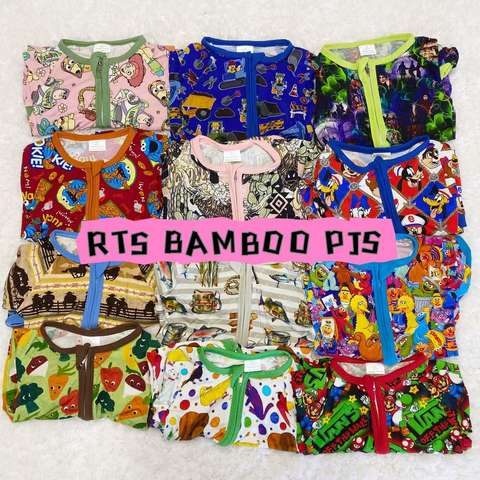

Odm Carhartt Bamboo Pajamas Tailormade Oem

The Technical Evolution of Carhartt Bamboo Pajamas

In recent years, advancements in textile engineering have transformed the way industries approach fabric design and production. Among these innovations, bamboo fabrics have gained significant traction for their sustainability, durability, and comfort. Carhartt, a brand renowned for its rugged workwear, has thoughtfully embraced this pioneering material, creating products like bamboo pajamas that marry superior performance with eco-conscious craftsmanship. This article will explore the technical aspects of GSM (grams per square meter), fabric density, and the industrial machinery utilized in creating Carhartt’s bamboo pajamas, highlighting their unique attributes for the business-to-business (B2B) market.

Understanding GSM and Its Contribution to Fabric Quality

In the textile industry, GSM stands as a critical metric that defines the weight of fabric per square meter. Simply put, GSM directly correlates with fabric density and durability. For Carhartt bamboo pajamas, ideal GSM values are chosen to balance softness, breathability, and robustness. The GSM of bamboo pajama fabric typically falls in the range of 180-250, ensuring it remains lightweight yet durable enough for everyday wear.

Carhartt leverages advanced GSM testing methods to tailor their bamboo fabric for specific applications. These tests, conducted using textile analysis tools such as digital GSM cutters and precision balances, ensure uniformity in fabric thickness and integrity across production batches. For B2B clients, GSM consistency is particularly crucial, as it guarantees reliability and repeatability in large-scale orders.

The Role of Fabric Density in Comfort and Longevity

Fabric density intertwines closely with GSM and plays a significant role in dictating the performance of textiles. High-density fabrics tend to be heavier, more durable, and better at retaining warmth, while low-density fabrics focus on lightness and breathability. For bamboo pajamas, achieving the right density is vital to ensure optimal comfort without compromising durability.

The densely woven bamboo fibers in Carhartt pajamas excel in flexibility and wear resistance. The use of bamboo-derived rayon optimizes moisture-wicking properties, ensuring these pajamas perform well in warm and cold conditions alike. This balance of high density and inherent bamboo characteristics makes them a preferred choice for B2B sectors looking for innovative solutions for employee uniforms, leisurewear, or branded apparel.

Industrial Machinery Tailored for Bamboo Fabric Production

The production of bamboo pajamas demands precision and scalability, requiring specialized industrial machinery. Bamboo fabric processing begins with extracting cellulose from bamboo stalks and converting it into yarn via viscose or lyocell methods. Each step utilizes dedicated machinery designed to handle bamboo’s unique characteristics.

- Carding and Spinning Machines: Highly calibrated equipment is required to transform bamboo fibers into smooth yarns. Modern rotor spinning systems are employed, which ensure uniform yarn quality essential for consistent fabric production.

- Knitting and Weaving Machines: Once spun, bamboo yarn is processed using circular knitting or shuttle weaving machines. For Carhartt’s bamboo pajamas, circular knitting machines are preferred, as they produce the soft, stretchable fabric often demanded in sleepwear.

- Dyeing and Finishing Equipment: Industrial dyeing machines play a key role in ensuring vibrant colors and resistance to fading. Bamboo fabric often undergoes enzyme-based finishing processes to enhance its already smooth texture and eliminate pilling.

Carhartt’s investment in state-of-the-art machinery not only ensures quality output but also appeals to B2B clients by offering cost-effective, large-scale production capabilities.

Sustainability and Eco-Friendly Manufacturing

Bamboo’s inherent sustainability makes it an attractive choice in industrial textile manufacturing. Bamboo grows rapidly, requires minimal water, and thrives without pesticides, making it an eco-friendly alternative to cotton, polyester, or other synthetic fibers. Carhartt capitalizes on this sustainability by implementing environmentally responsible manufacturing techniques.

The reduced energy footprint throughout the production chain—from yarn creation to final fabric assembly—significantly enhances the marketability of bamboo pajamas among businesses prioritizing green initiatives. , the use of recyclable industrial machinery and non-toxic raw materials in Carhartt factories underscores their commitment to eco-conscious production.

In addressing B2B concerns, Carhartt’s bamboo pajama offering aligns seamlessly with industries aiming to shift toward sustainable corporate practices while maintaining high-quality product output.

Versatility and B2B Applications

The technical blend of GSM, density, and machinery manifests in bamboo pajamas’ versatility, catering to diverse B2B markets. From corporate branded merchandise to hospitality staff attire, Carhartt’s expertise ensures their bamboo sleepwear serves multi-purpose functionality.

For example, hospitality resorts may opt for branded bamboo sleepwear due to its luxurious feel and hypoallergenic properties, while healthcare facilities value the antibacterial traits of bamboo fabric for their staff uniforms. In both cases, Carhartt’s bamboo pajamas offer an adaptable solution, meeting both aesthetic and performance-based industry demands.

Advantages of Carhartt Bamboo Pajamas Over Traditional Fabric Options

Carhartt’s strategic integration of bamboo fabric in pajamas offers clear advantages over conventional materials such as cotton or polyester. Businesses benefit from enhanced durability, comfort, and environmental sustainability, all while providing end-users with a premium feel.

- Moisture Management: Bamboo’s natural moisture-wicking ability outperforms cotton, making Carhartt pajamas suitable for humid environments.

- Temperature Regulation: The insulating properties of bamboo fibers allow for versatile temperature control, catering to a wide range of climates.

- Longevity and Wear Resistance: Bamboo pajamas resist frequent washing cycles and maintain their structural integrity better than synthetic alternatives.

B2B clients therefore gain long-term cost benefits, while still adhering to buyer expectations for high standards of comfort and performance.

Carhartt bamboo pajamas exemplify the successful fusion of engineering innovation, sustainable practices, and industrial efficiency in textile production. The meticulous approach to GSM, fabric density, and industrial machinery ensures a superior product that caters to both the end-user and B2B customer needs. From their scalability to environmentally-conscious credentials, these sleepwear solutions are well-poised to thrive within modern industries intent on delivering quality and sustainability simultaneously.

For businesses looking to invest in sustainable yet high-performance textiles, Carhartt bamboo pajamas stand as an excellent option, combining technical rigor with practical versatility in every stitch.

| Fabric Type | Pima Cotton |

| Compliance | CPSIA Compliant |

| Customization | Private Label |

| Lead Time | 23 Days |