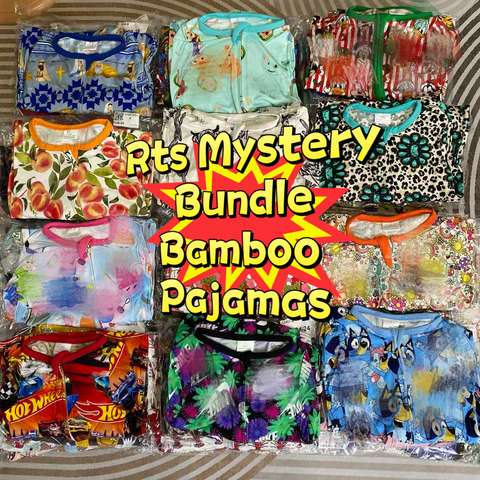

Gots Organic Bamboo Chritmas Pajamas For Family Odm Vendor

The Convergence of Comfort and Sustainability in Bamboo Christmas Pajamas

As B2B supply chains increasingly prioritize eco-friendly practices, bamboo Christmas pajamas for families have emerged as a novel and sustainable product offering. Bamboo fabric, known for its breathable and thermal-regulating qualities, has been a key player in the textiles industry. In this article, we’ll dive into the GSM ratings, fabric density specifics, and industrial machinery utilized in producing bamboo family pajama sets—with a focus on Christmas-themed designs.

Understanding GSM in Bamboo Fabric

GSM, or grams per square meter, is a critical measurement within textiles to evaluate fabric weight and density. For bamboo Christmas pajamas, manufacturers generally aim for GSM ratings between 180 and 240. These values strike the perfect balance of lightweight breathability and thermal insulation suitable for holiday wear.

Lower GSM values, typically between 150 and 180, result in thinner fabric that is suitable for warm environments but may lack sufficient coverage for colder seasons. Families looking for Christmas pajamas with warmth as a priority would prefer thicker fabric with GSM thresholds above 200. This ensures that bamboo’s inherent thermal-regulating property is leveraged effectively without compromising comfort.

Additionally, GSM impacts durability. In industrial manufacturing settings, fabric with lower GSM values may require reinforcement techniques during sewing and cutting to avoid tearing, especially when working with bamboo fibers renowned for their softness and smooth texture.

The Role of Fabric Density in Bamboo Pajamas

Fabric density is another essential technical aspect influencing the production of bamboo holiday-themed pajamas. Density refers to the arrangement and closeness of yarns within the fabric. Bamboo textiles often have a tight weave structure, contributing to smoother surfaces and better resistance to wear over time.

For pajamas designed for family use, the sweet spot of fabric density lies in producing a material that stretches well but retains its form. Industrial-grade knitting machines allow manufacturers to optimize density by adjusting tension during the weaving or knitting process. Bamboo fibers typically excel at moisture absorption, which can be factored into achieving optimal density that doesn’t sacrifice comfort for performance.

Additionally, bamboo’s naturally breathable material responds well to specialized knitting techniques, such as interlock weaves, which enhance elasticity. Such density-focused engineering ensures that pajamas retain warmth during cool December evenings while also being lightweight enough for indoor comfort.

Industrial Machinery Tailored for Bamboo Fabric Production

The production of bamboo family pajamas involves intricate machinery tailored to handle the unique properties of bamboo fibers. Bamboo fabric manufacturing demands precision and adaptability, which modern industrial processes provide. Below are three specialized machinery types pivotal to this production:

1. Carding Machines

Carding machines are at the forefront of producing bamboo textiles. As bamboo fibers undergo transformation from raw material to yarn, carding machines align and clean the fibers. These machines ensure a smooth and uniform distribution of fibers, which is a critical first step in developing high-quality yarn for dense bamboo fabric.

Increased automation in modern carding machines allows manufacturers to scale efficiently, especially during peak production periods like Christmas. Automated systems monitor fiber thickness and consistency to achieve standardization, ensuring the final fabric maintains uniform GSM ratings and density.

2. Circular Knitting Machines

Circular knitting machines help produce seamless fabric suitable for pajamas while enhancing production speed. Bamboo yarn runs efficiently through these machines to create weaves or knits depending on the pajama design specifications. Circular knitting machines are especially valuable for creating Christmas-themed patterns or designs, as they can integrate colored threads seamlessly into the fabric.

These machines are versatile, allowing operators to adjust settings for density, stretch properties, and texture. For bamboo fabrics, this adaptability ensures the final product meets both aesthetic and functional needs—making the pajamas soft, comfortable, and visually appealing for family wear.

3. Heat Setting Machines

Heat setting machines are essential for stabilizing the bamboo fabric once the sewing and knitting processes are complete. Bamboo fibers benefit from heat treatment to retain their shape and elasticity, enhancing the pajamas' durability and longevity. Especially for Christmas pajamas featuring intricate designs or stitched patterns, heat setting ensures that the fibers resist shrinkage even after multiple washing cycles.

| Fabric Type | Organic Bamboo |

| Compliance | GOTS Organic |

| Customization | Private Label |

| Lead Time | 35 Days |

Modern heat setting machinery allows manufacturers to regulate temperature with pinpoint precision. This minimizes fiber damage while maintaining the natural softness of bamboo material—a key selling point for family pajamas. Additionally, heat treatment can help lock in dyes used for producing festive Christmas colors like red, green, and white.

Advanced Refinements in Bamboo Pajama Fabrication

Beyond machinery and GSM standards, manufacturers are exploring advanced refinements to elevate bamboo Christmas pajamas. These include chemical textile finishing treatments and computerized pattern designs. Such developments enhance product performance, visual appeal, and end-user satisfaction.

Textile Finishing for Bamboo Pajamas

Textile finishing techniques, such as enzymatic treatments, help refine bamboo fabrics by softening fibers further while maintaining their eco-friendly profile. Enzymes break down rougher portions of bamboo material, resulting in a luxuriously smooth touch. This treatment is particularly useful for family pajamas where comfort is a priority.

In addition, finishing processes can apply non-toxic dyes to bamboo fabrics, ensuring vibrant Christmas-themed color schemes. From bright holiday reds to cozy greens, textile finishing technology supports precision dyeing that doesn’t negatively impact the material’s performance.

Computerized Pattern Integration

Computerized pattern integration is becoming a standard for designing family pajama sets. Advanced CAD (Computer Aided Design) software enables manufacturers to program machines for creating intricate patterns, such as snowflakes, reindeer, or festive lettering. For bamboo pajamas, this process ensures precise placement and accurate replication of patterns across each set produced.

Bamboo fibers respond well to digital printing processes due to their absorbent nature. Manufacturers can maximize efficiency with precise pattern application, resulting in Christmas pajama sets that are both beautiful and uniform across multiple batches.

: Engineering Bamboo Pajamas for Holiday Comfort

From GSM optimization to industrial machinery, the production of bamboo Christmas pajamas is a technically rich and innovative process. Balancing fabric density, leveraging advanced knitting machines, and utilizing precision finishing techniques allows manufacturers to create eco-friendly, high-performance family pajama sets. As demand soars for sustainable textiles, bamboo continues to be a leading material for cozy winter nights, combining comfort, functionality, and an eco-conscious ethos.

For B2B partners in the textiles industry, bamboo Christmas pajamas offer an exciting opportunity to deliver holiday cheer in a sustainable way. Leveraging industrial innovations and engineering excellence ensures that these pajamas stand out—not just for their festive appeal but also for the technical mastery behind their creation.