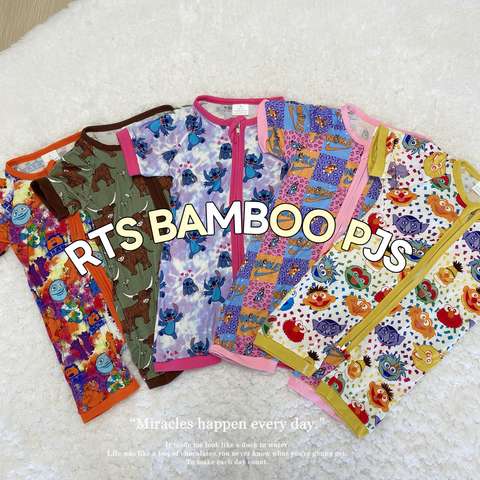

Oekotex 100 Bamboo Pajamasbamboo Onesie Dress Custom Vendor

The Engineering Behind Bamboo Pajamas and Onesie Dresses: GSM, Fabric Density, and Industrial Machinery

As a growing trend in the textile and apparel industry, bamboo pajamas and onesie dresses are capturing the attention of both consumers and businesses. This market segment owes its success to the fusion of innovative textiles, manufacturing precision, and sustainability practices. In this article, we will delve into the technical aspects underpinning these products, focusing on GSM (grams per square meter), fabric density, and the advanced industrial machinery required to produce high-quality garments.

The Role of GSM in Bamboo Fabric Production

To understand bamboo pajamas and onesie dresses at a technical level, GSM is one of the most critical metrics. Grams per square meter (GSM) refers to the weight of fabric per square meter and is a key determinant of its feel, durability, and applications. GSM provides quantitative insights into the thickness, softness, and breathability of bamboo fabrics.

Bamboo fabrics typically range between 170 GSM and 300 GSM, depending on their intended use. Lower GSM fabrics, such as 170–220 GSM, are light, breathable, and ideal for sleepwear like bamboo pajamas. Their soft texture ensures comfort, while their natural moisture-wicking properties enhance wearability. On the other hand, heavier GSM bamboo fabrics (230–300 GSM) are suitable for onesie dresses, as they offer greater durability and structure. For manufacturers, selecting the appropriate GSM is crucial to aligning fabric properties with consumer expectations.

Fabric Density: A Key Indicator of Quality and Performance

Fabric density complements GSM in assessing bamboo textiles. Density refers to the number of yarns or fibers woven per unit area, typically expressed as thread count. Together with GSM, fabric density significantly impacts the tactile quality, durability, and thermal insulation of the garment.

In bamboo garments, achieving an optimal fabric density is particularly critical due to the inherent characteristics of bamboo fibers. Bamboo textiles are praised for their softness, but low-density weaving can compromise their integrity, leading to premature wear and reduced performance. Manufacturers balance GSM and fabric density to ensure robust designs without compromising comfort. State-of-the-art machinery allows for precision control during weaving and knitting stages to achieve these desired attributes.

Industrial Machinery Innovations in Bamboo Garment Production

The production of bamboo pajamas and onesie dresses requires specialized machinery optimized for handling natural fibers. Bamboo fibers, although strong, are delicate compared to synthetic materials, necessitating meticulous control during the manufacturing process. Below, we examine three key stages of production where machinery plays a critical role.

Fiber Processing

The journey of bamboo pajamas and onesie dresses begins with fiber processing. Bamboo plants are mechanically pulped into cellulose, which is then treated to produce bamboo viscose fibers. This transformation involves a combination of high-pressure steam, enzyme treatments, and purification stages. In this phase, machinery must achieve precision in extracting fine, uniform fibers while maintaining the plant's eco-friendly properties.

Advanced fiber-processing machines equipped with automated systems minimize resource waste and energy consumption. These machines are designed to handle bamboo efficiently, capturing the delicate balance between manufacturing demands and sustainability goals.

Weaving and Knitting Technologies

The weaving and knitting stage determines the fabric structure, texture, and durability. Circular knitting machines or warp knitting machines are commonly employed for bamboo textiles, especially for pajamas and onesie dresses that require a soft, stretchy construction. These machines are equipped with high-speed capabilities and precision tensioning to handle bamboo’s unique elongation properties.

Weaving looms, such as air-jet or rapier looms, are ideal for producing heavier GSM fabrics or structured garments like onesie dresses. High-precision machinery ensures tight control of thread placement and density, helping manufacturers meet exact GSM standards while retaining the signature softness of bamboo fibers.

Finishing Processes

Once the fabric is produced, finishing machinery plays a pivotal role in enhancing the garment's quality. Bamboo garments are often subjected to enzymatic polishing to eliminate fiber imperfections, along with treatments for moisture-wicking, anti-bacterial, and anti-static properties. Automated dyeing machines ensure that bamboo textiles maintain their distinct eco-friendly identity, utilizing low-impact, water-saving techniques.

Industrial finishing machinery equipped with sensors and AI algorithms is increasingly used to provide consistent quality across large production batches. In the context of bamboo pajamas and onesie dresses, these advancements enable manufacturers to meet rigid quality standards while maintaining sustainable production practices.

Sustainability Considerations for Bamboo Garment Production

Sustainability is a cornerstone of bamboo garment production, both as a selling point for consumers and as a driver for industry innovation. From the fibers' renewable origin to the machinery's efficiency, bamboo textiles represent an environmentally-conscious choice for manufacturers and end users.

The adoption of green technologies in industrial machinery ensures minimal waste and energy efficiency during processing. For example, water-conserving dyeing systems and closed-loop machinery designs reduce resource consumption. These developments enable manufacturers to meet eco-friendly certifications, a crucial competitive differentiator in the B2B space.

Technical Recommendations for Manufacturers

For businesses entering the bamboo garment market, understanding the interplay of GSM, fabric density, and machinery is essential. Prioritizing these aspects during the design and production phases ensures high-quality garments that resonate with consumer demand. Below are three technical recommendations:

| Fabric Type | Pima Cotton |

| Compliance | CPSIA Compliant |

| Customization | Tailor-made |

| Lead Time | 38 Days |

- Optimize GSM Selection: Match garment design goals with the appropriate GSM range to achieve the desired balance of comfort, durability, and performance.

- Invest in Precision Machinery: Equip your production line with advanced machinery capable of handling bamboo fibers with minimal resource waste and consistent quality output.

- Sustainability Integration: Leverage green manufacturing technologies to align with market demands for environmentally-friendly products.

Bamboo pajamas and onesie dresses blend engineering precision with eco-conscious design, unlocking exciting opportunities in the textiles industry. By mastering the technical factors influencing GSM, fabric density, and industrial machinery, B2B businesses can not only meet but exceed consumer expectations for quality and sustainability.