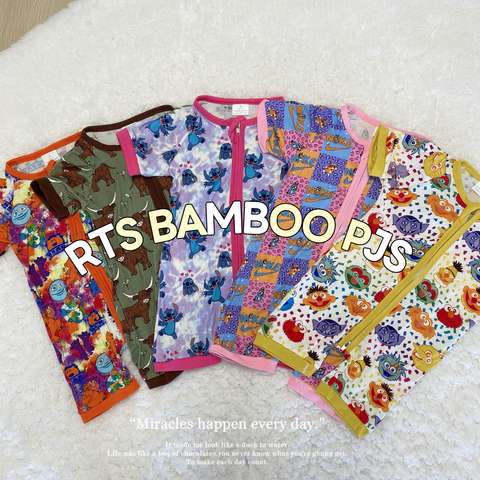

Gots Organic Bamboo Adult Pajama Custom Print Cpc Certified Vendor

Bamboo Adult Pajamas: Precision in Custom Printing and Manufacturing

In today’s textile market, bamboo fabric has emerged as a leading choice for sustainable, comfortable, and versatile apparel. Bamboo adult pajamas are particularly popular for their softness, breathability, and eco-friendly properties. For businesses exploring custom printing for bamboo pajamas, understanding the interplay between fabric density, GSM (grams per square meter), and industrial machinery is critical. This article dives into the technical considerations required to ensure your product delivers comfort, durability, and aesthetics while maintaining production efficiency.

What Makes Bamboo Fabric Ideal for Pajamas?

Bamboo fabric is derived from the pulp of bamboo plants, which undergoes a viscose process to produce a textile fiber. What makes bamboo ideal for adult pajamas lies in its unique combination of properties, including:

- Softness: Bamboo fabric has a smooth texture similar to silk, making it highly comfortable against the skin.

- Breathability: Its moisture-wicking properties enhance air circulation, keeping wearers cool and dry.

- Antibacterial and Hypoallergenic: Bamboo naturally resists bacterial growth and allergens, making it ideal for those with sensitive skin.

- Eco-Friendliness: Bamboo grows rapidly, requires minimal water, and thrives without pesticides, offering a sustainable alternative to cotton and synthetic fabrics.

Given its exceptional features, businesses producing custom bamboo pajamas must carefully balance aesthetic customization with maintaining the fabric’s inherent benefits. This requires a clear understanding of density, GSM, and the precise selection of industrial printing machinery.

Understanding Fabric Density and GSM for Bamboo Pajamas

Fabric density and GSM serve as critical parameters in ensuring optimal comfort, durability, and performance. GSM, specifically, measures the weight of fabric in grams per square meter and is a key metric that directly correlates with fabric quality.

The Role of GSM in Bamboo Pajamas

For adult bamboo pajamas, GSM typically falls in the range of 150 to 250, depending on the intended use:

- Lightweight Pajamas (150-180 GSM): Ideal for warmer climates, offering a breathable and airy feel.

- Midweight Pajamas (180-220 GSM): Versatile pajamas suitable for most environments, balancing comfort and durability.

- Heavyweight Pajamas (220-250 GSM): Perfect for colder weather, adding thickness and warmth without compromising on softness.

As GSM increases, the fabric becomes denser and more resilient, but with slightly reduced breathability. Manufacturers must select the appropriate GSM based on the target market and climate conditions, ensuring the pajamas remain comfortable yet durable.

The Importance of Fabric Density

Fabric density is the number of threads or yarns packed within a specific area of the fabric. Bamboo fabric with higher densities ensures better durability and resistance to pilling and wear, which is essential for adult loungewear that undergoes repeated wash cycles. However, high-density fabrics can reduce comfort and stretchability. A balanced density that complements the selected GSM is essential for achieving an optimal blend of comfort, elasticity, and longevity in bamboo pajamas, especially when further processes like custom printing are applied.

Custom Printing Considerations for Bamboo Fabric

Custom prints turn standard bamboo pajamas into unique, high-value products designed to meet consumer preferences. However, bamboo fabric requires distinct handling and precision in the printing process to preserve its inherent softness and performance attributes. Several printing methods are suitable, each with its respective advantages depending on the intended design and scale of production.

Screen Printing for Bamboo Pajamas

Screen printing is a traditional method that excels in creating bold, vibrant designs. Using mesh screens, ink is applied layer by layer onto the bamboo fabric. While highly durable and cost-effective for large-scale production runs, there are some challenges to note:

- The porous nature of bamboo fabric requires the use of specialized water-based or eco-friendly inks to maintain softness.

- Printing on high-GSM fabric necessitates adjustments in mesh tension and ink viscosity to ensure even application.

Screen printing is an excellent option for businesses producing bamboo pajamas with simple designs and minimal color variations.

Sublimation Printing for Bamboo Pajamas

Sublimation printing is another popular method, particularly for intricate, full-color designs. This process involves transferring designs onto fabric using heat-activated dyes. Sublimation bonds with the fibers at a molecular level, ensuring long-lasting, high-resolution prints. However, there are specific considerations for bamboo:

- Sublimation printing works best on fabrics with a high polyester content. For bamboo-polyester blends (e.g., 70% bamboo, 30% polyester), it is a viable option, but pure bamboo may not achieve the same vibrant results.

- The heat involved in sublimation could impact the structural integrity of bamboo fabrics, so careful temperature control is required.

Sublimation provides excellent customization flexibility, especially for businesses targeting detailed or gradient-heavy designs on bamboo pajamas.

Direct-to-Garment (DTG) Printing for Bamboo Pajamas

Direct-to-Garment (DTG) printing has gained traction for its ability to reproduce photographic-quality images on fabric seamlessly. DTG printers use specialized water-based inks designed to penetrate natural fibers like bamboo.

Considerations for DTG on bamboo include:

- Pre-treatment of fabric to enhance ink absorption and adherence, ensuring bright and detailed results.

- The need for lower ink curing temperatures to prevent damaging the bamboo fibers.

DTG is particularly useful for fulfilling smaller-batch or on-demand orders where complex, multi-colored designs are required.

The Role of Industrial Machinery in Bamboo Pajama Production

Scaling the production of bamboo adult pajamas with custom prints relies on advanced industrial machinery designed for precision and efficiency. Selecting the right equipment ensures consistent quality, high throughput, and cost-effectiveness.

Fabric Knitting Machines

The production process for bamboo pajamas often begins with raw bamboo fibers being converted into yarn and knitted into fabric. Circular knitting machines are commonly employed for producing smooth, soft, and stretchable bamboo knits that align with the unique properties desired in pajamas. Selecting machines with variable configuration settings allows manufacturers to produce fabrics of different GSM and densities based on customer and market demands.

Textile Printers

As discussed earlier, the customization phase requires precise textile printing machines. Industrial-grade DTG printers or screen printing machines equipped with advanced automation features can streamline production, especially for high-volume orders. Additionally, integrating pre-treatment stations with DTG printers can enhance productivity by minimizing manual handling.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | OEM |

| Lead Time | 16 Days |

Fabric Inspection and Finishing Machines

After knitting and printing, fabric inspection machines play a critical role in identifying defects, such as uneven thickness or poorly applied prints. Modern inspection systems often include high-resolution cameras and AI-based defect detection. Post-inspection, finishing machines further refine the fabric by stabilizing its texture and ensuring excellent surface quality to meet customer expectations.

: The Future of Bamboo Pajama Manufacturing

The combination of eco-conscious materials, advanced customization methods, and high-precision industrial machinery positions bamboo adult pajamas as a thriving product category in the textile industry. By understanding the nuances of GSM, fabric density, and printing methods, businesses can deliver high-quality pajamas that offer exceptional comfort, durability, and visual appeal. Leveraging industrial-grade machinery allows manufacturers to scale production efficiently while maintaining the integrity of the bamboo fabric and the quality of the custom prints.

As consumer demand for sustainable, personalized products continues to rise, investing in the right materials and technology will ensure a competitive edge in the market. Whether you’re aiming for bold screen-printed designs or intricate DTG patterns, the possibilities with bamboo custom-printed pajamas are endless, making it a lucrative opportunity for forward-thinking manufacturers in the textile industry.