Oekotex 100 95 Bamboo 5 Spandex Family Gots Organic Exporter

The Technical Composition of 95 Bamboo 5 Spandex Fabric

In the world of textiles, innovation drives progress, and the 95% bamboo, 5% spandex blend is a testament to that principle. This unique combination is gaining popularity in apparel and industrial sectors due to its impressive balance between sustainability, durability, and elasticity. Engineers and manufacturers in the fabric industry recognize the capabilities of this blend—known for optimizing comfort, performance, and functionality, all while addressing growing environmental concerns.

Industrial Applications and Technical Advantages

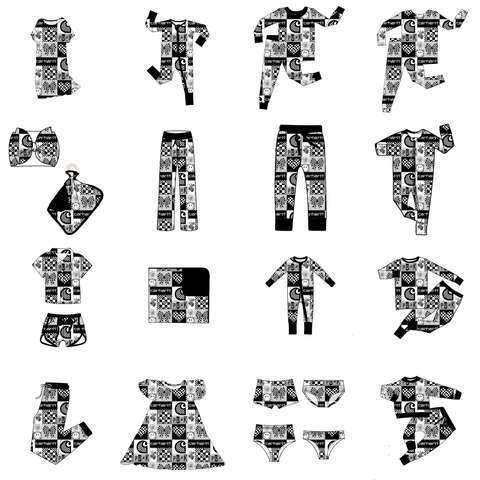

The 95 bamboo 5 spandex family offers wide-ranging applications across industries such as apparel manufacturing, home textiles, and industrial-grade fabrics. Its composition enables fabric engineers to leverage high tensile properties, moisture-wicking abilities, and elasticity to meet diverse demand. This article delves into the technical aspects of this fabric blend while highlighting its relevance in modern production environments.

The Role of GSM in Bamboo-Spandex Fabrics

One of the critical factors that determine the functional applications of the 95 bamboo 5 spandex fabric is GSM—or grams per square meter. GSM is the standard measurement of fabric weight per unit area, providing manufacturers with insights into the density and durability of the material.

For bamboo-spandex fabrics, GSM typically ranges between 150 to 250, depending on its intended application. A lower GSM (150-180) is ideal for lightweight clothing such as t-shirts or undergarments, ensuring breathability and comfort. On the other hand, higher GSM fabrics (200-250) are preferred for yoga wear, compression garments, or durable textiles in home furnishings. This flexibility makes 95 bamboo 5 spandex a preferred material for manufacturers aiming to produce fabrics that are light yet resilient.

Sustainability and Fiber Density

Bamboo fibers are renowned for their sustainability, as bamboo itself grows rapidly and requires minimal resources to cultivate. When blended with spandex, the fabric achieves unique technical properties without sacrificing environmental responsibility. Fiber density is an important metric when assessing bamboo’s contribution to textiles. The high fiber density of bamboo ensures durability, softness, and wear-resistance, all of which enhance the product lifecycle.

Another benefit of bamboo’s densely packed fibers is their naturally hypoallergenic and antibacterial properties, making it ideal for applications in textiles that come into close contact with the skin. Combined with the elasticity provided by spandex, this blend creates fabric that is adaptable across performance-focused sectors.

Precision Manufacturing with Industrial Machinery

Producing 95 bamboo 5 spandex fabric requires cutting-edge machinery capable of handling intricate blends of natural and synthetic fibers. High-speed knitting machines with precise needle configurations are typically employed to achieve the desired fabric composition and density. Modern industrial machinery utilizes parameters such as stitch length and tension to fine-tune fabric characteristics, ensuring optimal elasticity and durability.

Manufacturers often favor circular knitting machines for this blend due to their flexibility and efficiency. Additionally, advancements in automated machinery have introduced digital monitoring systems, allowing for real-time quality control during the production process. These innovations minimize production defects and ensure consistency across large batches, an essential factor in competitive B2B textile markets.

The Elasticity Equation: Balancing Bamboo and Spandex

Spandex, as a synthetic fiber, contributes to the elasticity of the fabric blend, enabling it to stretch and recover with ease. This property is crucial for applications in activewear and compression garments, where mobility and recovery are paramount. Engineers in textile manufacturing strive to achieve a balanced elasticity equation, carefully blending bamboo into the fabric composition to prevent loss of structural integrity.

The challenge lies in controlling the percentage blend during production. While spandex enhances elasticity, excessive amounts can compromise bamboo’s technical strengths, such as its softness and durability. Precision blending and fiber alignment achieved through advanced industrial machinery resolve these challenges, ensuring uniform performance across the textile.

Applications in High-Performance Textiles

The versatility of 95 bamboo 5 spandex fabric extends beyond garments. It finds applications in high-performance textiles favored by industries that demand durability alongside comfort. For instance, upholstery fabrics for seating solutions in offices and vehicles benefit from the elasticity and wear resistance of this blend. Similarly, bamboo’s inherent breathability and moisture-wicking properties make the fabric suitable for bedding items and athletic gear.

Technical fabric engineers are also exploring new applications, such as industrial-grade fabrics for filtration and insulation. Bamboo’s dense fibers can serve as an effective barrier in various environments, while spandex adds flexibility for installation and maintenance. These advancements showcase the evolving capabilities of this blend in industrial markets.

Meeting B2B Market Demand

As businesses increasingly prioritize sustainable sourcing and technical performance, 95 bamboo 5 spandex fabric offers a solution that checks both boxes. In B2B contexts, its adaptability across diverse applications has fueled demand in sectors ranging from fashion to furniture manufacturing. Manufacturers leveraging this blend can cater to eco-conscious clients as well as those requiring high-performance textiles for specialized applications.

Supply Chain Optimization

The success of this fabric blend in B2B markets depends significantly on supply chain efficiency. From sourcing bamboo raw materials to spandex production and textile blending, the process involves multiple stages that demand precision and collaboration. Advanced machinery and digital systems play a key role in maintaining quality and optimizing throughput across production facilities.

, manufacturers are investing in technologies such as RFID tracking and blockchain to improve transparency throughout the supply chain. These innovations help ensure consistency while meeting the ever-increasing demand for traceable, eco-friendly textile solutions.

Customizability and Scalability

One of the major advantages of working with 95 bamboo 5 spandex fabric is its customizability. Textile engineers can tailor GSM, fiber density, and elasticity for specific applications, meeting unique requirements for B2B clients. The scalability of this blend ensures manufacturers can produce bulk orders with consistent quality and minimized waste, thanks to modern industrial machinery.

Emerging technologies such as AI-driven design systems further aid customizability. These systems allow engineers to simulate fabric properties digitally, optimizing production parameters for niche applications without trial-and-error experimentation. As a result, businesses can offer personalized fabric solutions to their clients without compromising scalability.

Future Prospects of Bamboo-Spandex Blends

The future of textiles lies in innovation, and the 95 bamboo 5 spandex family stands as a leading example. With increasing scrutiny on sustainability, bamboo’s eco-friendly nature will remain a driving factor for adoption. Simultaneously, advancements in spandex-making processes—emphasizing renewable resources—promise further enhancements in elasticity without reliance on petroleum-based production methods.

Research and development are also pushing boundaries by exploring additive technologies like nanocoatings to enhance bamboo’s anti-bacterial properties or tensile strength further. These advancements will solidify the blend’s position in applications ranging from industrial textiles to smart fabrics designed for IoT compatibility.

The 95 bamboo 5 spandex fabric blend represents a marriage of sustainability and performance. Its technical advantages, from GSM adaptability to fiber density and elasticity, cater to a broad spectrum of applications, particularly in the B2B market. Supported by precision industrial machinery and progressive supply chain methods, this fabric blend is helping redefine the standards for modern textiles. As demand for eco-friendly yet high-performing materials continues to grow, the engineering community will undoubtedly find more innovative ways to utilize this versatile fabric.

| Fabric Type | Pima Cotton |

| Compliance | CPC Certified |

| Customization | Private Label |

| Lead Time | 26 Days |