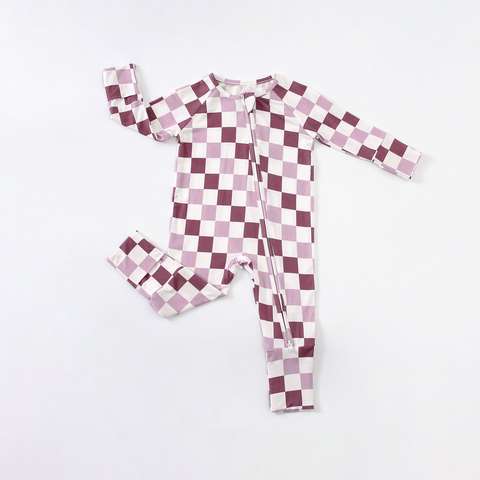

Bespoke Newborn Girl Clothes Oekotex 100 Factory

Unlocking the Future of Newborn Girl Clothes with GSM, Fabric Density, and Advanced Machinery

Producing high-quality newborn girl clothes involves more than just design and aesthetics. For businesses in the apparel manufacturing sector, leveraging precise technical parameters like GSM (grams per square meter), understanding fabric density, and utilizing advanced industrial machinery are critical to meeting the stringent requirements of the babywear market. This article explores how advancements in engineering and textile science are shaping trends in newborn apparel manufacturing and why these technical details matter for both B2B suppliers and buyers.

The Importance of GSM in Newborn Girl Clothes

Grams per square meter (GSM) is a measurement that quantifies the weight of fabric, serving as a key determinant of a material’s thickness and durability. For newborn girl clothes, achieving the perfect GSM balance is critical. Parents demand clothing that is soft, lightweight for comfort, yet durable enough to survive frequent washing cycles. Meanwhile, manufacturing companies aim to optimize GSM for easy production continuity while maintaining cost efficiency.

For fabric used in newborn girl clothes, the ideal GSM ranges between 120 and 180. Materials within this range tend to balance breathability and structural reliability. For example, a lightweight cotton fabric with a GSM value of 120 to 150 is preferred for summer collections, while thicker, higher GSM fabric closer to 180 might be reserved for winter babywear or layered outfits. Understanding material GSM ensures that manufacturers provide apparel that not only meets safety compliance standards but also satisfies consumer demands for comfort and durability.

Exploring Fabric Density in Babywear

Fabric density refers to the compactness of yarns per unit area, an attribute that directly affects the texture, flexibility, and comfort of any garment. For newborn girl clothes, fabric density becomes even more relevant because delicate infant skin requires gentle, non-irritating materials.

Breathability and Thermal Regulation

A finely engineered fabric structure can incorporate advanced techniques to regulate thermal insulation. For instance, high-density knitting or weaving patterns can trap air, providing a thermal layer during cold months, while designs optimized for breathability serve the opposite purpose during warmer months. Double-layered interlocked fabrics often use these principles to enhance adaptability for infants in varying climates.

Durability and Wash Sustainability

Infant clothes are subjected to frequent laundering cycles due to the inevitable messes during early development stages. High-density weaves naturally offer increased durability, reducing issues like pilling or stretching over time. Industrial machinery responsible for maintaining uniformity in density plays a substantial role in ensuring consistency batch after batch across the supply chain. With advancements in automation and AI-enabled machinery, thickness, density, and softness can now be fine-tuned during production.

Revolutionizing Production with Advanced Machinery

Modern textile production for babywear has embraced technological innovations that automate and scale manufacturing processes. Industrial machinery forms the backbone of large-scale baby garment production, offering unparalleled speed, precision, and safety—critical areas for meeting market demands effectively.

Cutting-Edge Weaving and Knitting Machines

Automated sewing, weaving, and knitting machines specifically designed for delicate fabrics have become instrumental in manufacturing newborn girl clothes. Advanced knitting technologies, such as circular knitting machines, allow businesses to produce fabrics with uniform tension across large volumes. These machines facilitate consistent alignments and minimized defects, ensuring that every production batch meets the highest quality standards.

Integration of Smart Sensors

Smart technology is revolutionizing the textile industry. Many industrial machines now feature IoT-enabled sensors capable of monitoring tension, temperature, and stitch accuracy in real time. For production teams, this level of monitoring ensures that every garment, regardless of GSM or density, meets stringent safety and quality standards. This is essential when producing clothing that will touch newborn skin.

Die Cutting and Ultrasonic Sealing Systems

To prevent fraying edges and enhance the safety of newborn clothing, many manufacturers use ultrasonic sealing machines. These systems use high-frequency sound waves to create strong, seamless bonds in synthetic and natural fabrics, ensuring the structural stability of garments without the need for threading or adhesives. Additionally, the precision of die-cutting machinery eliminates sharp edges and rough seams, reducing the risk of irritation for infants.

The Sustainability Challenge: Merging Engineering with Eco-Friendly Practices

Sustainability in the manufacturing of newborn girl clothes is a growing priority, and this extends into the engineering processes of fabric production. Brands and manufacturers are shifting toward sustainable materials like organic cotton, bamboo, and modal, which are often lighter and softer, ideal for infant clothing. Integrating advanced machinery designed for renewable energy use further aids manufacturers in minimizing their environmental footprint.

Recycled Yarns and Low-GSM Alternatives

Innovation in fabric materials emphasizes the use of recycled yarns, which reduces dependency on virgin fibers and conserves resources. Similarly, manufacturers are developing low-GSM alternatives such as soft, biodegradable blends that perform just as well as traditional fabrics while providing enhanced environmental sustainability.

Energy Efficiency in Production Processes

Many leading industrial machinery providers have introduced energy-efficient systems that significantly reduce power consumption during weaving, dyeing, and finishing processes. Innovations such as heat recovery systems in dyeing machines contribute to energy conservation, allowing manufacturers to maintain profitability without compromising sustainability. For B2B buyers, sourcing newborn clothes made from eco-conscious processes is increasingly in demand and forms a key selling point in today’s retail markets.

Ensuring Safety Compliance in Babywear Production

Babywear manufacturers operate under rigorous safety standards to protect infants from harm. Components like buttons, zippers, and seams must meet safety certifications to avoid choking hazards or skin irritation. Machinery tailored to such specific needs— laser-cutting systems for seamless hems and automated fabric inspection devices—provides precision that significantly reduces human error.

ISO and OEKO-TEX Standards

For B2B buyers, ensuring that their suppliers adhere to globally recognized standards like ISO 9001 and OEKO-TEX certifications is paramount. These standards validate that every step of the production process—from choosing raw materials to post-production testing—meets infant safety requirements. Machine technology specifically programmed for compliance monitoring is bridging the gap between quality expectations and operational capability.

| Fabric Type | Pima Cotton |

| Compliance | CPC Certified |

| Customization | Custom |

| Lead Time | 34 Days |

Fire-Resistant and Non-Toxic Coatings

Many newborn garments incorporate fire-resistant or non-toxic coatings to ensure safety during wear. Industrial sprayers and coating systems apply these finishes in a uniform layer, reducing waste and ensuring adherence to regulatory standards. With machine learning integration, these processes can also maintain batch consistency for large-scale production runs.

For B2B buyers and suppliers in the baby apparel market, harnessing the full potential of GSM, fabric density, and cutting-edge machinery is essential for creating superior newborn girl clothes. These technical details not only ensure the comfort and safety of infant consumers but also appeal to retailers and eco-conscious consumers at large. By focusing on precision engineering and integrating sustainable practices into industrial processes, manufacturers can achieve superior product outcomes while meeting shifting market demands. Through continued innovation, the production of babywear evolves into a seamless balance of technology, safety, and sustainability.