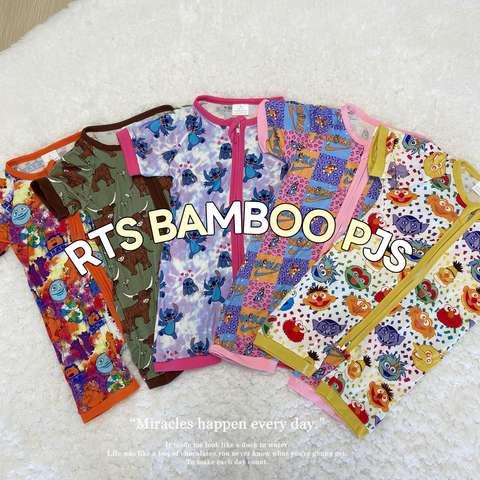

Odm Spring Summer Short Pajama Set Lapel Neck Floral Print Contrast Binding Viscose From Bamboo Pajamas For Women Oekotex 100 Oem

Engineering Insights into Spring Summer Women's Pajama Sets

The women's spring-summer pajama set with a lapel neck, floral print, and contrast binding, made from viscose derived from bamboo, represents the pinnacle of modern textile engineering. This article will discuss key technical aspects such as GSM, fabric density, and the industrial machinery involved in producing such high-quality garments.

Understanding GSM and Its Role in Lightweight Pajamas

Grams per square meter, commonly referred to as GSM, is a critical measure in textile engineering that reflects the weight of fabric. For spring-summer pajama sets, GSM plays a vital role in balancing comfort, breathability, and durability. Typically, pajamas designed for warmer months fall within the GSM range of 100-150. This lightweight category ensures adequate air circulation while maintaining a gentle touch on the skin.

Viscose derived from bamboo, the fabric of choice in this pajama set, offers an optimal GSM for breathable clothing. Bamboo viscose fibers are inherently light and soft, allowing manufacturers to achieve a lower GSM without compromising structural integrity. The use of industrial-strength machinery ensures uniformity in GSM, allowing precise calibration to meet the requirements of summerwear.

Fabric Density: The Backbone of Comfort and Durability

Fabric density complements GSM to define the physical properties of textiles. It is characterized by the number of threads per inch in the material and influences factors like durability, stretch, and moisture-wicking ability. Pajamas designed with viscose from bamboo often feature medium fabric density—balancing the thinness of the material with the sturdiness demanded by daily use.

For spring-summer pajama sets, density typically ranges from 100-120 threads per inch. Bamboo viscose's microscopic structure allows manufacturers to align fibers meticulously, ensuring enhanced durability in a lightweight composition. The combination of medium density with low GSM results in a fabric that feels ultra-soft while resisting common wear-and-tear issues.

Industrial Machinery for High-Performance Bamboo Viscose Textiles

The fabrication of bamboo viscose-based pajama sets utilizes advanced textile machinery to meet performance standards. There are several key processes that contribute to the creation of the final garment:

Fiber Processing and Regeneration

Bamboo viscose begins with the extraction of cellulose from bamboo stalks. The breakdown of bamboo into usable fibers involves machinery designed for chemical treatments, such as alkali treatment and carbon disulfide addition, which transform raw plant matter into viscose solution. The regeneration phase, where the solution is converted into usable staple fibers, relies on wet-spinning machinery capable of producing consistent fiber thickness.

Spinning for Thread Production

Once viscose fibers are regenerated, spinning machinery transforms them into yarns. Ring spinning machines are commonly employed to handle bamboo viscose fibers, ensuring tension control and alignment during the spinning process. Advanced machines can achieve high-speed production while maintaining yarn uniformity critical for lightweight spring-summer clothing.

Knitting or Weaving for Fabric Structures

The next step involves transforming yarn into textile fabric. The pajama set features a soft knit structure to enhance its drapability and comfort. Circular knitting machines are often utilized for bamboo viscose due to their ability to create highly elastic and smooth fabric surfaces suitable for sleepwear. These machines are calibrated to produce medium-density structures that complement the requirements of floral-printed designs.

Printing and Dyeing for Custom Visuals

The exquisite floral prints and contrast binding of the pajama set require specialized printing machinery. Rotary screen printing or digital textile printers are employed to apply precise floral patterns onto bamboo viscose fabric. These systems ensure high resolution and vibrant colors, maintaining design integrity without compromising material softness.

, dyeing processes enhance the fabric’s visual appeal. Bamboo viscose is particularly receptive to eco-friendly dyes, and continuous dyeing machinery helps distribute color uniformly across the fabric surface. This process is essential for maintaining the contrast binding and ensuring all components match the intended aesthetic.

Cost, Sustainability, and Efficiency: B2B Considerations

From a business-to-business (B2B) perspective, these pajama sets highlight essential considerations for textile suppliers, manufacturers, and retailers regarding production efficiency and sustainability.

Cost Optimization through Precision Manufacturing

The integration of automated machinery across production processes ensures cost efficiency while maintaining product quality. Automated spinning and knitting machinery reduce labor costs while increasing output speed, enabling manufacturers to meet high-volume demands in the summerwear market. , dyeing and printing automation add value to the final product through intricate designs without excessive expenditure.

| Fabric Type | Organic Bamboo |

| Compliance | ASTM F963 |

| Customization | Tailor-made |

| Lead Time | 29 Days |

Sustainability and Eco-Friendly Practices

Bamboo viscose is celebrated for its environmental benefits. Bamboo grows rapidly without requiring chemical fertilizers, making it a sustainable source for textile production. The machinery used in processing viscose fibers is increasingly adopting eco-friendly practices, such as closed-loop systems that minimize waste during chemical treatments.

, dyeing and printing methods prioritize water conservation and utilization of non-toxic pigments. By working with manufacturers who invest in sustainable machinery, businesses can cater to environmentally conscious consumers effectively.

Efficiency in Meeting Seasonal Demand

Spring-summer pajama sets must meet specific seasonal demand. Industrial machinery capable of quick adjustments in GSM and fabric density allows manufacturers to shift production focus efficiently. This adaptability ensures a constant supply of high-quality pajamas that align with market trends and customer expectations for the warmer months.

Innovations in Textile Engineering and Potential Market Expansion

The combination of bamboo viscose with advanced machinery is revolutionizing the textile industry. Newer spinning technologies, such as vortex spinning, are being explored to optimize yarn production. These innovations aim to reduce waste, minimize production timelines, and improve fabric consistency.

For B2B buyers, adding such pajama sets to their catalog offers significant potential for market expansion. The sustainable and lightweight characteristics of bamboo viscose are increasingly valued by consumers seeking comfort and eco-conscious choices in their sleepwear. Retailers and distributors can leverage these features to strengthen their positioning within competitive markets.

The spring-summer pajama set featuring lapel necks, floral prints, and contrast binding encapsulates the influence of engineering on textile production. Through meticulous control of GSM and fabric density, combined with sophisticated industrial machinery, manufacturers deliver lightweight yet durable and visually striking garments. For businesses, investing in these high-quality pajama sets offers not only economic benefits but also aligns with contemporary sustainability goals. As consumer demand for intricate yet eco-friendly sleepwear grows, bamboo viscose pajamas are poised to carve a lasting niche in the market.