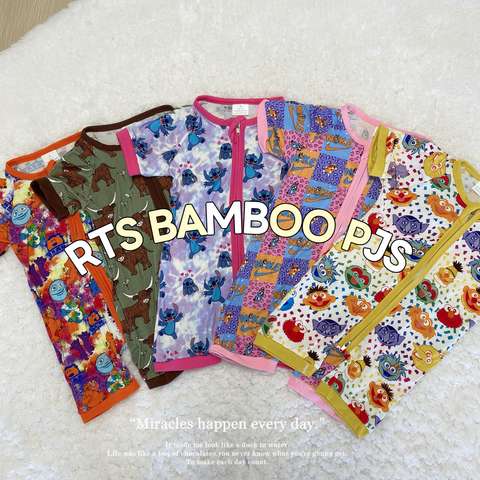

Oekotex 100 Kids Bamboo Pajamas Mystery Box 2T5T Custom Vendor

Unveiling the Mystery: The Science Behind Kids Bamboo Pajamas in Sizes 2T-5T

In the rapidly evolving world of children's apparel, innovation and comfort stand at the forefront, especially when it comes to delicate bedtime wear for toddlers and young children. The introduction of kids' bamboo pajamas, particularly those offered in the intriguing 'mystery box' format, has piqued interest not only from caregivers but also from industry professionals focused on textiles and machinery. This article dives into the technical aspects of these bamboo pajamas, with an emphasis on GSM, fabric density, and the machinery involved in their production.

The Appeal of Bamboo Fabric for Kids' Pajamas

Parents and guardians are increasingly seeking clothing options that balance comfort, sustainability, and safety for their children. Bamboo fabric emerges as a top contender due to its soft texture, hypoallergenic properties, and environmental benefits. Bamboo is favored in the kids' apparel sector for its ability to regulate temperature and ensure a gentle touch against sensitive skin. But what makes bamboo material specifically suited for kids' pajamas, and how do GSM and fabric density play a role?

Understanding GSM in Bamboo Pajamas

Grams per Square Meter (GSM) is a critical parameter in assessing the quality and comfort of fabrics. In the context of bamboo pajamas, GSM is indicative of the fabric's weight and density. A higher GSM often translates to thicker, more insulating material—ideal for colder climates—while a lower GSM offers lightweight, breathable garments perfect for warm weather. For children’s pajamas, a balanced GSM that maintains warmth without overheating is preferred, typically ranging between 150-200 GSM. This range ensures that the pajamas are soft yet durable, providing the necessary comfort for a good night's sleep.

Fabric Density and Its Impact on Durability

Fabric density is closely related to GSM but focuses on the compactness of the weave rather than the weight. In bamboo pajamas for kids, an optimal fabric density ensures that the garment remains resilient against wear and tear, which is crucial given the active nature of children. High-density fabrics resist pilling and maintain their form even after multiple washes, an essential feature for children's clothing. Engineers and textile experts work meticulously to achieve a harmonious balance between GSM and fabric density, ensuring the final product is both luxurious and robust.

The Role of Industrial Machinery in Bamboo Pajama Production

Producing bamboo fabric at scale necessitates advanced industrial machinery, orchestrating a fine-tuned manufacturing process. The challenge lies in maintaining the natural properties of bamboo while ensuring efficiency and consistency. Modern textile machinery incorporates sophisticated features like automatic tension control, precise cutting mechanisms, and high-speed weaving capabilities. Such machinery allows manufacturers to create bamboo fabric with the desired GSM and density, meeting the expectations of both quality and quantity demanded by markets.

Machinery such as Circular Knitting Machines and computerized Jacquard looms are pivotal in producing the intricate patterns and soft textures that characterize high-end bamboo pajamas. , fabric finishing machines apply essential treatments, ensuring the pajamas are shrink-resistant and colorfast.

| Fabric Type | Pima Cotton |

| Compliance | CPC Certified |

| Customization | OEM |

| Lead Time | 21 Days |

The 'Mystery Box' Phenomenon in Kids' Apparel

In recent years, the 'mystery box' concept has taken the retail world by storm, offering consumers an element of surprise and delight. In the realm of kids' bamboo pajamas, this marketing strategy appeals by providing a curated selection of pajama sets, each distinct in design and color. For businesses, deploying the mystery box model adds a unique layer of scalability to their operations.

From a technical perspective, the machinery involved in organizing these mystery boxes entails accurate sorting and packaging technology. Automated systems enable efficient item selection and packaging, ensuring that each mystery box is consistently curated. With the help of advanced conveyors and sorting machines, businesses can rapidly assemble mystery boxes that align with consumer expectations for variety and exclusivity.

Concluding Thoughts

The production of kids' bamboo pajamas in sizes 2T-5T serves as an exemplar of how textile engineering intersects with modern manufacturing to create products that fulfill the demands of comfort, sustainability, and market appeal. Understanding the intricacies involved in GSM, fabric density, and the relevant industrial machinery provides valuable insight not only to those within the textile industry but also to business entities exploring new avenues in children’s fashion wear. As the mystery box model continues to entice consumers, the fusion of technical innovation and creative marketing will undoubtedly steer the future of sustainable children's apparel.

In this converging narrative of consumer demand, textile science, and industrial proficiency, kids' bamboo pajamas excel as a product designed with precision and care, ready to accompany young ones in the tranquil voyage to slumber.