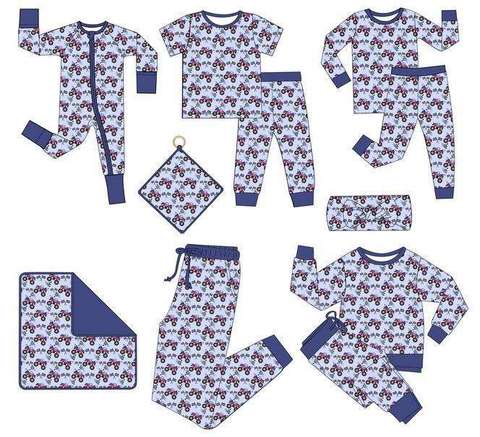

Cpsia Compliant Random Mix Bamboo Wholesale Baby Pajamas Gots Organic Vendor

Exploring Bamboo Wholesale Baby Pajamas: Quality, GSM, and Machinery

Bamboo fabric has emerged as a highly sought-after material in the textile industry due to its softness, sustainability, and performance. Wholesale production of baby pajamas from bamboo requires deliberate attention to fabric properties like GSM (gram per square meter), fabric density, and the industrial machinery employed. For businesses exploring bamboo baby pajamas in bulk, understanding these technical aspects is pivotal for achieving product excellence and capitalizing on market demand.

The Role of GSM in Bamboo Baby Pajamas

The term GSM (gram per square meter) defines the weight of the fabric and is a crucial factor when designing garments for infants. For bamboo baby pajamas, the GSM must strike a balance between comfort and durability. Lightweight fabrics below 150 GSM tend to offer exceptional softness but might lack resilience. Conversely, fabric weights exceeding 250 GSM provide durability but could compromise breathability, which is critical for infant clothing.

Ideally, bamboo baby pajamas fall within the range of 180–220 GSM. At this range, the fabric remains soft and breathable, perfect for delicate baby skin, while also offering resistance to wear and tear. When sourcing wholesale bamboo fabrics, businesses should ensure producers adhere to this GSM range for optimal performance, especially since bamboo textiles inherently provide antibacterial properties and moisture-wicking capabilities that enhance user comfort.

Fabric Density: A Matter of Quality and Functionality

Fabric density complements GSM in determining the feel and functionality of apparel. While GSM quantifies weight, density measures how tightly yarns are packed within the fabric. In bamboo baby pajamas, density requirements depend on the weave or knit style used during production. A proper density ensures durability while maintaining the stretch and softness required for infant clothing.

Bamboo textiles are often manufactured using knit techniques such as jersey or interlock since these provide exceptional stretch and comfort. For baby pajamas, an average fabric density ranging from 20 to 40 stitches per inch (SPI) works well for jersey knits. Interlock knits, known for their superior durability, can use slightly tighter densities, enhancing the longevity of the product.

Fabric density impacts the following aspects of production:

- Shrinkage: Denser fabrics, when treated correctly during pre-production, experience reduced shrinkage during washing.

- Fit: Proper density ensures baby pajamas retain their shape after repeated use and washing.

- Comfort: An optimally dense fabric avoids stiffness, ensuring softness for baby garments.

When dealing with wholesale bamboo textile suppliers, businesses should verify testing standards for density consistency, as minor deviations can significantly affect quality during scaling production.

Optimizing Industrial Machinery for Bamboo Textiles

The production of bamboo baby pajamas requires advanced industrial machinery capable of handling delicate fibers while delivering scalable output. Bamboo fibers, while durable, require specific treatments during knitting, cutting, and sewing to prevent damage and ensure uniformity. This makes the choice of machinery integral to wholesale operations.

Textile Knitting Machines

For bamboo knitting, circular knitting machines designed for fine natural fibers are recommended. These machines produce consistent stitch patterns while managing stretch, which is crucial for baby clothing. High-speed models with computerized controls optimize bamboo fabric knitting by adjusting tension and stitch size dynamically, reducing defects.

Cutting and Sewing Machinery

Precision cutting machines equipped with laser technology ensure minimal waste during the bamboo fabric cutting phase. Bamboo textiles, when cut improperly, may fray or lose their shape over time, so accuracy during this process is non-negotiable. Additionally, sewing machines tailored for knit fabrics, such as those with serger capabilities, play a critical role. Flatlock stitches, commonly used for baby pajamas, ensure smooth seams that minimize irritation for sensitive skin.

Pre-Treatment and Dyeing Equipment

Pre-treatment and dyeing units handle the unique properties of bamboo fibers. Bamboo's natural antimicrobial qualities resist conventional dye absorption, necessitating machinery with advanced water-soluble dye application systems. Continuous open-width processing lines with low liquor ratio technologies are ideal for maintaining bamboo's softness while ensuring vibrant, long-lasting colors. This equipment is particularly vital when producing wholesale bamboo baby pajamas designed in various patterns or hues.

Quality Assurance in Random Mix Bamboo Baby Pajamas

Stocking and delivering random mix bamboo baby pajamas requires rigorous quality assurance protocols at every production step. Random mixes often involve various sizes, patterns, and colors to appeal to diverse customer demands and age groups. Maintaining uniformity amid this variety depends on stringent testing mechanisms.

Fabric Testing

GSM and density testing must adhere to industry standards like ASTM D3776 and ASTM D8007 to validate consistent weight and density. Wholesale suppliers should also utilize advanced spectrophotometers to ensure fabric colors meet pre-specified Pantone or RAL values, as consistent coloration is a determinant for customer approval.

Seam and Thread Strength Evaluation

Baby pajamas undergo frequent washing, so seams and threads must endure mechanical stress over time. Specialized seam durability tests such as ASTM D6193 ensure pajama seams can handle repeated laundering without unraveling or damaging the garment structure.

Packaging Inspection

Random mix bamboo wholesale baby pajamas often arrive in assorted designs in a single shipment. Suppliers must implement control procedures to verify assortment accuracy, packaging integrity, and compliance with labeling requirements. Automated package inspection machinery can streamline this process, ensuring businesses provide accurate orders to their clients.

Sustainability and Market Trends

Bamboo textiles align with growing consumer demand for sustainable and eco-friendly apparel, presenting unique opportunities in the wholesale baby pajama sector. Bamboo cultivation requires minimal water and no pesticides, making it more environmentally advantageous than cotton or synthetic fibers. By leveraging these sustainable properties, businesses can tap into an eco-conscious customer base while reducing their carbon footprint.

Leveraging Bamboo’s Antibacterial Properties

Baby pajamas made from bamboo naturally resist bacterial growth, providing a hygienic choice for delicate skin. As parents increasingly prioritize health-oriented clothing for infants, wholesale businesses can market bamboo apparel as both sustainable and safe. Highlighting certifications like OEKO-TEX or USDA Organic further enhances a product’s market appeal.

Transparency in Supply Chain Management

In wholesale operations, transparency often becomes a deciding factor for buyers. Demonstrating ethical sourcing practices, including certifications for bamboo material harvesting and fair working conditions at production facilities, can solidify trust and attract volume buyers who prioritize traceability.

Customization for Buyer Needs

Random mix bamboo baby pajamas allow wholesalers to cater to varied preferences across markets. Machine customization options for patterns, styles, and GSM can help businesses create tailored solutions for buyers. Apart from improving customer satisfaction, this customization builds repeat business and long-term partnerships.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | ODM |

| Lead Time | 29 Days |

Driving Growth in Bamboo Wholesale Baby Pajamas

Investing in the production of bamboo wholesale baby pajamas is an opportunity for businesses to align technical innovation and sustainability with market demands. By leveraging optimal GSM and fabric density specifications and equipping factories with advanced machinery, manufacturers can deliver high-quality products reliably and at scale.

Partnering with reputable suppliers and ensuring rigorous QA protocols further strengthens market appeal. As bamboo continues to gain traction due to its unique properties, wholesale companies have the chance to become early adopters, capturing market share and building partnerships in this growth-oriented sector.