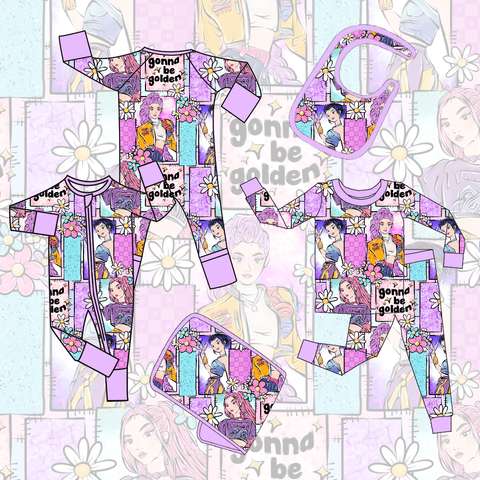

Cpc Certified Whatnot Ready To Ship Bamboo Viscose Baby Pajamas Soft Random Size And Print Baby Zipper Wholesale Blind Box Custom Supplier

Understanding the Unique Features of "Whatnot Ready to Ship Bamboo Viscose Baby Pajamas"

The demand for high-quality baby pajamas is burgeoning as businesses strive to meet consumer expectations. In the competitive world of wholesale fabrics and ready-to-ship garments, "Whatnot Ready to Ship Bamboo Viscose Baby Pajamas" represent a significant innovation. These soft, bamboo-derived viscose baby pajamas, customized with random sizes and prints, are distributed using a blind box wholesale model. This concept leverages industrial machinery and technical efficiencies in GSM regulation and fabric density control. Dive deeper into what makes this product line uniquely appealing for your B2B supply chain needs.

The Fabric Science: Bamboo Viscose and GSM

Bamboo viscose fabric is a transformative material in the baby apparel market, offering unmatched softness and eco-friendliness. This fabric is derived from natural bamboo fibers through a process that converts them into viscose—a semi-synthetic material with fine, breathable properties. It is particularly suitable for baby wear due to its hypoallergenic and moisture-wicking capabilities, which protect delicate infant skin.

One of the core technical specifications of any fabric is its GSM (grams per square meter), which dictates how light or heavy the fabric feels. Bamboo viscose fabrics in baby pajamas typically range between 150 to 220 GSM, ensuring an optimal balance of softness, durability, and thermal comfort. Industrial machinery precisely controls the GSM during production for consistency and quality assurance. This attention to detail enhances the feel of the pajamas while ensuring they stand up to repeated washing and wear.

Fabric Density and Its Role in Durability

Fabric density, another critical parameter, is the measure of how tightly woven or knitted the yarns are. In baby pajamas, proper fabric density is pivotal, especially when dealing with active toddlers and infants. A fabric that is too loosely woven may lead to rapid wear and tear, while an overly dense fabric might compromise comfort.

The bamboo viscose used in these baby pajamas is fashioned using advanced knitting machines that strike the ideal balance between tension and thread count. The end result is a fabric that ensures durability without sacrificing breathability. The density is engineered with baby comfort in mind, providing a snug yet non-restrictive fit.

Industrial Machinery in Wholesale Garment Production

To efficiently produce bamboo viscose baby pajamas at scale, manufacturers rely on state-of-the-art industrial machinery. By automating processes like fabric cutting, stitching, and seam sealing, these machines maintain uniformity and reduce production errors. Let's break down three key machinery types involved in this process:

1. Circular Knitting Machines

Circular knitting machines are a cornerstone of bamboo viscose production for soft, stretchable baby pajamas. These machines produce tubular fabrics with uniform stretchability and elasticity. The precision offered by modern circular knitting machines prevents fabric inconsistencies, ensuring that the pajamas retain their shape even after multiple uses and washes.

2. Automated Sewing Machines

Highly automated sewing machines, outfitted with computerized control systems, play a central role in assembling garments with tight tolerances. They execute complex stitch patterns and intricate seam constructions, making the baby pajamas not only practical but also aesthetically appealing. The incorporation of hidden zippers, an essential part of the product's design, is efficiently performed by these machines.

3. Fabric Inspection Machines

To maintain high quality, fabric inspection machines are employed to scan rolls of bamboo viscose fabric for defects before they are cut for sewing. These machines use advanced sensors to pinpoint inconsistencies like uneven fabric density, tears, or thread irregularities. This ensures that only premium-quality fabric makes it to the final production line.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | Private Label |

| Lead Time | 35 Days |

Why Blind Box Wholesale for Baby Pajamas?

The concept of a "blind box" has gained traction across various industries as a novel and flexible distribution strategy. In this model, businesses receive wholesale shipments that include random sizes and prints of the bamboo viscose baby pajamas. While this might seem unconventional, it offers several strategic advantages for B2B buyers:

Streamlined Inventory Management

The blind box model eliminates the need for precise pre-ordering of sizes and designs, simplifying inventory management for retailers. For B2B buyers, this approach significantly reduces the guesswork and the risk of overstocking any one SKU. Manufacturers leverage demand forecasting algorithms to ensure that shipments include a balanced mix of sizes and designs, optimizing the distribution process.

Cost Efficiency

The fixed pricing structure of a blind box wholesale model allows buyers to access high-quality bamboo viscose baby pajamas without the typical premiums associated with custom orders. The cost efficiency is amplified by bulk production efficiencies facilitated by advanced industrial machinery.

Enhanced Market Appeal

Consumers are increasingly drawn to unique, limited-print designs for baby clothing. The randomness of prints in the blind box model gives retailers an edge in marketing premium yet exclusive product lines. Baby pajama blind boxes are especially appealing to eco-conscious parents, given the sustainable profile of bamboo viscose fabric.

: The Wholesale Opportunity for Bamboo Viscose Baby Pajamas

"Whatnot Ready to Ship Bamboo Viscose Baby Pajamas" embody innovation at the intersection of fabric science, industrial engineering, and modern distribution strategies. For B2B buyers, the combination of eco-friendly material, superior GSM control, and industrial precision offers an unparalleled opportunity to deliver high-quality baby apparel to their markets. The blind box wholesale model further simplifies the supply chain while enhancing consumer appeal.

Whether you are a distributor, retailer, or logistics stakeholder, considering bamboo viscose baby pajamas as a core offering in your lineup is a step towards aligning quality with efficiency. By leveraging advancements in GSM regulation, fabric density optimization, and industrial production methods, your business can meet both economic and environmental objectives.