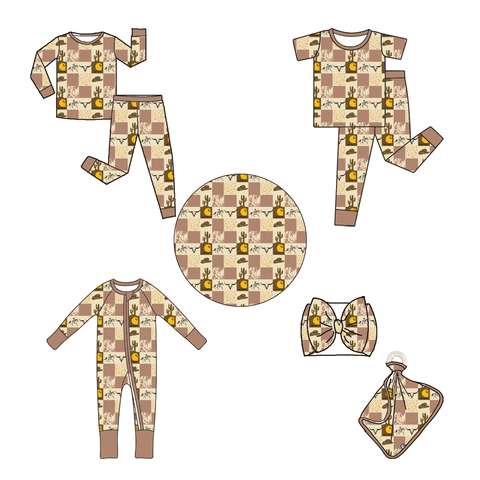

Gots Organic Organic Bamboo Baby Clothes Cpc Certified Oem

Organic Bamboo Baby Clothes: A Technical Insight into Sustainable Fabric and Industrial Processing

As sustainability gains traction across industries, the apparel sector faces increasing scrutiny about its environmental footprint. Organic bamboo baby clothes are becoming a popular solution, blending eco-consciousness with engineering precision. This article delves into the technical aspects of bamboo fabric, focusing on GSM (grams per square meter), fabric density, and the industrial machinery involved in manufacturing garments designed for infants.

The Role of GSM in Bamboo Textiles

The GSM, short for grams per square meter, is a critical metric in evaluating fabric quality and application. For baby clothes, the GSM indicates the balance between softness, thickness, and breathability. Organic bamboo fabrics typically fall within the range of 120 to 200 GSM.

Bamboo fabric with a GSM of 120–150 is lightweight and ideal for swaddles, wraps, and summer garments. The lower GSM ensures optimal breathability and softness, which is crucial for infant comfort. However, fabrics with higher GSM, around 180–200, provide more durability, insulation, and a plush feel. These are perfect for winter clothing or layered baby garments. Engineering these fabrics requires precision to maintain structural integrity while achieving the desired bulk and softness for infant-specific use.

GSM is directly tied to fabric density. Lower densities are more porous and allow airflow, ensuring that baby skin remains cool and free of irritation. Higher densities, while warmer, pose the risk of reduced breathability if not engineered correctly. Manufacturers must carefully balance GSM to meet the needs of various climate conditions while addressing concerns about diaper rash and baby skin sensitivity.

Fabric Density and Its Impact on Comfort

Fabric density plays a pivotal role in determining the thermal performance and tactile quality of bamboo baby clothes. Bamboo fibers inherently have microporous structures, offering natural breathability and moisture-wicking capabilities. For baby clothing, this property is combined with specific density levels to cater to diverse use cases.

When selecting organic bamboo fibers, manufacturers prioritize a density profile that is soft enough for sensitive skin but durable enough to withstand multiple washing cycles. Too low of a density leads to fragility, while too high restricts airflow and diminishes the naturally soft feel characteristic of bamboo. Engineers utilize advanced testing methods, such as compression and wear-resistance tests, to ensure that every batch of bamboo fabric meets rigorous infant safety and comfort standards.

For baby blankets and accessories, slightly higher fabric density provides warmth while maintaining bamboo’s inherent breathability. This controlled engineering allows the fabric to trap heat effectively without compromising on ventilation. It’s a delicate balance that requires adjustments throughout the manufacturing process, from fiber extraction to textile weaving.

Industrial Machinery Used in Manufacturing Organic Bamboo Fabrics

Modern advances in textile machinery have significantly streamlined the production of organic bamboo fabrics. At the heart of this process is the extraction and processing of bamboo into cellulose-based fibers, which are later transformed into yarn. Each production stage employs specific machines programmed for precision and efficiency.

One essential piece of machinery is the degumming system, which removes natural lignin and pectin from the bamboo stalks to isolate the cellulose. Chemical treatments must be carefully regulated to comply with organic certifications and ensure non-toxicity for baby-sensitive applications. Automated degumming machines equipped with sensors ensure adherence to environmental and safety standards.

Another important piece of industrial machinery is the carding machine, which aligns the fibers to form a uniform sheet. Ensuring uniformity in bamboo fibers directly impacts their tensile strength and resistance during the manufacturing stages. For baby clothes, softness is paramount, so carding machines are adjusted to avoid overcrowding, which could lead to overly compressed and less pliable textiles.

The spinning machines used in bamboo yarn production are calibrated to produce finer yarns for baby clothes. These machines can process bamboo into lightweight threads while maintaining sufficient structural integrity. Finally, weaving or knitting machines tailor the fabric GSM and density to meet desired specifications. Circular knitting machines, for example, are ideal for producing bamboo baby garments because they result in seamless, flexible fabrics that enhance comfort.

Sustainability Benefits of Organic Bamboo Baby Clothes

Organic bamboo baby clothes are not just optimized for technical excellence but also for their environmental advantages. Bamboo is one of the fastest-growing plants, requiring minimal resources such as water and pesticides. This makes it an eco-friendly alternative to traditional cotton and synthetic fabrics.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | ODM |

| Lead Time | 31 Days |

On the production side, properly engineered industrial machinery minimizes waste during fiber extraction and spinning. Recovery systems collect excess materials during the machining processes, reducing factory output waste and supporting zero-waste initiatives. Specialized machinery is also energy-efficient, using programmable logic controllers (PLCs) for automation that optimizes energy consumption during bamboo fiber manufacturing.

Additionally, bamboo fabrics are naturally hypoallergenic, antibacterial, and biodegradable, further amplifying their appeal for infant clothing. Parents are increasingly discerning about product sustainability, leading to higher demand for organic certifications. Suppliers of bamboo baby garments can gain competitive advantages through compliance with globally recognized standards like OEKO-TEX or GOTS (Global Organic Textile Standard).

Challenges in Engineering Bamboo Fabrics for Baby Clothes

While organic bamboo baby clothes offer distinct advantages, they also present engineering challenges. One of the primary obstacles is the variability in bamboo fiber quality, which can influence parameters such as GSM and tensile strength. Manufacturers must invest in rigorous quality control processes to ensure consistency, especially for infant-specific applications.

Another challenge lies in achieving the desired softness without compromising durability. Over-processing bamboo fibers can result in excessive wear during garment use, while under-processing leaves the fabric rough and unfit for sensitive skin. Engineers use advanced machinery equipped with real-time data analytics to strike a balance, monitoring fabric characteristics throughout production.

Lastly, the adoption of organic methods in bamboo processing can be cost-prohibitive for many manufacturers. Meeting eco-certification criteria often involves reconfiguring machinery and raw material procurement methods, which can increase production costs. Collaborative innovation between industrial machinery developers and textile manufacturers is essential to overcome this barrier while maintaining accessible price points.

Organic bamboo baby clothes represent a convergence of engineering precision, sustainability, and infant-centric garment design. With careful attention to fabric density, GSM, and processing machinery, manufacturers can deliver products that meet the highest safety and comfort standards for babies. By investing in advanced industrial technologies and sustainable practices, businesses can capitalize on growing consumer demand for eco-friendly baby garments while promoting long-term environmental benefits. The bamboo textile industry stands at the forefront of innovation, combining technical advancement with responsibility—a perfect fit for baby clothing.