or mitigating these intrinsic properties. A lower GSM (around 150) may result in a more lightweight, breathable fabric suitable for warmer climates, whereas a higher GSM (around 200) ensures a thicker, warmer textile suitable for colder areas.

Durability and Longevity: GSM directly correlates with a fabric's durability. For bamboo pajamas intended for family use, where wear and tear may be frequent due to repeated washing cycles, higher GSM ensures improved longevity without compromising softness. This balance is key to consumer satisfaction in a competitive market.

Fabric Density: A Key Player in Bamboo Pajamas Quality

Fabric density refers to the number of threads or fibers woven or knit within a square unit of fabric. While GSM measures weight, fabric density focuses on the compactness of the weave, which has a profound effect on bamboo pajamas. Here are three critical areas influenced by fabric density:

Moisture Management: Bamboo fabrics are celebrated for their moisture-wicking capabilities. A finely tuned fabric density ensures that sweat and moisture are efficiently absorbed and wicked away from the skin, contributing to a more comfortable sleeping experience. Industrial knitting or weaving machinery is calibrated to produce specific densities that maximize this property.

Fabric Drape: The density of a fabric also affects how the material drapes over the body. For family-focused bamboo pajamas, a moderate density optimizes flexibility and movement, essential for ensuring that sleepwear is non-restrictive while maintaining aesthetic appeal.

Air Permeability: One of bamboo fabric’s most sought-after traits is breathability. Tight weaves can impede airflow, undermining the cooling effect of bamboo fabric. Conversely, overly loose weaves can lead to compromised structural integrity. Striking the right balance in fabric density is critical to maintain both comfort and durability.

Industrial Machinery for Bamboo Pajama Production: Precision in Automation

Efficient and precise industrial machinery is at the heart of producing high-quality bamboo pajamas for families. Modern textile manufacturing equipment integrates advanced technology to cater to the unique properties of bamboo fibers. Below, we examine the key machinery involved in the production process:

1. Circular Knitting Machines: These machines are pivotal in creating seamless, stretchable bamboo knit fabrics. For pajamas, the circular knitting process allows for smooth, soft surfaces while preserving elasticity. Automation features, such as auto-lubrication systems and tension control mechanisms, ensure uniform production quality without fiber damage.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | OEM |

| Lead Time | 18 Days |

2. Dyeing and Finishing Machines: Bamboo fabric often undergoes eco-friendly dyeing processes to maintain the sustainability factor. Jet-dyeing machines are commonly used for bamboo fibers due to their ability to evenly distribute dye while preserving fabric integrity. Fabric finishing machinery then enhances characteristics like softness, anti-pilling, and crease resistance, which are essential for pajamas.

3. Cutting and Sewing Automation: State-of-the-art laser cutting solutions enable precision tailoring of pajama patterns. Automated sewing lines equipped with multi-needle chain stitch machines further ensure consistently strong seams that can withstand extensive use without fraying or tearing. This is particularly important for children’s pajamas, which endure more frequent washing and wear.

Sustainability and Scalability in Bamboo Pajama Production

Sustainability remains a driving force in the rising demand for bamboo-based textiles. Bamboo, as a raw material, offers numerous environmental advantages, including rapid renewability, minimal water requirements, and no need for chemical pesticides. However, sustainably sourcing bamboo and refining its fibers at scale require specialized know-how and efficient manufacturing systems.

Sustainable Fiber Extraction: The process of converting bamboo into viscose fibers involves breaking down bamboo pulp into cellulose through chemical and mechanical processes. To meet sustainability goals, many manufacturers are investing in closed-loop systems that capture and reuse solvents, minimizing environmental impact.

Scalability and Quality Control: Producing bamboo pajamas at scale without compromising quality necessitates advanced industrial processes and quality checkpoints. Automated inspection systems equipped with AI and machine vision play an essential role in identifying defects in fabric or seams early in the production cycle. Systems like these reduce waste, ensuring both economic and environmental benefits.

Certifications and Market Adaptability: To meet international and regional market demands, manufacturers must comply with sustainability certifications such as OEKO-TEX®, GOTS (Global Organic Textile Standard), and FSC (Forest Stewardship Council). Adhering to these standards boosts consumer trust and enables entry into environmentally conscious markets.

: A Bright Future for Bamboo Pajamas

The production of bamboo pajamas for families represents a perfect convergence of comfort, sustainability, and technological innovation. By leveraging optimal GSM, precisely calibrated fabric density, and advanced industrial machinery, manufacturers can create high-quality sleepwear that appeals to eco-conscious consumers. , the scalability and adaptability of modern production systems ensure that bamboo pajamas are not only accessible but also maintain their premium feel and durability.

For B2B buyers and distributors in the textile and apparel sectors, bamboo pajamas signify a forward-looking investment. They cater not only to current market trends but also to future demands for sustainable and ethically produced textiles. By collaborating with the right partners and adopting cutting-edge technology, businesses can seize the opportunity to become leaders in this growing market segment.