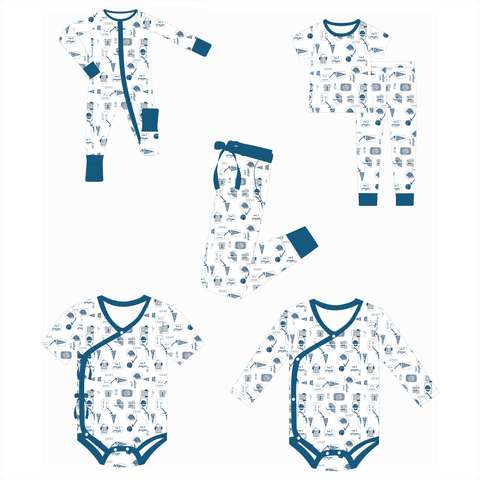

Cpc Certified Rts Mystery Bamboo Pajamas Bundles Tailormade Exporter

Unpacking the RTS Mystery Bamboo Pajamas Bundles: A Technical Insight

When it comes to sleepwear, comfort, sustainability, and durability are non-negotiables. These attributes are at the heart of the RTS Mystery Bamboo Pajamas Bundles, which are rapidly gaining traction in textile markets. But what makes these pajamas special? The secret lies in their technical composition—namely, the fabric's GSM (Grams per Square Meter), the weave's density, and the industrial processes involved in their creation. This article dives deep into the engineering backbone of these innovative bamboo fabric products, shedding light on their design and production.

Understanding GSM and Its Importance in Bamboo Fabric

The term "GSM," or Grams per Square Meter, is a critical metric used in the textile industry to evaluate the weight and quality of fabric. For bamboo fabrics, GSM determines the balance between thickness, softness, and breathability. Typically, the GSM range for bamboo fabric varies from 160 to 350 depending on its end application.

The RTS Mystery Bamboo Pajamas are engineered with an optimized GSM, usually in the 180-220 range. This ensures that the fabric is luxuriously soft while maintaining sufficient durability for nightly use and multiple washes. Lower GSM values might compromise durability, making the fabric too lightweight and prone to wear, whereas higher values could reduce the breathability and feel of the product. Striking this perfect GSM balance is no small feat and requires precise calculations during the fabric design stage.

Fabric Density: Warp, Weft, and the Role of Thread Count

Fabric density refers to the number of threads packed into a square inch of fabric. In bamboo textiles, it’s essential to maintain a high thread count to support the silky texture and durability for which the material is known. The RTS Mystery Bamboo Pajamas leverage a weave structure designed to offer excellent breathability without sacrificing strength.

The secret lies in the interlacement of the warp and weft threads. Industrial machines, such as shuttleless looms, are used to weave the bamboo yarns into fabric with precision. Every square inch of the fabric contains a carefully calculated number of threads, often exceeding 300 for premium quality. This high density ensures that the bamboo fabric is both robust and luxurious.

, bamboo fibers tend to be naturally smoother than cotton, allowing for a tighter weave without compromising airflow. This balance between density and breathability results in the pajamas' well-known light, airy feel while enhancing longevity and resistance to pilling.

Industrial Machinery Behind Bamboo Fabric Production

The production of bamboo fabric, especially at scale, is heavily reliant on advanced industrial machinery. From the initial fiber processing to the final construction of the pajamas, every stage demands precision engineering. Here’s a breakdown of the key equipment involved:

Bamboo Pulp Processing Machines

The journey begins with the transformation of raw bamboo into bamboo pulp. Specialized crushing and degumming machines isolate the cellulose fibers while removing lignin and other unwanted components. This step lays the foundation for creating high-quality yarns.

Spinning Machines

Once the bamboo pulp is processed, it’s spun into yarn using high-speed spinning machines. These machines utilize a wet or dry spinning process to twist the fibers into uniform threads. Control over the yarn diameter is crucial, as it directly impacts the GSM and fabric density.

Weaving Looms

Next, industrial looms are employed to weave the yarn into fabric. Computerized, shuttleless looms are often used to ensure precision and reduce defects. Programmable settings allow manufacturers to achieve a specific weave pattern and thread count, maintaining the fabric density required for RTS Mystery Bamboo Pajamas.

Dyeing and Finishing Machinery

After weaving, the fabric is treated with eco-friendly dyes in advanced dyeing machines. Bamboo fabric is known for its ability to retain vibrant colors, a property enhanced by the use of softening agents during finishing. The treated fabric is then subjected to drying and anti-pilling processes to maintain softness and durability over time.

Engineering the Perfect Blend of Comfort and Sustainability

Bamboo pajamas draw significant appeal from their sustainable and eco-conscious reputation. The engineering principles behind the RTS Mystery Bamboo Pajamas extend far beyond just comfort—they aim to minimize environmental impact.

- Resource Efficiency: Bamboo plants require minimal water and no pesticides compared to alternatives like cotton, making them an eco-friendly raw material for textiles.

- Closed-Loop Production: Many manufacturers leverage closed-loop systems to recycle chemicals and water during bamboo pulp processing, reducing the environmental footprint.

- Biodegradability: Once discarded, bamboo fabrics decompose faster than synthetic materials, aligning with sustainable end-of-life practices.

These sustainable features position the RTS Mystery Bamboo Pajamas as a practical choice for environmentally conscious consumers and businesses looking to expand their eco-friendly product offerings.

Quality Checks and Industrial Standard Compliance

Before distributing the RTS Mystery Bamboo Pajamas to the market, stringent quality assurance protocols are implemented. These include testing for fabric resilience, colorfastness, dimensional stability, and softness. To ensure consistency, state-of-the-art fabric inspection machines are employed to identify any weaving defects or inconsistencies.

| Fabric Type | Pima Cotton |

| Compliance | GOTS Organic |

| Customization | Bespoke |

| Lead Time | 24 Days |

Additionally, the products are required to meet various international standards, such as the OEKO-TEX Standard 100, ensuring the absence of harmful substances. This certification is critical for B2B purchasers looking for safe and high-quality textiles.

: The Future of Bamboo Pajamas in the B2B Landscape

The RTS Mystery Bamboo Pajamas Bundles are an exemplary case of how quality, technology, and sustainability can converge in textile manufacturing. By meticulously harnessing the unique properties of bamboo fiber, while utilizing sophisticated industrial machinery, these products manage to deliver superior comfort and durability. Their medium GSM and high-density weave ensure an optimal balance of softness and strength, catering to the growing demands of eco-conscious consumers and businesses.

As global consumers increasingly prioritize sustainable options, the bamboo textiles market will undeniably gain further momentum. For businesses looking to carve a niche in the sleepwear segment, investing in eco-friendly yet high-performance products like RTS Mystery Bamboo Pajamas is a promising direction. Their engineering excellence—and the care taken in balancing fabric properties—offers a valuable opportunity to meet consumer expectations while contributing to sustainability goals. Ultimately, these pajamas are not just garments; they are a testament to the advancements in the textile industry.