Cpsia Compliant Newborn Sleepsuit Odm Exporter

Revolutionizing Newborn Sleepsuits with Precision Engineering and Advanced Fabric Solutions

The newborn sleepsuit has become a cornerstone of infant apparel, combining comfort, safety, and functionality for the most vulnerable segment of humanity. In recent years, advances in industrial machinery, fabric density optimization, and GSM (grams per square meter) measurements have led to groundbreaking innovations in newborn garment manufacturing. This article dives into the engineering and manufacturing processes behind modern sleepsuits, detailing how cutting-edge technology ensures superior quality and functionality in textile production.

The Role of GSM in Newborn Sleepsuit Manufacturing

GSM serves as a critical metric in assessing fabric density, which directly impacts the quality and usability of newborn sleepsuits. GSM is calculated by determining the weight of a square meter of fabric, and it plays a pivotal role in optimizing material thickness, softness, and durability.

For newborn apparel, the ideal GSM typically ranges from 150 to 250 GSM. This range ensures balance between lightweight comfort and protective integrity, crucial for sensitive infant skin. Specialized machinery such as digital GSM meters and industrial-grade fabric analyzers facilitate precise measurement, enabling manufacturers to create garments tailored to specific needs, such as seasonal variations (lighter fabrics for summer and heavier for winter).

Fabric Density: Striking the Balance Between Softness and Durability

Fabric density is another essential attribute that dictates the feel and functionality of newborn sleepsuits. While low-density fabrics may offer enhanced breathability, they sometimes compromise durability, leading to wear and tear under frequent washing cycles. Contrarily, high-density fabrics provide more robustness but can feel overly rigid or heavy.

Innovative engineering solutions have emerged to address this dichotomy. Advanced looms and knitting machines enable manufacturers to produce sleepsuits with medium-density fabrics that maximize softness without sacrificing dependability. Additionally, integrating natural fibers like cotton with synthetic blends like polyester enhances the garment’s flexibility and longevity while meeting strict safety and quality standards.

Industrial Machinery Driving Precision in Newborn Apparel

To achieve the high standards of comfort and quality demanded in newborn sleepsuits, manufacturers rely heavily on state-of-the-art industrial machinery. From spinning and knitting machines to fabric softening systems, every step in the production process benefits from technological advancements.

Automated Spinning for Fiber Consistency

The journey from raw fiber to fabric begins with automated spinning systems capable of maintaining uniform consistency across batches. These machines combine computer-controlled monitoring systems and high-precision rollers, ensuring threads maintain their tensile strength and uniformity. This consistency is essential for producing sleepsuits with smooth, irritation-free textures suitable for newborn skin.

Jacquard Knitting Machines for Enhanced Design Capabilities

Knitting machinery, particularly Jacquard systems, plays a crucial role in creating patterned fabrics with impeccable precision. Using these machines, manufacturers can introduce varied textures and designs while retaining the fabric’s softness and stretchability. This feature allows for customized sleepsuits tailored to branding preferences or special-request designs, all without compromising comfort.

Quality Control with Fabric Density Analyzers

Quality control is paramount in newborn sleepsuit manufacturing. State-of-the-art fabric density analyzers equipped with laser technology or ultrasonic measurements ensure the material adheres to target specifications. Machines like these maintain a microscopic level of accuracy, identifying discrepancies during the production process before they escalate into manufacturing defects.

Innovative Fabric Treatments for Enhanced Comfort

Beyond machinery and engineering principles, modern treatments have further revolutionized the production of newborn sleepsuits. Techniques such as enzyme washing, pre-shrinking, and anti-microbial coating serve as examples of innovative approaches to fabric improvement.

Enzyme Washing for Softness

Enzyme washing, a biotechnological treatment process, helps improve the softness of sleepsuits by breaking down excess fibers and impurities in the fabric. This treatment not only enhances the feel of the material but also prolongs its lifespan, accommodating the rigorous washing cycles characteristic of newborn apparel.

Pre-Shrinking: Reducing Post-Purchase Issues

Pre-shrinking is employed to stabilize the fabric before it reaches the consumer. This step eliminates the risk of unexpected size changes after laundering, ensuring parents receive durable, reliable sleepsuits for their infants. Industrial pre-shrinking machines utilize heat and pressure treatment to set the fabric’s final dimensions, a process that combines efficiency with precision.

Anti-Microbial Coatings for Hygiene

In the realm of infant clothing, hygiene is non-negotiable. Anti-microbial treatments on newborn sleepsuits ensure bacterial growth is minimized. Commonly applied using spray-coating equipment or dip-coating baths, this feature gives parents peace of mind regarding their child’s safety while further enhancing the fabric's durability.

Sustainability in Newborn Sleepsuit Engineering

The engineering of newborn sleepsuits is increasingly focused on minimizing environmental impact while maintaining high-quality standards. With growing awareness about the ecological footprint of textile production, manufacturers are implementing sustainable solutions across all phases of the process.

Eco-Friendly Fibers

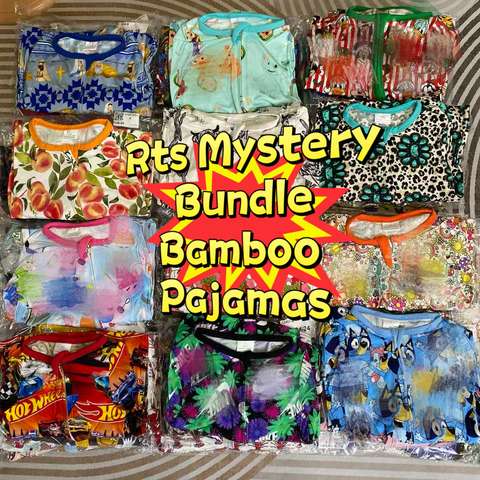

Bamboo and organic cotton fibers are becoming widely adopted in newborn garment production due to their biodegradability and renewable nature. These fibers are processed using advanced spinning and knitting machinery designed to minimize waste and reduce energy consumption. By combining synthetic innovations like recycled polyester, manufacturers can craft eco-conscious blends that align with modern sustainability goals.

| Fabric Type | Organic Bamboo |

| Compliance | GOTS Organic |

| Customization | Private Label |

| Lead Time | 25 Days |

Energy-Efficient Machinery

The latest industrial machines are tailored to reduce power consumption, incorporating features like variable frequency drives (VFDs) and energy monitoring systems. Such upgrades not only lower overhead costs but also minimize carbon emissions, allowing manufacturers to offer eco-friendly products without compromising operational efficiency.

Water Conservation and Recycling

Sleepsuit manufacturing frequently involves processes such as dyeing and enzyme washing that consume significant amounts of water. By integrating advanced water recycling units, manufacturers have been able to drastically reduce water use and limit wastage. These systems also filter and purify water, ensuring that wastewater expelled during production adheres to environmental regulations.

: Engineering the Perfect Sleepsuit

The engineering and manufacturing of newborn sleepsuits have reached new levels of sophistication, driven by innovations in GSM measurement, fabric density optimization, and state-of-the-art industrial machinery. With enhanced comfort, durability, hygiene, and sustainability in focus, the industry continues to evolve, shaping the future of infant apparel.

By utilizing automated systems, precision machinery, advanced fabric treatments, and eco-friendly solutions, B2B textile manufacturers are unlocking new possibilities in a competitive market. The newborn sleepsuit has grown beyond being a simple garment—it is now an embodiment of engineering prowess and technological ingenuity. As these developments continue, businesses remain at the forefront of delivering high-quality, sustainable products to meet the unique needs of infant care.