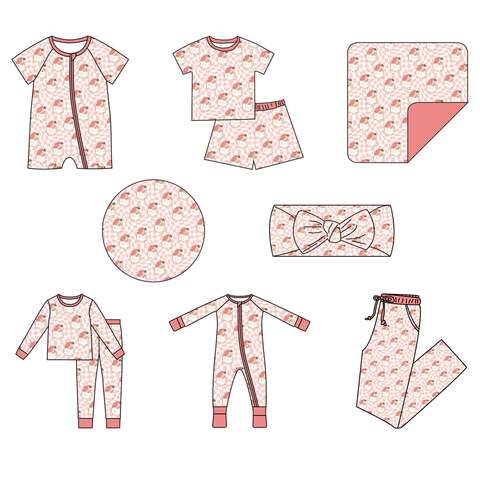

Oekotex 100 95 Bamboo 5 Spandex Family Christmas Pajamas Bespoke Supplier

Innovating Family Christmas Pajamas: The 95 Bamboo, 5 Spandex Blend

Family Christmas pajamas are a seasonal favorite, but the evolution of fabric engineering is transforming their production. The 95 bamboo, 5 spandex fabric blend represents a step forward in performance, comfort, and sustainability. This article explores the technical considerations that underpin its manufacturing, including GSM and fabric density, production machinery, and the challenges of working with blend configurations.

The Role of GSM in Fabric Performance

GSM, short for grams per square meter, is a significant metric in textile engineering. It determines the weight, thickness, and structural integrity of fabrics. For family Christmas pajamas made of 95 bamboo and 5 spandex, the target GSM is usually between 160 and 200. This range ensures the material is lightweight yet durable, breathable, and comfortable for extended wear during holiday festivities.

Bamboo fibers, known for their natural softness, contribute to the fabric's weight, while spandex adds elasticity without compromising breathability. Achieving an optimal GSM means balancing these attributes while ensuring the blend meets industry benchmarks for standard wear and tear.

Manufacturers need to evaluate GSM during the initial stages of fabric development to ensure compatibility with intended uses. Excessively high GSM can lead to stiffness, reducing wearability, whereas a lower GSM can compromise durability. Since family pajamas are typically lightweight with a slightly stretchable quality, precision in GSM calculations is pivotal.

Fabric Density and Stretch Optimization

Fabric density refers to the number of fibers packed into a given physical space. It plays a critical role in defining the texture, appearance, and durability of Christmas pajamas. The 95 bamboo/5 spandex blend exhibits an intricate structural configuration: bamboo increases the density for a rich aesthetic appeal, while spandex enhances flexibility for added comfort.

The thread count and fiber interlocking must be optimized to allow fabric stretchability within a controlled range. A uniform density facilitates consistent elasticity throughout the garment. For example, designing pajama seams with cohesive fiber orientation improves resistance to mechanical stress without altering the fabric's stretching properties.

The challenge lies in maintaining density while reducing piling and snagging. Bamboo fibers are prone to slight fuzziness, so employing advanced weaving techniques ensures minimal abrasion during wear or washing. Industrial engineers often incorporate reinforced knitting patterns to strike the perfect balance between density and flexibility.

Industrial Machinery for Manufacturing Bamboo-Spandex Pajamas

Producing high-quality family Christmas pajamas requires specialized industrial machinery capable of handling delicate bamboo fibers and spandex stretch characteristics. Traditional textile machines struggle to manage blended fabrics efficiently, necessitating advancements tailored to this hybrid construction.

The key machinery types employed include:

- Circular Knitting Machines: These machines are ideal for creating seamless pajama designs. Their capability to manage mixed threads with varying elasticity ensures that bamboo-spandex fabrics are knitted uniformly.

- Flatbed Knitting Machines: Best suited for heavier GSM materials, flatbed devices enable precise tension settings, critical for 95 bamboo/5 spandex blends. Engineers use these to ensure fine-tuning and eliminating thread inconsistencies.

- Dyers and Finishers: Bamboo fibers absorb dyes well, offering vibrant color retention. Dyeing machinery equipped with temperature control is crucial to prevent color fading while maintaining fabric integrity during processing.

- Cutting and Sewing Automation: The bamboo-spandex blend requires precision cutting and stitching due to its stretchable nature. Automated sewing machines with programmable settings improve efficiency while minimizing garment deformities.

Machine calibration demands attention to thread tension, needle type, and blending speed. Overworking spandex threads can lead to elasticity distortion, making calibration a non-negotiable component of production workflows.

Sustainability and Cost Considerations

Bamboo has gained prominence as a sustainable textile resource. Its rapid grow rate, low environmental impact, and biodegradability position it as an eco-friendly alternative to conventional fibers like polyester. Family Christmas pajamas made from a 95 bamboo/5 spandex blend tap directly into this sustainability narrative.

Spandex, though synthetic, plays a unique role in complementing bamboo’s limitations by adding stretch and longevity. Manufacturers must ensure it is procured from suppliers adhering to environmentally safe practices. Combining these fibers in optimal proportions minimizes waste during production and increases the garment’s lifecycle.

However, balancing sustainability with production costs presents certain challenges. Bamboo requires meticulous harvesting and processing, which can be more expensive than producing synthetic alternatives. For B2B clients, bulk orders and long-term contracts often present the best route to offset expenses while ensuring eco-conscious branding.

Manufacturing Quality Control and Testing

Industrial testing ensures the final product’s durability, elasticity, and comfort meet established standards. For 95 bamboo/5 spandex pajamas, quality control includes evaluating seam strength, stretch retention, and color stability.

Key tests include:

- Elastic Recovery Tests: These determine the spandex fibers’ resilience. Pajamas should retain their stretchability after multiple washes and wear cycles.

- Abrasion Resistance Testing: Bamboo fibers are tested for piling potential, ensuring a smooth finish even after extended use.

- Seam Integrity Checks: Industrial manufacturers simulate wear conditions to see how the fabric behaves under physical stress to prevent seam tearing.

- Dye Fastness Testing: Christmas pajamas typically boast bold, festive colors. Dye retention is verified to ensure the colors stay vibrant without fading during cleaning or storage.

Quality assurance should be incorporated as a continuous process, allowing manufacturers to identify and address flaws before production ups scaling.

Final Thoughts: Collaboration in Engineering Excellence

Creating 95 bamboo/5 spandex family Christmas pajamas is a feat demanding exceptional engineering collaboration. Backed by data-driven approaches to GSM calculations, fabric density optimization, advanced machinery, and rigorous quality control, manufacturers can deliver high-performance garments aligned with growing market demands.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | OEM |

| Lead Time | 39 Days |

B2B product development teams navigating this space must prioritize innovation without compromising sustainability or production efficiency. As technologies advance, leveraging next-generation machinery and fabric blends will continue to redefine what’s possible for holiday wear and beyond.