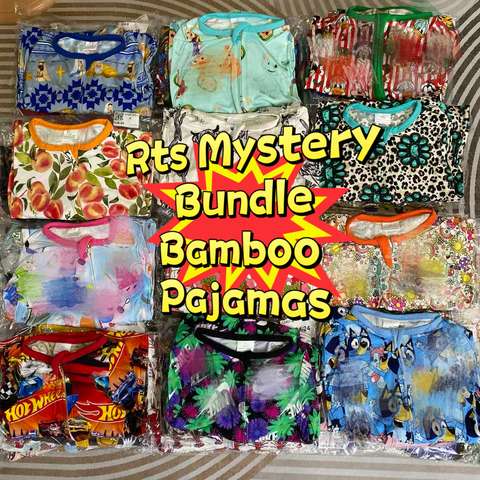

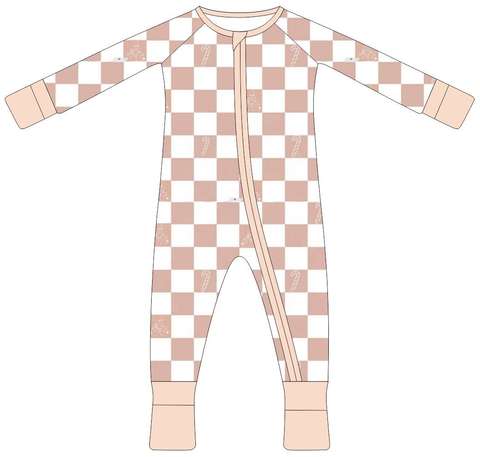

Oem High Quality Factories Custom Solid Color Organic Bamboo Baby Romper Custom Bamboo Spandex Baby Pajamas Mystery Box Odm Factory

The Engineering Behind High-Quality Organic Bamboo Baby Apparel

In the evolving world of textile manufacturing, the demand for sustainable, high-quality baby apparel is on the rise. Leveraging advancements in GSM fabric density optimization and state-of-the-art industrial machinery, manufacturers are redefining standards for infant garments such as bamboo rompers and bamboo spandex pajamas. For businesses purchasing these items in mystery box formats, understanding the engineering and production processes is critical to ensuring quality and sustainability. This piece delves into the technical aspects of producing custom solid color organic bamboo baby rompers and pajamas, focusing on fabric density, material performance, and efficient manufacturing techniques.

Understanding GSM Fabric Density in Bamboo Textiles

When discussing bamboo textiles, GSM (grams per square meter) is a crucial parameter. GSM refers to the weight of the fabric per square meter, influencing not only its durability but also its softness, breathability, and thermal regulation. For infant apparel, these qualities are more than aesthetic; they directly affect an infant's safety and comfort.

Organic bamboo fabric typically falls in the mid-range of GSM, between 180 and 350 GSM, depending on its application. For baby rompers and pajamas, the ideal GSM is around 200 to 300. A lower GSM may result in sheer fabrics unsuitable for robust use, while a GSM exceeding 300 can create overly thick garments that may compromise breathability. Hence, manufacturers aim for an optimal balance to deliver soft yet durable products.

The Role of GSM in Designing Bamboo Baby Apparel

High-quality factories specializing in baby garments ensure precise control over GSM during production. Viscose bamboo fibers, blended with spandex for elasticity, are processed and woven into the desired density. This ensures that:

- Softness: Babies' skin is delicate, requiring ultra-soft fabrics with uniform density to prevent irritation. Organic bamboo naturally achieves this, with GSM adjustments fine-tuning the texture further.

- Sustainability: Bamboo, being a highly renewable resource, is environmentally friendly. Ensuring the appropriate GSM minimizes fabric waste during production.

- Durability: A thoughtfully calibrated GSM protects against tears and extends garment life, making it suitable even for active toddlers.

Factories often utilize industrial GSM testers to validate fabric consistency prior to cutting and stitching. The use of advanced spectroscopic techniques further allows for non-destructive testing of the fabric's uniformity across large volumes.

Industrial Machinery for Precision in Bamboo Apparel Manufacturing

Producing custom organic bamboo baby rompers and spandex pajamas efficiently requires investment in advanced machinery. From spinning to cutting, every stage of production benefits from high-precision industrial equipment designed specifically to handle bamboo fibers and spandex blends.

High-Speed Circular Knitting Machines

High-speed circular knitting machines are central to producing bamboo-spandex fabrics. These machines, equipped with state-of-the-art programming interfaces, ensure seamless knitting while addressing the unique challenges presented by bamboo fibers. Bamboo viscose has a tendency to fibrillate, making it prone to snagging during low-speed production. Hence, advanced machines enable faster yet gentler knitting techniques that preserve the material's integrity.

, programmable machines allow for the creation of both interlock weaves and jersey knits, the two most commonly used patterns in baby rompers and pajamas. Interlock weaving enhances strength and stretch resistance, while jersey knits maintain softness and air permeability.

Computerized Cutting Machines for Customized Designs

Customization plays a major role in the appeal of baby pajamas and rompers, especially for wholesale buyers in the business-to-business (B2B) segment. Modern factories employ computerized laser and die-cutting machines for precision cutting of fabrics. These machines use CAD (Computer-Aided Design) models to execute custom designs specified by clients. Not only does this result in less material wastage, but it also ensures uniformity across large production batches.

For solid color fabrics, dye consistency is another vital factor. Many manufacturers integrate computer-controlled dye vats to achieve uniform coloring. This guarantees that every romper or pajama in the mystery box has matching hues that satisfy stringent quality control standards.

Overlocking and Seam-Stitching Machines

For baby rompers and pajamas, comfort is vital. Seams must be secure yet non-abrasive against delicate skin. Advanced overlocking machines achieve this by producing flat-felled seams that are free of loose threads and sharp edges. These machines are equipped with tension adjustment systems, ensuring proper stitching on spandex-blended bamboo fabrics without breaking or puckering the threads.

High-precision seam-stitching machines also enable features such as snap closures or zipper installations, contributing to the convenience and functionality of the finished product.

Key Quality Features in Mystery Box Bamboo Baby Apparel

B2B customers purchasing custom bamboo baby rompers and pajamas often use the popular mystery box format to acquire diverse selections while enjoying cost efficiency. Several quality checkpoints are integral to ensuring the value of these boxes:

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | Private Label |

| Lead Time | 20 Days |

- Fabric Composition: Industrial machinery like Fourier-transform infrared (FTIR) spectroscopy helps confirm the exact blend of bamboo viscose and spandex, guaranteeing authenticity.

- Color Fastness: Consistency in dye adherence is checked through automated spectrophotometry to prevent color bleeding during washes—critical for babywear.

- Eco-Certifications: Many factories aim for certifications like GOTS (Global Organic Textile Standard) to assure buyers of the sustainability and safety of the materials used.

- Packaging Integrity: Mystery boxes must ensure all garments are packaged hygienically, limiting contamination risks during shipping and handling.

Scaling Customization Through Automation

Meeting the needs of B2B buyers often involves scaling production without compromising customization. Automation has become the linchpin in balancing these priorities. Modern manufacturing setups integrate IoT (Internet of Things) systems, allowing real-time monitoring of each production phase. Early detection of anomalies in weaving, dyeing, or cutting ensures that customer-specific designs are adhered to without delays or rejections.

, AI-powered design platforms help factories forecast demand for specific patterns or colors within mystery boxes. These insights enable manufacturers to preemptively align production quantities with market preferences, reducing excess inventory and optimizing costs for buyers.

The Intersection of Technology and Sustainability in Bamboo Babywear

Custom solid color organic bamboo baby rompers and spandex baby pajamas are more than just apparel—they're a testament to the synergy between innovation and sustainability in textile engineering. By controlling GSM, leveraging industrial machinery, and optimizing large-scale automated processes, manufacturers deliver products that meet stringent quality expectations and eco-friendly standards.

For B2B buyers, sourcing from such high-quality factories ensures a reliable and ethical supply chain. Whether purchased directly or in mystery boxes, these garments are designed to satisfy modern market demands while prioritizing safety, comfort, and sustainability.