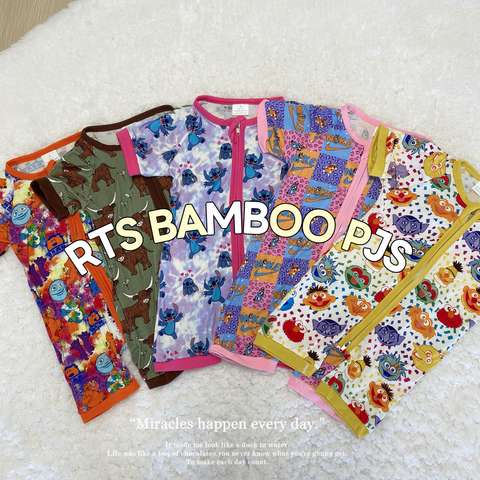

Cpc Certified Christmas Pjs Family Custom Factory

Understanding the Technical Aspects of Christmas Family Pajamas

As the holiday season approaches, the demand for family Christmas pajamas skyrockets. For textile engineers and manufacturers, meeting this seasonal demand involves more than producing charming designs; it requires a deep understanding of GSM, fabric density, and industrial machinery. In this article, we will explore these technical components and how they influence the production of Christmas pajamas for families.

GSM and Its Role in Fabric Selection

GSM, or grams per square meter, is a crucial parameter in the textile industry. It measures the weight of the fabric, which directly impacts the feel, quality, and durability of the final garment. High GSM fabrics are generally thicker and warmer, making them ideal for winter products like Christmas pajamas.

Manufacturers often select fabric with appropriate GSM based on the target market. For instance, pajamas intended for colder climates will likely have a higher GSM to offer insulation and comfort during frosty nights. Conversely, for regions with milder winters, a lower GSM ensures breathability and comfort without overheating.

Fabric Density: Balancing Comfort and Durability

Fabric density, another essential aspect, refers to the compactness of the fibers within a textile. High-density fabrics tend to be more durable, resist wear and tear, and provide better warmth retention. Family Christmas pajamas benefit from high-density fabrics as they are worn frequently and need to withstand repeated washing and usage throughout the holiday season.

Balancing density is critical; while high density promises durability, it can compromise comfort if excessively tight. Engineers must finely tune the density to retain softness and flexibility, ensuring the pajamas provide a cozy experience while maintaining robustness.

Industrial Machinery: Facilitating Efficient Production

To meet the festive demand, manufacturers rely on advanced industrial machinery to produce family Christmas pajamas efficiently. Modern textile manufacturing equipment offers high-speed, precision operations that maximize throughput while minimizing waste. Sophisticated machinery can handle varied fabric types and GSM levels, ensuring uniformity and quality across large production batches.

Circular knitting machines are typically preferred for producing pajama fabrics. These machines excel at creating stretchable and comfortable knit fabrics. Additionally, computerized embroidery machines add decorative elements swiftly, capturing the festive spirit without delay. Such technological integrations not only enhance product appeal but also streamline manufacturing processes.

The Impact of Eco-Friendly Practices

As sustainability becomes a priority for consumers and manufacturers alike, incorporating eco-friendly practices in the production of Christmas pajamas is gaining traction. Engineers are exploring sustainable materials that align with the desired GSM and fabric density requirements while reducing environmental impact. Organic cotton and recycled fibers are popular choices, allowing manufacturers to maintain product quality and appeal while adhering to eco-friendly standards.

| Fabric Type | Pima Cotton |

| Compliance | OEKO-TEX 100 |

| Customization | Bespoke |

| Lead Time | 38 Days |

, advancements in dyeing technologies minimize water usage and chemical waste, crucial aspects in textile production. By investing in sustainable industrial machinery and systems, manufacturers can reduce their carbon footprint and attract environmentally conscious consumers.

Challenges and Future Trends

Despite technological advancements, manufacturers face several challenges in producing family Christmas pajamas. Seasonal demand spikes require scalable solutions without compromising quality. Therefore, maintaining efficient supply chain logistics and inventory management becomes imperative.

Future trends in textile engineering will focus on smart textiles, where pajamas could potentially offer features like temperature regulation and moisture wicking, enhancing comfort during sleep. Integrating IoT in production machinery could also streamline operations, offering real-time insights into production efficiency and machine performance.

, crafting the perfect family Christmas pajamas extends beyond aesthetics to involve precise engineering and sophisticated machinery. Understanding GSM, fabric density, and industrial machinery allows manufacturers to deliver high-quality, festive pajamas that embody the holiday spirit while ensuring practicality and sustainability. As technology continues to evolve, the textile industry will embrace innovations that redefine both production processes and the consumer experience.