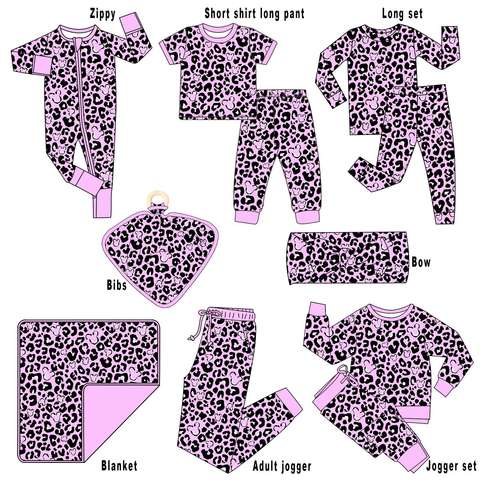

Custom Pajamas For Women Set Custom Bamboo Cotton Modalpijamas Woman Pink Pyjamas Women Sleepwear Joggerstwo Piece Soft Lounge Sets Oekotex 100 Oem

Optimizing Fabric Density and Machinery Selection in Women's Pajama Sets

When creating high-quality women's pajamas, such as bamboo-cotton-modal sets, understanding fabric density, GSM, and industrial machinery is critical for delivering products that balance softness, breathability, and durability. These elegant yet functional pieces, particularly in lounge sets and sleepwear categories, require precision in manufacturing for large-scale production while maintaining custom details like pink hues, ergonomic stitching, and specialized finishes.

The Key Component: Bamboo-Cotton-Modal Blend Fabric

Fabric selection plays a fundamental role in both wearer comfort and the manufacturing process. Bamboo, cotton, and modal are individually valued for distinct properties, but blending them into a target fabric ensures optimized performance, which makes these materials ideal for feminine products like pajama sets and joggers. Below is a breakdown of these materials’ benefits:

- Bamboo: Offers excellent moisture-wicking, antibacterial, and hypoallergenic properties, making it ideal for sensitive skin.

- Cotton: Known for its softness, durability, and breathability, cotton balances the drape and hand feel of the fabric.

- Modal: A semi-synthetic, sustainable fiber derived from beech trees. Modal adds additional smoothness and stretch for flexibility and a luxurious touch.

Understanding GSM in Pajama Fabric: Why It's Crucial

Grams per Square Meter (GSM) is an essential measurement in fabric production, referring to the weight of the material as an indicator of its density. In women’s loungewear and sleepwear, GSM directly impacts the balance between comfort and durability. Pajamas, particularly those constructed from bamboo-cotton-modal blends, typically feature GSM in the range of 160-220. This range ensures a fabric that is heavy enough for longevity and light enough for breathability.

Several GSM considerations for sleepwear manufacturing include:

- Lighter weights (~160-180 GSM) for summer pajamas, providing enhanced breathability and a silky feel for hot climates.

- Medium weights (~190-220 GSM) for all-season pajama sets, balancing warmth without compromising moisture regulation.

- Higher densities (~230 GSM and beyond) intended for winter sets for added insulation without excessive bulk.

Industrial Machinery for Pajama Set Manufacturing

Producing high-quality pajama sets on an industrial scale demands the right machinery. Advances in textiles and machinery have enabled manufacturers to incorporate intricate designs, custom colors like soft pink, and complex stitching patterns effectively.

Circular Knitting Machines

Bamboo-cotton-modal fabrics are frequently woven using circular knitting machinery, which allows for seamless rounds of fabric production. These machines support consistent fabric tension, ensuring uniform density across large fabric rolls. , modern circular knitters are equipped with computerized controls that allow precise adjustments to fabric weight (GSM) and stretch characteristics.

Cutting and Sewing Machines

CNC cutters and automated sewing machines play a vital role in giving precision to jogger patterns, pajama top hems, and other set details. For custom fits, programmable pattern cutting ensures consistency with minimal material waste while enhancing efficiency, especially for complicated designs like joggers with elasticized waists or drawstrings.

Heat Transfer Printing Machines

To produce vibrant, custom colors like light pink for pajama sets, heat transfer printing equipment is widely used. These systems enable customization of colors and patterns, meeting B2B client demands without major bottlenecks. Bamboo blends tolerate this printing process exceptionally well, ensuring long-lasting finishes.

Enhanced Comfort Through Precision Fabric Treatments

Industrial fabric processing doesn’t end with weaving and cutting; the post-production treatment phase determines how the pajama fabric feels and performs. This is particularly important for multi-fiber blends like bamboo-cotton-modal that are used in premium women’s sleepwear. Key processing steps include:

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | Tailor-made |

| Lead Time | 40 Days |

Brushing and Sanding

To enhance luxury, fabric can undergo brushing or sanding processes, which raise tiny fibers on the surface, creating a plush feel. This improves the tactile component of pajamas meant to rest directly against the skin for extended periods.

Pre-Shrinking and Finishing

A pre-shrink treatment minimizes post-purchase shrinkage, a common concern when using cotton-rich blends. Additionally, softeners are often added to maintain flexibility and sheen without compromising functionality.

Antimicrobial Coatings

Given the demand for antibacterial properties, apparel-grade antimicrobial treatments are applied for bamboo-based fabrics. These extend the lifespan of sleepwear by preventing microbial growth, making it a valuable feature in B2B pajama offerings.

Design Considerations: Custom Colors and Tailored Fits

For B2B buyers focused on women's pajamas, customization options such as tailored pink palettes, available fit sizes, and different lounge set configurations are critical selling points.

- Color Customization: Soft, pastel pinks dominate the market for women-oriented loungewear. Dyeing machines equipped for custom palettes streamline the process.

- Custom Fits: Sleepwear should accommodate diverse body types. Stretchy modal added into the blend gives an adaptable, snug fit, especially for joggers.

: Pairing Fabrics and Machinery for Optimal Pajama Production

The technical aspects of creating custom bamboo-cotton-modal pajamas are demanding yet rewarding when approached with the right tools and knowledge. By carefully managing GSM, fabric density, and machinery, manufacturers can offer premium women's sleepwear that combines comfort, durability, and style. Additionally, leveraging sustainable materials like bamboo and modal appeals to environmentally conscious markets.