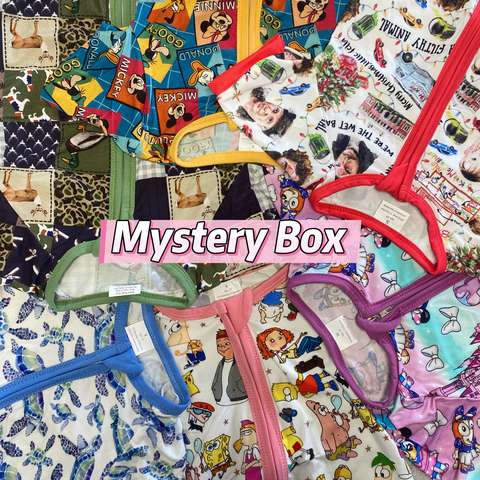

Private Label Mysterious Box Wholesale Popular Style Summer Bamboo Custom Print Two Pieces Children Short Pajama Sets Oem Wholesale

The Rise of Bamboo Fabric in Children's Pajama Sets

Bamboo textiles have gained immense popularity over the last decade due to their sustainable production processes, remarkable softness, and ability to regulate body temperature. When it comes to children’s sleepwear, especially summer pajama sets, bamboo fabric offers unmatched comfort alongside profitability for manufacturers. Wholesale models, such as "mystery box" assortments, add a unique dynamic to the market and are reshaping how suppliers and retailers collaborate.

Focusing on custom-printed two-piece pajama sets for children, this article will delve into the technical aspects manufacturers must consider when crafting these products—specifically fabric density (GSM), machinery optimization, and the intricacies of bamboo textiles for summer wear.

Understanding GSM: Fabric Density for Comfort and Durability

One of the most critical factors for high-quality children’s pajama sets is the fabric density, often measured in GSM (grams per square meter). GSM is a metric that indicates the weight of the fabric over a square meter of material and directly impacts the end product’s performance, affordability, and customer satisfaction. For summer pajamas, the ideal GSM generally ranges from 120 to 160, as this strikes the balance between being lightweight yet durable.

Bamboo fabric typically has a lower GSM compared to cotton, yet its high tensile strength compensates for reduced weight. To create the perfect two-piece pajama set designed for the warmer months, fabric manufacturers work meticulously to ensure the material is breathable without compromising on resilience. A lower GSM within the recommended band ensures the breathable comfort necessary for hot summers, while higher GSM values are suitable for cozy winter wear.

Calculating GSM: Precision and Industrial Relevance

Calculating GSM requires precision, especially for wholesale production where large batches of fabric may be processed. Manufacturers typically use industrial GSM cutters, which take standardized circular samples of fabric. These samples are then weighed, and the weight is converted to GSM using standardized formulas.

This calculation has direct implications for scalability. For example, in a wholesale “mystery box” scenario, consistent GSM across all pieces ensures that end customers receive high-quality products they recognize and trust. Fluctuating GSM can result in mixed reviews and diminished customer retention rates.

Technical Advantages of Eco-Friendly Bamboo in Wholesale Summer Pajama Sets

Bamboo fabric is known for its environmental adaptability. Its cultivation requires fewer resources compared to cotton, making it an eco-friendly choice for manufacturers. Here are some notable properties of bamboo textile relevant to children’s summer pajama sets:

- Moisture-wicking capability: Children often sweat in warmer temperatures, and bamboo’s excellent moisture absorption keeps them comfortable through the night.

- Naturally hypoallergenic: Children’s sensitive skin benefits greatly from bamboo’s antimicrobial and hypoallergenic properties.

- Thermal regulation: Bamboo works to naturally regulate temperature, which is a key selling point for summer sleepwear.

Custom Printing on Bamboo: Challenges and Solutions

Custom prints are a defining feature of modern wholesale offerings, especially for eye-catching children's wear. Printing designs onto bamboo is not without challenges. The inherently smooth texture of bamboo fabrics can pose difficulties for ink adhesion. To address this, manufacturers employ advanced pre-treatment processes, such as enzyme baths or coatings, that open up the fabric’s pores and enhance dye retention.

Additionally, digital printing has significantly advanced in recent years, and machinery like industrial-grade sublimation printers are widely used for this purpose. Sublimation printing provides vibrant, long-lasting results ideal for children’s sleepwear, even after repeated washes.

Machinery Optimization in Large-Scale Production

Machinery plays a pivotal role in crafting children's pajama sets—right from fabric production to cutting, stitching, and finishing. The large-scale nature of wholesale operations requires high levels of automation to meet demand efficiently without compromising quality.

| Fabric Type | Pima Cotton |

| Compliance | OEKO-TEX 100 |

| Customization | ODM |

| Lead Time | 28 Days |

Industrial Machinery Used in Manufacturing Bamboo Pajama Sets

Here’s a breakdown of essential machinery and their relevance to producing mystery box wholesale pajama sets:

- Fabric Knitting Machines: Advanced circular knitting machines are used for creating bamboo fabrics with varying GSM. These machines adapt their needles and gauges to produce fabrics ranging from lightweight to medium-heavyweight.

- Cutting Machines: Laser cutters and die cutters are used to cut fabric with precision. These machines drastically reduce waste material, which is particularly important in eco-conscious manufacturing processes.

- Stitching and Overlocking Machines: High-speed industrial sewing machines, like those used for flatlock stitching, ensure the pajama sets are durable with seamless finishes.

- Printing Machinery: Sublimation printers, as mentioned earlier, achieve detailed custom prints, while screen printers are employed for bulk printing operations where cost efficiency is a priority.

Quality Checks and Sustainability Practices

Quality assurance is vital in ensuring wholesale products meet customer expectations. For bamboo pajama sets, this includes:

- Fabric Testing: Industrial tensile testers evaluate the strength of the bamboo fabric, while pilling testers ensure that the final product retains its appearance after wear.

- Environmental Compliance: Wastewater treatment systems and recycling initiatives are integrated into most modern production plants to meet sustainability targets.

: Engineering Excellence in Wholesale Bamboo Pajama Sets

Crafting summer bamboo custom print two-piece children’s pajama sets is a meticulous process that integrates engineering precision, textile expertise, and cutting-edge machinery. By optimizing GSM, leveraging bamboo's unique properties, and employing high-quality industrial equipment, manufacturers can create products that resonate with eco-conscious customers and deliver unparalleled comfort.

The "mystery box" wholesale model further enhances the appeal of these pajama sets by offering variety and an element of surprise, making it an innovative strategy for brands looking to stand out in the competitive retail space. As the demand for sustainable, custom-designed products grows, investing in high-quality manufacturing processes ensures not only profitability but also customer loyalty for years to come.