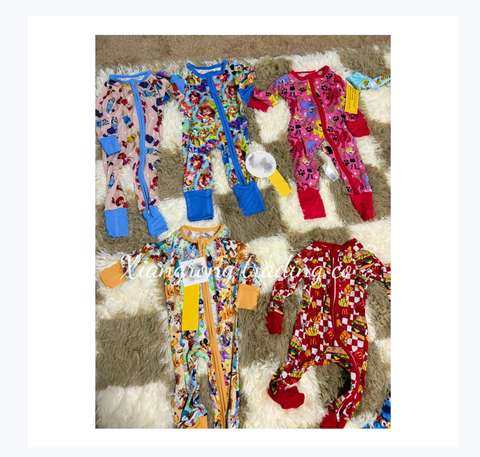

Odm Bamboo Clothing Ready To Ship Oem Manufacturer

Bamboo Clothing Ready to Ship: Technical Insights for B2B

In the modern textile industry, bamboo-based apparel has emerged as a leading innovation, offering sustainability, superior comfort, and durability. Successfully producing bamboo clothing that is “ready to ship” hinges on technical precision, involving precise fabric density (often measured in GSM), efficient industrial machinery, and streamlined manufacturing processes. This article unpacks key technical considerations for businesses interested in the production, procurement, or distribution of bamboo clothing at scale.

Understanding GSM and Fabric Density in Bamboo Clothing

GSM, or grams per square meter, is one of the most critical parameters in the production of fabrics, including bamboo textiles. It is a measure of fabric weight that directly correlates with its durability, feel, and application within the apparel market.

- Lightweight Bamboo Fabrics: Typically, bamboo fabrics with GSM values between 100 and 150 are used for lightweight garments such as t-shirts, undergarments, and summer dresses. These fabrics provide breathability and softness, making them ideal for warm weather.

- Medium Weight Bamboo Fabrics: A GSM range of 150 to 250 is common for activewear, casual shirts, and multi-season clothing. These offer optimal balance between durability and flexibility.

- Heavyweight Bamboo Fabrics: With GSM above 250, bamboo textiles become suitable for winter wear, outerwear, or upholstery applications. The higher fabric density provides insulation and robustness.

When selecting bamboo clothing for B2B purposes, understanding the GSM is indispensable. It not only ensures fit-for-purpose fabric but also influences the end consumer's experience with the product. Many buyers in the wholesale market request custom GSM values to align with regional climate or product functionality, creating the need for extremely precise manufacturing techniques.

The Role of Industrial Machinery in Bamboo Textile Production

To meet the increasing demand for eco-conscious apparel, manufacturers rely on advanced industrial machinery that balances efficiency, quality, and sustainability. Bamboo fabric production involves several critical stages, from fiber preparation to finishing, where machinery plays an integral role.

Fiber Processing Equipment

Bamboo clothing begins with the extraction and processing of bamboo fibers. The mechanical process involves crushing bamboo stalks followed by enzymatic treatment to separate fibers. Precision equipment ensures minimal waste and retains the strength and softness of bamboo fibers. Alternatively, the viscose process involves chemical treatment, which requires closed-loop machinery to ensure minimal environmental impact.

Weaving and Knitting Machines

The woven or knitted structure of bamboo fabric is achieved through technologically advanced machinery. For lightweight bamboo textiles, circular knitting machines are preferred, producing smooth, flexible fabrics suitable for undergarments. For applications like bamboo denim or jackets, high-tensile weaving machines create densely structured fabrics with high GSM.

Finishing Machinery

The final aesthetic and functional properties of bamboo fabric are achieved through finishing processes, which include dyeing, printing, and softening. Jet dyeing machines, pad dyeing systems, or digital printing technologies ensure vivid color retention without compromising the eco-friendly nature of bamboo fabric. Continuous open-width softening machines optimize the final texture of the cloth for direct consumer use.

Investments in state-of-the-art industrial machinery enable manufacturers to meet the demanding specifications of B2B clients in terms of GSM range, fabric density, and quality, ensuring the products are ready for shipment upon completion.

Production Processes for Ready-to-Ship Bamboo Apparel

Bamboo clothing that is designated as “ready to ship” requires streamlined production workflows and quality control for timely delivery, especially in bulk manufacturing environments. Below are the key stages within the production pipeline:

Precision Cutting and Automated Assembly

Once high-quality bamboo fabric is processed, it undergoes precision cutting through CNC automated cutting systems. These machines ensure minimal waste by optimizing patterns and cutting accuracy. Automated sewing machinery further accelerates the assembly process, meeting tight timelines without compromising quality.

Quality Control and GSM Verification

Quality checkpoints are embedded into the production process to ensure the bamboo fabric retains specified GSM and density levels. Textiles undergo weight and dimensional testing to ensure uniformity across batches. Tear strength and stretch assessments are also key, guaranteeing the garment's usability and life cycle.

Packaging and Inventory Management

Once the bamboo clothing is finalized, it is packaged using automated machinery designed for bulk apparel. Vacuum packing or folded, boxed packaging is often employed to optimize shipping logistics. QR codes and RFID tagging systems are integrated into the inventory, enabling tracking and seamless supply chain management.

Bamboo clothing has carved a niche as an eco-friendly and versatile textile solution, and its production involves a multi-faceted understanding of GSM, fabric density, and manufacturing technology. By leveraging industrial machinery, manufacturers can produce high-quality, ready-to-ship apparel at scale. Ensuring precision at every stage—from initial fiber extraction to final packaging—helps businesses meet the rising demand for sustainable fashion while maintaining their competitive edge.

| Fabric Type | Pima Cotton |

| Compliance | ASTM F963 |

| Customization | Private Label |

| Lead Time | 37 Days |

Businesses aiming to succeed in the bamboo clothing market must align their operations with the latest advancements in textile engineering and manufacturing technology. Doing so will be instrumental in delivering quality products that exceed client expectations while supporting environmentally conscious production practices.