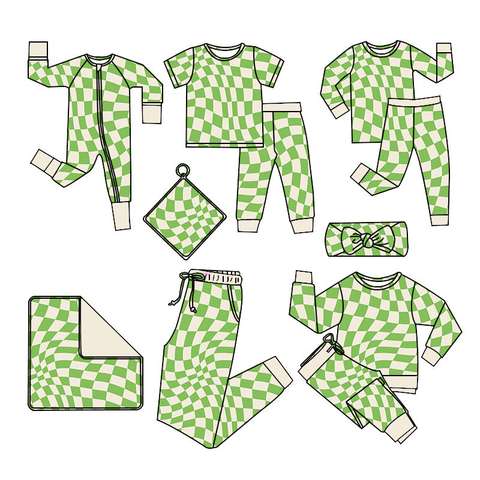

Cpc Certified Wholesale Cute Baby Pajamas Odm Manufacturer

The Intricacies of Wholesale Cute Baby Pajamas: A Technical Perspective

Understanding GSM in Baby Pajama Fabric

GSM, or Grams per Square Meter, is a crucial metric in fabric manufacturing that directly impacts the quality and functionality of baby pajamas. As an engineer focusing on the textile industry, understanding GSM allows manufacturers to tailor their fabric choices to ensure comfort, durability, and cost-effectiveness.

For baby pajamas, a GSM range of 150-200 is optimal. This provides a balance between lightweight and warmth, catering to the sensitive skin of infants while ensuring durability during frequent washes. Higher GSM indicates thicker fabric, which can be useful for cooler climates. Lower GSM, on the other hand, offers breathability for warmer environments.

Fabric Density and Its Role in Quality Control

Fabric density is another critical factor in determining the quality of baby pajamas. It affects not only the feel but also the longevity of the garment. Density is closely related to GSM; however, it focuses more on the weave and composition of the fabric.

High-density fabrics provide better insulation and are less likely to wear thin after multiple washes. For manufacturers targeting longevity and premium quality, selecting fabrics with high density will ensure the pajamas remain soft and intact over time. Conversely, lower density fabrics might reduce costs but at the sacrifice of afterwash integrity.

Industrial Machinery in Pajama Manufacturing

Industrial machinery is at the heart of mass-producing baby pajamas. Automation has advanced significantly, allowing for precise cutting, sewing, and finishing processes that guarantee consistency and efficiency in production.

High-speed sewing machines, computerized embroidery equipment, and automated cutting machines are integral in maintaining the standards required for high-volume orders. Engineers must ensure these machines are calibrated for optimal performance to avoid costly errors in fabric cuts or stitching, which can lead to waste and increased overhead.

The Impact of Technology on Fabric Design and Customization

Today's baby pajama wholesale operations are heavily influenced by technological advancements in fabric design and customization. Digital printing technologies, for instance, have revolutionized how patterns and designs can be applied to fabric on a large scale without compromising quality.

, CAD software enables manufacturers to simulate fabric designs and adjust parameters like color fastness and pattern repetition before production, allowing for rapid prototyping and design iteration. This flexibility is particularly important for bulk orders where client specifications can vary significantly.

Supply Chain Considerations for Wholesale Distribution

The supply chain in the textile industry is complex and involves various stages from raw material acquisition to logistics and distribution. Engineers must consider several factors to optimize this flow, ensuring timely delivery and minimal disruptions.

| Fabric Type | Pima Cotton |

| Compliance | GOTS Organic |

| Customization | Private Label |

| Lead Time | 17 Days |

Effective transportation strategies, vendor management, and inventory control are vital components. Employing ERP systems can streamline these processes, providing real-time tracking and forecasting capabilities. This not only enhances order fulfillment rates but also reduces the likelihood of stockouts or overproduction.

The wholesale market for cute baby pajamas is a technically demanding sector, requiring a thorough understanding of fabric qualities, machinery specifications, and supply chain intricacies. By leveraging precise engineering principles and modern technological tools, manufacturers can deliver products that meet the high standards expected by retailers and end consumers alike. Ensuring the right GSM and fabric density, utilizing advanced machinery, embracing digital design technologies, and optimizing the supply chain are key to achieving success in this competitive market.