Odm Kids Bamboo Clothing Private Label Supplier

The Role of GSM and Fabric Density in Kids Bamboo Clothing

In the textile industry, fabric quality plays a pivotal role in distinguishing premium products from their lower-tier counterparts. This is particularly important in kids' bamboo clothing, where comfort, durability, and sustainability need to be balanced. Two key factors critical to this equation are GSM (grams per square meter) and fabric density. Both directly influence the tactile experience, thermal regulation, and structural integrity of the final product.

Understanding these technical elements helps producers and buyers alike make informed decisions in the B2B supply chain. , the use of innovative industrial machinery ensures consistent, efficient, and high-quality output. Below, we dive deeper into the technical specifics of bamboo fabric production, focusing on GSM, fabric density, and the machinery that powers this sector.

What is GSM and Why is It Important?

GSM, or grams per square meter, is a standard industry measurement used to define the weight of fabric per unit area. This parameter serves as a critical indicator of quality, durability, and softness. For children's bamboo clothing, striking the right GSM value is crucial to ensure optimal comfort and suitability for sensitive skin.

For summer-specific wear, GSM values for bamboo fabrics often range between 180 and 220, offering lightweight properties perfect for breathability and moisture wicking. Conversely, winter bamboo garments usually use higher GSM fabrics, around 260-320, to provide warmth and insulation. The choice of GSM directly impacts the functionality of the clothing—lighter fabrics for breathability and thicker options for thermal management.

Industrial textile machines, such as automated knitting and weaving machines, can control GSM during production with exceptional precision. These machines adjust yarn tension, weave tightness, and material input to produce a consistent weight, ensuring every roll of fabric meets the specified GSM requirement. High-tech settings allow for seamless calibration, reducing waste and enhancing efficiency in production lines.

The Link Between Fabric Density and Performance

Fabric density complements GSM as another critical factor in the production of kids’ bamboo clothing. While GSM measures the weight, fabric density refers to the number of threads or fibers packed into a given area of fabric. In technical terms, it is the number of warp and weft yarns per square inch in woven fabric or the course and wale count in knit fabric.

Bamboo fabric with a higher density tends to be more durable and resistant to abrasions—essential for children's garments exposed to frequent rough-and-tumble activities. However, higher density can compromise breathability and flexibility, so manufacturers must find an optimal balance by leveraging industry expertise and precision machinery.

Highly automated industrial processes such as computerized looms and circular knitting machines enable adjustable density parameters, ensuring consistency and precision in weaving or knitting bamboo fibers. Modern equipment can easily handle fine-tuning density specs, making it simpler to meet specific customer needs while maintaining production efficiency.

The Challenge of Maintaining Consistency

Consistency in GSM and fabric density remains a challenge without robust quality monitoring. Variations in bamboo fiber characteristics, yarn quality, and spinning techniques can affect the desired results. Advanced industrial machinery equipped with real-time monitoring systems is imperative for achieving precision.

The Production Process: Industrial Machinery in Bamboo Textile Manufacturing

The production of high-quality kids bamboo clothing relies on specialized industrial machinery. From the initial processing of raw bamboo fibers to weaving or knitting them into fabric, every stage requires attention to detail and state-of-the-art technology. The combination of efficient processes and intelligent automation systems transforms natural bamboo into fabrics that meet the stringent needs of children’s wear.

Bamboo Fiber Yield and Preparation

Before bamboo can be transformed into fabric, the plant undergoes extensive processing to extract cellulose. The most commonly employed method is the viscose process, where bamboo is chemically treated to produce a viscose solution. This is then spun into thread or yarn for further processing.

Advanced machinery such as carding machines plays a vital role in this stage. These machines ensure that the bamboo fibers are cleaned, disentangled, and aligned before their conversion to yarn. Proper preparation is crucial, as it dictates not only the smoothness of the resulting fabric but also its absorption properties and elasticity.

Knitting or Weaving for Optimal Fabric Properties

Once bamboo yarn is prepped, it is processed using either knitting or weaving techniques to create fabric. In both cases, industrial machines dominate the scene for their precision, productivity, and ability to handle large-scale orders.

- Knitting Machines: Circular or flatbed knitting machines are commonly used for bamboo textiles designated for kids’ clothing. These machines produce stretchable, soft, and breathable fabrics with consistent performance properties.

- Weaving Machines: Industry-grade power looms are employed to weave bamboo into densely packed fabrics. Air-jet looms and rapier looms can handle complex designs and consistently maintain fabric density specifications.

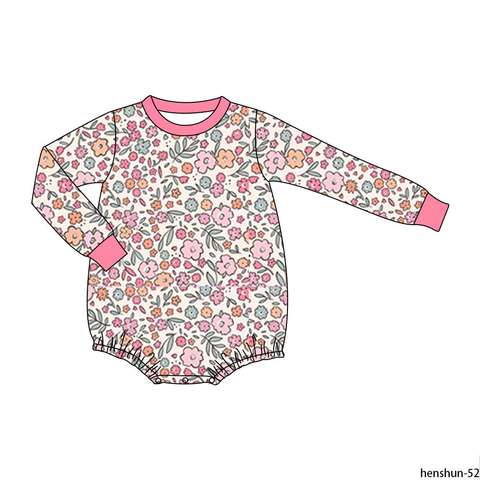

The choice between knitting and weaving often depends on the end application of the fabric. For instance, stretchy and breathable bamboo jersey is perfect for T-shirts, onesies, and sleepwear, all of which are ideal for active kids. On the other hand, woven bamboo fabrics are a good choice for more structured items like pants or jackets.

Quality Assurance and Advanced Monitoring

In the fast-paced world of industrial textile manufacturing, maintaining quality without compromising production speed is critical. This is especially relevant in the production of kids’ bamboo clothing, where stringent safety standards and tactile comfort requirements dominate.

Modern factories employ machinery equipped with advanced sensors, which monitor and adjust parameters in real time. Smart software integrated with these machines can accurately track the GSM, fabric density, and even moisture content to maintain uniformity across production batches.

Additionally, automated inspection systems scan the fabric for anomalies such as uneven yarn tension, dye streaks, and weak points caused by improper weaving or knitting. Such advancements reduce wastage, save time, and uphold the high quality that discerning B2B buyers demand.

A Sustainable and Growing Market

As sustainability continues to drive consumer preference, the demand for bamboo clothing—especially for children—is on the rise. Bamboo, as a raw material, offers several eco-friendly advantages being a rapidly renewable resource, requiring minimal water, and growing without pesticides. When coupled with the sophisticated textile machinery available today, these sustainable fabrics can be scaled effectively for mass production.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | OEM |

| Lead Time | 37 Days |

Environmental Impact Reduction

The use of cleaner technologies, such as water-efficient dyeing and closed-loop chemical systems in the viscose process, contributes further to reducing the carbon footprint of bamboo fabric production. Investments in energy-efficient industrial machinery also provide long-term benefits in reducing operational costs and emissions.

Growing Adoption in the B2B Segment

The B2B textile sector is increasingly viewing bamboo as a future-forward material. Manufacturers and distributors of kids' fashion are eager to integrate eco-conscious fabrics into their collections, recognizing growing demands for ethical products from retailers and end-consumers. Investments in cutting-edge industrial technology can help producers meet regulatory demands while satisfying a growing market.

Market Forecast and Trends

Market reports indicate a steady rise in demand for sustainable textile products, particularly in the children’s clothing segment, which is projected to grow at a CAGR of over 5.6% in the coming years. The advantages of bamboo fabric—its sustainability, hypoallergenic properties, and luxurious texture—are key drivers making it a preferred choice among manufacturers and retailers alike.

In the competitive landscape of B2B textile manufacturing, producing premium kids bamboo clothing requires a thorough understanding of GSM, fabric density, and the strengths of industrial machinery. These factors not only influence the quality, durability, and comfort of the garments but also determine production efficiency and sustainability.

As consumer awareness of sustainable products continues to grow, leveraging advanced machinery and remaining compliant with environmentally friendly practices becomes more critical for businesses in this sector. By focusing on these pillars of quality and sustainability, manufacturers can meet the expectations of business clients and end consumers, securing a strong position in the evolving textile market.