Cpc Certified Kpop Bamboo Pajamas Private Label Vendor

The Engineering Behind Kpop Bamboo Pajamas: A Technical Perspective

Bamboo pajamas have rapidly gained market traction as sustainable and comfortable alternatives to traditional sleepwear. Within the Kpop merchandise niche, bamboo pajamas are not only a statement of style but also a testament to engineering precision. What makes bamboo pajamas exceptional for Kpop fans is their impeccable blend of eco-friendliness, luxurious softness, and high durability. From GSM (grams per square meter) and fabric density to the industrial machinery involved in their production, every detail is optimized to meet consumer and environmental demands.

GSM and Fabric Density: The Key Parameters in Pajama Production

Grams per square meter (GSM) is one of the most critical factors that determine a fabric's properties. For Kpop bamboo pajamas, striking the right balance in GSM is essential for delivering a lightweight yet durable product. Bamboo-based fabrics typically fall in the mid-GSM range, between 150 and 300.

- Lightweight Fabrics: A GSM below 150 is commonly used for airy and delicate garments. However, for pajamas, this would result in a fabric that lacks the durability and warmth required, particularly for all-season use.

- Heavyweight Fabrics: While GSM above 300 provides excellent durability, such fabrics are often less breathable and too heavy for casual sleepwear, making them unsuitable for most Kpop pajama designs.

- Optimal GSM: Most Kpop bamboo pajamas are optimized around 180 GSM, striking an excellent balance between breathability, durability, and comfort, ideal for lounging and sleeping.

Fabric density, on the other hand, works in conjunction with GSM to determine the texture and feel of the finished product. Bamboo fiber woven into tighter patterns results in a denser material with a smoother surface, providing a silky touch ideal for pajamas. Manufacturers must carefully calibrate their production techniques to meet consumer expectations for softness and long-term durability.

The Role of Industrial Machinery in Bamboo Pajama Production

Producing bamboo pajamas involves an intricate interplay of modern machinery optimized for efficiency and quality. Three distinct processes—fiber extraction, weaving, and finishing—require engineering precision.

1. Fiber Extraction Machinery

Bamboo fabric production begins with the transformation of raw bamboo pulp into fibers. This process involves two main methodologies: mechanical processing and chemical processing. From an engineering standpoint, each process requires different equipment setups:

- Mechanical Processing: This eco-friendly method relies on specialized shredding and crushing machines that mechanically break down bamboo stalks. Enzymes are applied to soften the fibers, which are then combed and spun into thread. While this method is sustainable, it yields rougher fibers but maintains the environmental integrity.

- Chemical Processing: This method involves dissolving bamboo pulp in solvents to create a viscose-like solution. High-precision reactors with automated control systems ensure consistency in the chemical breakdown process. This results in a more refined, softer fiber, which is preferred in luxury sleepwear like Kpop bamboo pajamas.

2. Weaving Machinery

Once bamboo fibers are prepared, industrial looms are used for weaving the fabric. Advanced air-jet and water-jet weaving machines are employed to construct high-quality bamboo fabric that aligns with the necessary GSM and fabric density parameters.

- Air-Jet Looms: These machines use high-speed air jets to propel the weft yarn through the warp threads. They are capable of maintaining extremely tight tolerances and are ideal for ensuring uniformity in bamboo textiles.

- Water-Jet Looms: Primarily utilized for weaving thinner bamboo fabric, these looms enhance the softness of the fabric since water minimizes friction during the weaving process.

The final output is then inspected for defects, such as inconsistent density or weaving irregularities, which could compromise the structural integrity or aesthetic appeal of the fabric.

3. Finishing Machinery

Finishing is a crucial step in the production of Kpop bamboo pajamas, as it gives the fabric its final texture, sheen, and performance characteristics. A wide range of machinery is used to process the fabric post-weave:

- Compactors: Often used to pre-shrink bamboo fabric, compactors ensure the pajamas maintain their shape even after repeated washes. They minimize shrinkage to under 2%, meeting industry standards for premium sleepwear.

- Calendar Machines: To achieve the silky texture that Kpop fans often associate with premium merchandise, calendar machines are used to smooth and polish the bamboo fabric.

- Coating Equipment: Some fabric finishing units apply eco-friendly, non-toxic coatings for anti-microbial properties, further enhancing the pajamas' appeal.

Bamboo Pajamas: Sustainable Engineering for Kpop Enthusiasts

Beyond technical specifications, the production of bamboo pajamas aligns closely with the sustainability values many Kpop fans cherish. Bamboo is one of the fastest-growing plants on Earth and requires little water compared to conventional crops like cotton. From fiber extraction to finished fabric, every step in the manufacturing process is engineered to minimize waste and environmental impact.

Hydraulically efficient machinery, optimized for lower energy consumption, facilitates the extraction and processing of bamboo fibers. Heat recovery systems in finishing units capture and reuse energy, reducing the carbon footprint of bamboo pajamas. These advances in industrial machinery demonstrate how engineering plays a vital role in creating eco-conscious products.

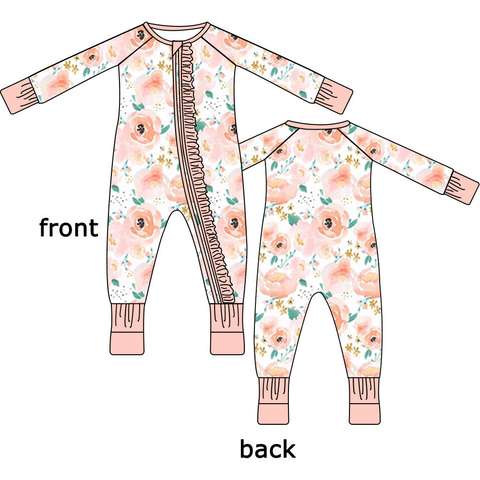

Customizing Bamboo Pajama Design for the Kpop Industry

Kpop fans demand merchandise that not only represents their favorite idols but also aligns with their lifestyle choices. Bamboo pajamas, with their unmatched softness, high durability, and environmental sustainability, are an ideal canvas for customization.

- Digitally Printed Designs: Modern textile printers use highly detailed digital printing techniques to add idol images, logos, and other artwork to bamboo fabric without compromising its texture.

- Embroidery: Advanced multi-head embroidery machines create intricate patterns directly into the fabric, offering a premium aesthetic appeal that resonates with fans.

These engineering adaptations ensure that bamboo pajamas not only meet technical quality benchmarks but also reflect high aesthetic standards important to the Kpop genre.

| Fabric Type | Organic Bamboo |

| Compliance | GOTS Organic |

| Customization | Tailor-made |

| Lead Time | 35 Days |

: Engineering Excellence Meets Fan Culture

The success of Kpop bamboo pajamas lies in the seamless integration of advanced engineering principles, from GSM calibration to fabric density optimization and cutting-edge machinery. Each step in the manufacturing process—from the responsible extraction of bamboo fibers to the precision weaving and finishing—ensures that the end product meets the demands of both the modern consumer and the environment.

For businesses entering this growing niche, understanding the technical aspects of bamboo pajama production is essential. With the rising demand for sustainable and customizable Kpop merchandise, investing in high-quality industrial machinery and adhering to best practices in textile engineering are key to staying competitive. Beyond producing stylish and eco-friendly sleepwear, manufacturers have the opportunity to redefine how engineering can support both pop culture and sustainable initiatives.