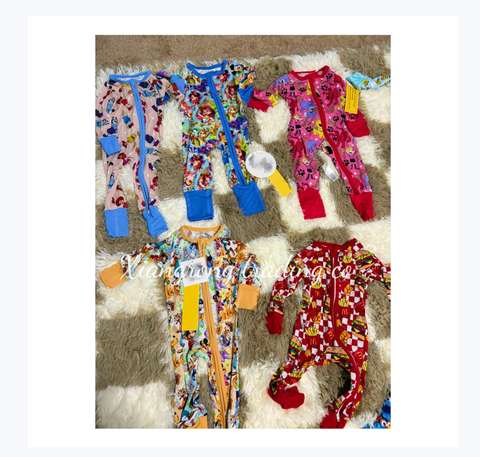

Astm F963 Bamboo Fiber Pajamas Cpsia Compliant Oem

The Rise of Bamboo Fiber Pajamas in Modern Textile Manufacturing

Bamboo fiber pajamas are becoming a flagship product in the textile industry, offering sustainability, functionality, and luxury in one package. Companies involved in fabric production and garment manufacturing are increasingly turning to bamboo fibers for their unique characteristics, including softness, breathability, and eco-friendliness. For B2B players, understanding the key technical aspects—such as GSM (grams per square meter), fabric density, and the role of advanced industrial machinery—is critical to staying competitive in this growing market.

Understanding GSM and Fabric Density in Bamboo Fiber Pajamas

The quality, feel, and durability of bamboo fiber pajamas heavily depend on two parameters: GSM and fabric density. These two terms are pivotal for textile engineers looking to balance comfort, functionality, and production efficiency.

What is GSM and Why Does It Matter?

GSM, or grams per square meter, is a measure of fabric weight that directly affects the thickness, durability, and comfort of a material. In bamboo fiber pajamas, GSM usually falls between 150 and 300, the sweet spot for ensuring breathability and softness without compromising on durability. Lower GSM fabrics (150-180) are lightweight, suitable for warmer climates, while higher GSM fabrics (250-300) are thicker, providing added warmth for colder conditions.

B2B manufacturers should collaborate closely with textile engineers to optimize GSM values based on intended consumer markets and seasons. Analyzing regional climatic conditions and purchasing patterns can help determine the ideal GSM and minimize wastage during production.

The Role of Fabric Density in Durability and Comfort

Fabric density complements GSM by determining how tightly the yarns are packed. While GSM measures weight, fabric density studies the structural arrangement of the fibers, making it equally essential for product engineering. In bamboo fiber manufacturing, tighter weaves ensure durability, while looser weaves enhance breathability. A proper balance between these extremes is paramount for high-performance pajamas. For instance, densified fabrics are favorable for sports and loungewear markets demanding longevity under repeated washing cycles.

Fabric density is largely influenced by industrial machinery. Advanced textile manufacturing equipment capable of micrometer-level precision is needed to maintain consistent density patterns across batches, highlighting the intersection of engineering and fabric design.

Industrial Machinery for Bamboo Fiber Pajama Production

The production of bamboo fiber pajamas requires specialized machinery that can process delicate bamboo fibers without compromising their structural integrity or softness. Additionally, the machinery must comply with the stringent requirements of modern sustainability protocols. Below, we delve into the three main stages where industrial machinery plays a pivotal role: fiber extraction, yarn spinning, and textile knitting/weaving.

Fiber Extraction and Preprocessing

The first step in creating bamboo fiber pajamas involves transforming hard bamboo stalks into soft, spinnable fibers. This process requires specialized decortication equipment to strip the raw material. Modern machinery employs a combination of mechanical and enzymatic treatments to process bamboo efficiently while avoiding harmful chemicals often associated with viscose production.

Innovations in equipment, such as closed-loop chemical recycling systems, are gaining traction for their ability to repurpose organic solvents used in the bamboo fiber extraction process. These systems not only reduce environmental footprint but also cut operational costs for manufacturers by minimizing waste.

Yarn Spinning: Precision Matters

Once preprocessed bamboo fibers are extracted, they undergo spinning to convert them into yarns. This step often employs ring spinning or open-end spinning machinery, depending on the desired thread count and quality. Ring spinning provides finer and smoother yarns suitable for premium pajamas, while open-end spinning offers cost efficiencies for mass-market production.

Advances in spinning machinery, such as real-time monitoring and digital control systems, enable manufacturers to achieve higher consistency, minimize defects, and predict breakdowns. B2B textile manufacturers investing in Industry 4.0-ready machinery can gain a competitive edge by integrating these automated systems into their spinning lines.

Knitting or Weaving Bamboo Fabrics

The final stage in fabric production involves converting bamboo yarns into fabrics through knitting or weaving. Each method has specific applications: weaving typically results in stronger textiles, while knitting offers stretchability and softness, ideal for pajamas. Advanced circular knitting machines are widely used for bamboo pajamas due to their ability to produce seamless, fine-gauge fabrics with a luxurious finish.

High-speed knitting machinery with programmable patterns enables greater flexibility in customization, allowing manufacturers to cater to diverse consumer preferences with minimal downtime during product transitions.

| Fabric Type | Organic Bamboo |

| Compliance | CPSIA Compliant |

| Customization | Private Label |

| Lead Time | 27 Days |

Sustainability Innovations in Bamboo Textile Machinery

As consumer demand for sustainable fashion rises, B2B players in the bamboo fiber pajama market must embrace green manufacturing practices. Innovations in industrial machinery have made it increasingly possible to produce environmentally friendly textiles at a competitive scale.

Water- and Energy-Efficient Systems

Triboelectric spinning and low-energy dyeing units are transforming bamboo fabric production by significantly reducing energy consumption and wastewater generation. Machinery with integrated heat recovery systems can further minimize operational costs by reusing energy from earlier production stages.

For manufacturers targeting eco-conscious brands, investment in such machinery can act as a strong unique selling proposition (USP) that differentiates their products in the B2B market.

Recycling Waste at Scale

Textile machinery manufacturers are also innovating around waste management. Bamboo fiber production yields a significant amount of by-products, which can now be repurposed using compact recycling units. Waste fibers can be blended back with virgin materials, resulting in cost-effective bamboo textiles with minimal environmental footprint.

The Importance of Quality Control in Bamboo Textile Production

Bamboo fiber pajamas require stringent quality control, which is now made possible through advanced machinery equipped with sensors and data analytics. Near-infrared spectroscopy (NIRS) tools, for example, offer real-time on-line analysis of moisture content and fiber elasticity, ensuring consistent product quality across production lines.

Smart factories utilizing IoT-enabled machinery can monitor fiber processing parameters such as tension, dye absorption, and thread uniformity. These insights allow engineers to make proactive adjustments, minimizing defects and downtime in the production process.

: The Future of Bamboo Fiber Pajamas in B2B Markets

Bamboo fiber pajamas, once a niche product, are steadily becoming a core offering in sustainable fashion. For B2B manufacturers, the technical parameters of GSM, fabric density, and machinery precision are essential considerations for creating high-quality bamboo garments that resonate with consumer demands. By embracing advancements in eco-friendly industrial machinery and cutting-edge textile technology, businesses can not only enhance their production efficiency but also drive innovation in a competitive market. The transition to smart, sustainable manufacturing methods will undoubtedly be the next big step for players in the bamboo textile industry, paving the way for scalable, ethical production strategies.

By staying ahead in these developments, manufacturers and suppliers can meet the growing global demand for premium, eco-conscious pajamas while securing their place as leaders in textile innovation.