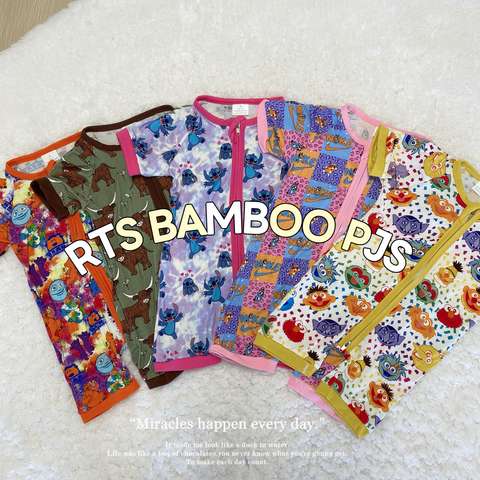

Oekotex 100 Oem For Baby Bamboo Pajamas Shorts

Baby Bamboo Pajamas Shorts: A Guide for B2B Buyers

The Importance of GSM, Fabric Density, and CPSIA Compliance for Baby Bamboo Pajamas Shorts

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | Bespoke |

| MOQ Policy | 300 PCS |

| Lead Time | 38 Days |

When producing baby bamboo pajamas shorts, understanding the technical aspects of fabric density, GSM (grams per square meter), and meeting CPSIA standards is critical. These factors directly influence the comfort, safety, and durability of the product. Industrial machinery and OEM partnerships also play a vital role in maintaining efficient production and high-quality output.

Grams Per Square Meter (GSM) and Its Role in Fabric Selection

GSM is a technical measure of fabric weight and density that determines the feel and performance of the material. For baby bamboo pajamas shorts, maintaining a GSM between 150 and 200 is widely considered optimal. This range balances a soft, breathable feel while retaining durability during frequent washing.

In B2B settings, ensuring a uniform GSM is vital for bulk production. Industrial machinery such as calenders (for enhancing fabric uniformity and smoothness) and precision GSM testing equipment ensures accuracy across large orders. Consistency in GSM enhances the client's trust and minimizes the risk of product returns due to defects.

Fabric Density as a Quality Metric

Fabric density, closely related to GSM, determines the tightness of the weave or knit in the bamboo material. A lower density risks exposing the interior or tearing, while excessively high density may compromise breathability. Bamboo, being a natural fiber derived from the viscose process, benefits from industrial knitting machines that adjust the density parameters automatically.

For baby shorts, consistency in density ensures that the product meets the gentle needs of sensitive baby skin while maintaining strength. Industrially automated knitting systems combined with meticulous OEM quality control measures ensure this balance is achieved efficiently in production at scale.

Technical Advantages of Bamboo Fiber for Baby Clothing

Bamboo fiber provides inherent advantages for baby pajamas shorts, including moisture-wicking properties, natural microbial resistance, and thermal regulation. These attributes come directly from the molecular structure of bamboo viscose fabric. For B2B clients, highlighting the premium characteristics of bamboo in marketing materials helps differentiate their offerings in a competitive market.

Advanced machinery such as rotary screen printers or air-jet looms can be utilized during production to enhance the texture and color consistency of bamboo shorts. Pairing this capability with the correct GSM and density optimizes product quality, making it stand out in consumer segments.

CPSIA Standards: Safety and Compliance

The Consumer Product Safety Improvement Act (CPSIA) outlines strict requirements for children’s clothing, ensuring the safety of materials used. Baby bamboo pajamas shorts must comply with these regulations to meet market approval in the United States.

CPSIA testing involves checks for the absence of harmful chemicals, including lead and phthalates, as well as flammability standards. For fabric-based products, having CPSIA-compliant certifications builds trust with B2B buyers and protects end-users from hazardous exposure.

Steps to Implement CPSIA in Manufacturing

First, raw bamboo viscose suppliers should provide certified, non-toxic materials. Partnering with trusted vendors helps ensure compliance from the material source itself. Second, industrial dyeing processes must use CPSIA-approved, baby-safe dyes, with rigorous testing to avoid contamination.

Finally, conducting third-party laboratory testing on the final product confirms its CPSIA compliance. Accurate testing not only avoids legal risks but also streamlines market entry for baby sleepwear in regulated countries.

Traceability and Labeling for CPSIA Certification

All baby bamboo pajamas shorts must carry clear labeling, including traceability information like batch numbers and manufacturing dates, as part of CPSIA regulations. Leveraging automated label applicators and RFID systems during production ensures error-free labeling at scale. This not only fulfills requirements but also provides logistical advantages for distribution and inventory control.

Working with OEMs: Efficiency and Customization

Partnering with an original equipment manufacturer (OEM) is a strategic move for businesses looking to scale their baby bamboo pajamas shorts production. OEMs bring specialized expertise, streamline production timelines, and offer customized services for branding and packaging.

OEM machinery often includes cutting-edge equipment such as multi-head embroidery stations or automated heat sealing machines, providing a high level of precision in both fabric finishing and decorative elements. These advanced systems reduce manual labor costs and production errors, benefiting B2B buyers in terms of cost control.

Customization Options with OEM Partnerships

An OEM collaboration enables tailored design options, such as custom prints, embroidery, or decorative trims. Buyers can request unique patterns or branding directly from the production floor, ensuring fast turnarounds and exclusivity in the marketplace. Some OEMs also offer specialized packaging solutions, such as eco-friendly kraft paper boxes for bamboo baby shorts, enhancing the product’s appeal.

OEM machinery also supports rapid prototyping, where designs can be tested at minimal cost before large-scale production. This allows buyers to refine their products for the target market without unnecessary delays or expenses.

Industrial Machinery and Its Role in Manufacturing

Manufacturing baby bamboo pajamas shorts requires purpose-built industrial machinery designed to handle the unique properties of bamboo viscose fabric. These machines are optimized for maintaining fabric quality across every stage of production.

Automated weaving and knitting machines ensure uniform fabric texture, while dyeing systems maintain color consistency without compromising bamboo’s natural softness. Investing in this equipment or working with OEMs that utilize state-of-the-art setups ensures a seamless production process.

Quality Control and Inspection Through Automation

Automated fabric inspection machines are vital for catching defects such as uneven patterns, loose threads, or GSM inconsistencies. These systems use high-resolution cameras and sensors to scan finished products before packaging. By identifying flaws early, automated inspection reduces rejects, wastage, and lead times.

Additionally, heat-set machines are often used to strengthen the fibers for enhanced durability, ensuring that the baby bamboo pajamas shorts last longer during use. These steps guarantee high-quality production standards aligned with market expectations.

Scalability with Advanced Production Machinery

Scalability is critical for businesses entering B2B markets. Factories equipped with multipurpose sewing machines, ultrasonic cutting devices, and large finishing units ensure high output levels while maintaining precision. Scalability is particularly important for meeting seasonal demand spikes, such as holiday shopping periods.

Leveraging semi-automated and fully automated systems reduces labor intensive tasks while improving profit margins. High-capacity machinery ensures unit costs remain competitive, giving B2B buyers an advantage in pricing negotiations with retailers.

Why Baby Bamboo Pajamas Shorts Are Ideal for Growing B2B Market Needs

Baby bamboo pajamas shorts are increasingly popular in global markets for their comfort, eco-friendliness, and compliance with stringent safety standards. As businesses aim to deliver premium quality products, understanding the role of GSM, fabric density, and CPSIA-compliance becomes essential. Collaborating with OEM manufacturers ensures scalable, efficient production while incorporating unique product customizations that cater to diverse customer preferences.

Using advanced industrial machinery and adhering to technical best practices ensures long-term success and trust in the competitive market of children’s fashion.