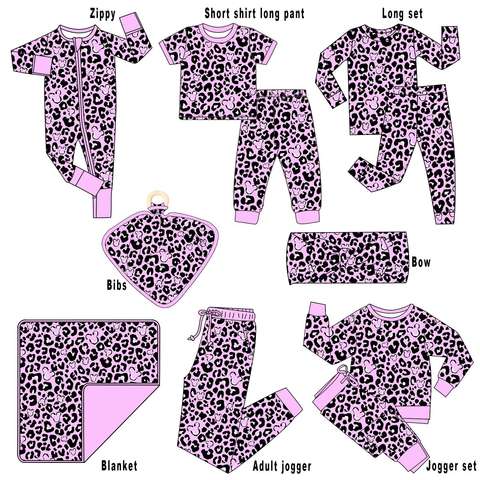

Custom Mystery Box Of Bamboo Pjs Bespoke Oem

The Mystery Box of Bamboo Pajamas: Unlocking Comfort and Sustainability

In the world of textile engineering and industrial manufacturing, sustainable innovations are reshaping product development. Among the new entrants in this space, bamboo pajamas have emerged as a trendsetter, blending luxury, climate-conscious materials, and high-performance fabric engineering. In the context of fabric density, GSM (grams per square meter), and industrial machinery, this 'mystery box' of bamboo pajamas merits a closer technical look at how it transforms the sleepwear market.

Understanding GSM in Bamboo Pajamas

In textile engineering, GSM (grams per square meter) is a key measure of fabric density and weight. It directly impacts the feel, durability, and performance of the garment. For bamboo pajamas, GSM values typically range from 150 to 220, balancing softness, breathability, and structural integrity. The specific GSM chosen can denote whether the pajamas are targeted for summer (lighter weight) or winter (more robust and insulating characteristics).

Low GSM bamboo fabrics (150–160 GSM) are preferred for lightweight and airy summer pajamas because they prioritize breathability and moisture absorption. On the other hand, medium to high GSM fabrics (180–220 GSM) offer enhanced durability, suitable for colder climates where thermal insulation is critical. Engineers calibrate fabric density to ensure the pajamas offer optimum drape while retaining strength. Choosing the right balance between comfort and functionality is an intricate science requiring precise control during every phase of production.

Fabric Density and Bamboo Fiber Properties

The unique properties of bamboo fibers directly influence the fabric density achievable during production. Bamboo is inherently softer than cotton due to its rounded fiber structure, which lacks the abrasive surface texture found in traditional cellulose fibers. Its high moisture-wicking capability – absorbing up to three times its weight in water – makes it an ideal choice for sleepwear.

When processing bamboo into textiles, manufacturers consider both the physical and chemical treatments required to create the fabric. For pajamas, the yarn spinning phase and loom settings play critical roles in defining fabric density. Engineers work towards achieving a uniform weave, avoiding fault lines or uneven distribution of fibers that could compromise the GSM rating or user comfort.

Bamboo-derived textiles also benefit from natural temperature regulation, an aspect that further ties into its fabric density. The micro-gaps within the bamboo fibers regulate airflow, ensuring the fabric remains breathable while retaining a consistent density. This contributes to maintaining a stable GSM measurement, which translates into a tactile, high-end finish.

Industrial Machinery and the Production of Bamboo Fabric

The production of bamboo pajamas relies heavily on advancements in industrial machinery, particularly in spinning, weaving, and finishing processes. Modern high-speed spinning machines combine precision and efficiency in converting bamboo pulp into fine yarns. The uniformity of these yarns ensures a consistent GSM across the fabric, avoiding variations that can lead to inconsistent product quality.

- Spinning Systems: Open-end spinning and ring spinning are the two most common methods used to produce bamboo yarn. Open-end spinning provides faster production rates but may result in coarser fabrics due to less fiber alignment. Conversely, ring spinning delivers a finer and stronger yarn, suitable for premium bamboo pajamas.

- Weaving Machinery: Automatic air-jet and rapier looms are used to weave bamboo fibers into fabric sheets. These looms handle fine yarns effectively, ensuring minimal fiber breakage. The result is a tightly controlled fabric density and smooth finish.

- Finishing Technology: After weaving, the fabric undergoes finishing processes such as mercerization, which enhances luster and dye absorption. Heat-settings and specialized calendaring machines further refine the texture and GSM uniformity of the bamboo fabric.

Automated production lines equipped with industrial sensors maintain tight tolerances for GSM. Integrated IoT systems in machinery continuously monitor the quality parameters, ensuring the material adheres to the desired weight and thickness specifications without compromise.

Sustainability and the Bamboo Revolution in Textiles

Beyond their functional benefits, bamboo pajamas carry significant environmental advantages. Bamboo is fast-growing, renewable, and requires minimal water compared to conventional crops like cotton. From an engineering perspective, this constitutes a sustainable raw material with low ecological impact.

Advanced machinery designed for bamboo processing utilizes closed-loop systems to reduce chemical waste and energy consumption. Engineers and manufacturers are implementing more eco-friendly solvent systems to produce bamboo-based viscose, further minimizing the environmental footprint of bamboo textiles.

Bamboo textiles also lend themselves to recyclability and biodegradability, completing the lifecycle. Unlike synthetic fabrics, which accumulate in landfills, bamboo pajamas decompose naturally, offering a cradle-to-grave product design rooted in sustainability.

The Manufacturing and B2B Implications

For businesses operating in the textile supply chain, bamboo pajamas are a gateway to accessing premium sleepwear markets while maintaining environmental stewardship. Understanding the interplay of GSM, fabric density, and industrial production technology is critical to delivering superior-quality products to B2B clients seeking scalable and profitable partnerships.

By capitalizing on the potential of bamboo fibers, manufacturers can cater to businesses looking to differentiate themselves in competitive markets. The focus shifts from ordinary fabric options to smart, sustainable solutions engineered through innovation and precision.

| Fabric Type | Pima Cotton |

| Compliance | ASTM F963 |

| Customization | Bespoke |

| Lead Time | 40 Days |