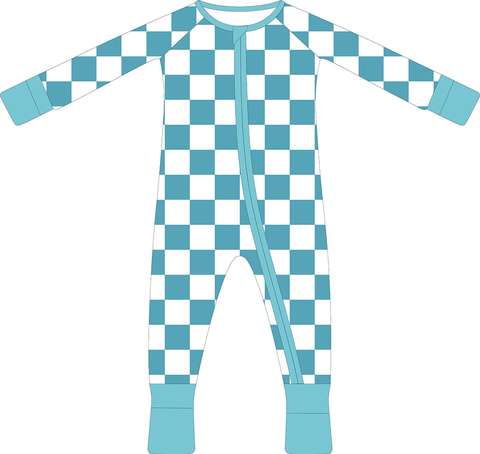

Private Label Bamboo Duck Pajamas Oekotex 100 Wholesale

Bamboo Duck Pajamas: Combining Comfort and Technology

In the rapidly evolving textile industry, bamboo duck pajamas have captivated business-to-business (B2B) retailers due to their unique blend of sustainability and comfort. This article delves into the technical aspects of bamboo fabric, focusing on GSM, fabric density, and the role of industrial machinery in crafting these exquisite garments.

Understanding GSM and its Impact on Fabric Quality

Grams per square meter (GSM) is a critical metric in the textile industry, serving as an indicator of fabric weight. Higher GSM values usually reveal a denser and more durable fabric. For bamboo duck pajamas, a GSM range of 150-200 is often preferred. This range ensures optimum comfort and durability, making these pajamas ideal for year-round use.

Bamboo fabric's unique composition allows for a substantial GSM without compromising softness. The bamboo fibers are lightweight yet strong, producing a fabric that is comfortable and breathable. This GSM range strikes a balance between heaviness for warmth and lightness for breathability, essential for sleepwear like pajamas.

Diving into Fabric Density and Its Role in Wearability

Fabric density, closely associated with GSM, pertains to the tightness of the weave. For bamboo duck pajamas, a medium to high-density weave ensures that the fabric remains soft yet resistant to wear and tear. This density contributes to the fabric’s ability to wick moisture away from the skin, enhancing comfort during sleep.

The comfort provided by the fabric density is complemented by bamboo’s inherent properties. Bamboo is naturally hypoallergenic and antibacterial, making it an ideal choice for individuals with sensitive skin. The tight weave of bamboo duck pajamas not only prolongs garment life but also enhances these natural properties.

Utilizing Industrial Machinery in Manufacturing Bamboo Pajamas

The production of bamboo duck pajamas involves sophisticated industrial machinery to handle the unique properties of bamboo fibers. High-precision machines are essential for maintaining uniformity in GSM and fabric density across batches, ensuring consistent product quality.

### Carding and Spinning Machines

| Fabric Type | Organic Bamboo |

| Compliance | OEKO-TEX 100 |

| Customization | ODM |

| Lead Time | 17 Days |

Initially, bamboo fibers are rendered through carding machines that separate and align the fibers before they proceed to the spinning process. Modern spinning machines, equipped with advanced tension controls, are critical in maintaining the desired thread count and fiber integrity, crucial for the pajamas’ GSM and fabric density.

### Weaving Machinery

The intermediate product is transitioned to weaving machines capable of producing the desired weave pattern and density. These machines are highly automated and can adjust settings rapidly to accommodate any changes in fabric specifications. The precision of these machines ensures consistency, managing the intricate weaving necessary for bamboo duck pajamas.

### Finishing Machines

Finally, finishing machines are utilized to enhance the fabric’s properties, such as softness and shrink resistance. These machines employ various methods, including chemical treatments and mechanical processes, to ensure the permanence of the fabric’s enhancements, thus providing long-term comfort and durability to the consumer.

: Bamboo Duck Pajamas as a B2B Investment

For B2B retailers, investing in bamboo duck pajamas signifies a commitment to sustainable and high-quality products. Understanding the technicalities of GSM, fabric density, and the role of industrial machinery allows businesses to make informed decisions and offer superior sleepwear that meets modern consumer demands.

The intricacies of producing bamboo duck pajamas, from the fabric’s GSM and density to the manufacturing machinery involved, reflect a convergence of nature and technology. These pajamas are more than just a product; they represent advanced textile engineering. For retailers, aligning with manufacturers that prioritize these technical details promises not only better margins but also the promise of satisfied, returning customers.