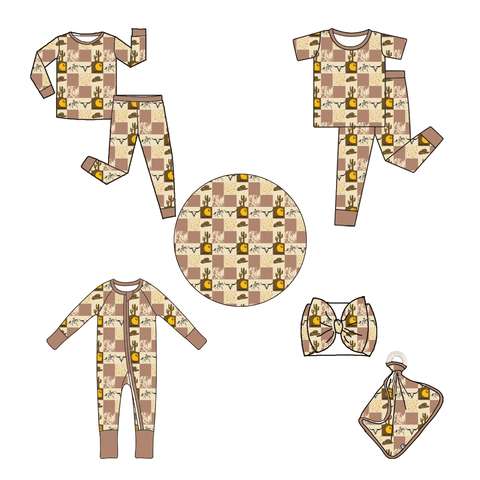

Oekotex 100 Wholesale Custom Halloween Toddler Newborn Boys Girls Bamboo Fiber Pajamas Baby Sleepwear Kid Infant Pajamas Sets Custom Supplier

Exploring Wholesale Custom Bamboo Fiber Pajamas for Toddlers: A Technical Perspective

The global demand for custom kids’ sleepwear, particularly bamboo fiber pajamas, continues to grow due to the material's softness, breathability, and eco-friendliness. Wholesale manufacturing of Halloween toddler, newborn, and infant pajamas requires a precise understanding of GSM (grams per square meter), fabric density, and the role of advanced industrial machinery to ensure cost-effectiveness, comfort, and durability. This article explores the technical aspects of producing high-quality bamboo fiber pajamas designed for toddlers and infants.

Understanding Bamboo Fiber Fabric: A High-Performance Material

Bamboo fiber has rapidly gained recognition as a premium material in the textile industry, particularly for baby and toddler clothing. This is largely due to its hypoallergenic, thermal-regulating, and moisture-wicking properties. With Halloween-themed pajamas in demand, manufacturers must create festive designs while maintaining the highest standards of softness and safety for sensitive skin.

Key features of bamboo fiber include:

- Eco-friendliness: Bamboo grows rapidly and requires fewer resources compared to conventional crops like cotton, making it a sustainable choice for manufacturers.

- Antibacterial properties: Bamboo’s natural ability to resist bacteria ensures that baby sleepwear is free from harmful pathogens.

- Moisture-wicking capabilities: Bamboo fabric absorbs moisture and keeps children dry, crucial for child comfort during sleep.

These properties make bamboo fiber ideal for toddler and infant pajamas, where safety and comfort are non-negotiable. However, achieving these characteristics requires precise focus on GSM and fabric density during manufacturing.

GSM and Its Importance in Bamboo Fiber Pajamas Production

GSM, or grams per square meter, is a key technical metric used in the textile industry to evaluate the weight and thickness of fabrics. For bamboo fiber pajamas intended for toddlers and infants, finding the optimal GSM balance is essential. A fabric that is too lightweight may compromise durability, while an overly dense fabric may restrict breathability and comfort.

When producing wholesale Halloween-themed bamboo pajamas, the recommended GSM range usually lies between 160 and 250:

- 160-190 GSM: Lightweight and breathable, ideal for summer and temperate climates. This range is excellent for ensuring toddlers stay cool during sleep.

- 200-250 GSM: Medium-weight fabrics suited for year-round comfort. This provides a balance of warmth and breathability, making it ideal for Halloween designs that may be worn in autumn or winter.

Manufacturers use high-precision equipment to ensure GSM consistency, which is critical in avoiding uneven patterns and fabric imperfections that can affect the feel and functionality of the final product.

Fabric Density: Ensuring Durability and Comfort

Fabric density refers to the number of threads per unit area, typically measured in terms of thread count. In wholesale production, the fabric density of bamboo fiber for kids' pajamas is carefully calibrated to ensure softness without sacrificing durability. A balance is crucial:

- Too low thread count: Can lead to a flimsy fabric prone to wear and tear.

- Too high thread count: May result in stiff, less breathable pajamas, which is uncomfortable for young children.

For kids and infant pajamas, the fabric density is best kept between 200 and 300 threads per square inch. This range ensures durability during frequent machine washes while maintaining the softness essential for sensitive baby skin.

, innovative knitting techniques such as circular knitting allow for more uniform density in bamboo fabrics. Special attention is given to elasticity, especially for products like pajamas and sleepwear, which require a degree of stretch for optimal fit and comfort during wear.

Industrial Machinery and Automation in Wholesale Manufacturing

The production of wholesale custom bamboo fiber pajamas heavily relies on advanced industrial machinery to deliver consistent quality at scale. Automated equipment allows manufacturers to meet large orders while maintaining strict standards for premium sleepwear.

Role of Circular Knitting Machines

High-performance circular knitting machines are essential for producing the stretchable and highly elastic fabric often used in kid's pajamas. These machines ensure even knitting patterns, which contribute to both fabric density and durability. Circular knitting is particularly suitable for bamboo fibers due to its ability to handle delicate materials without causing damage.

Dyeing and Printing Technology

With Halloween-themed kids’ sleepwear, bright and colorful designs are a focal point, especially for festive patterns like pumpkins, ghosts, and spooky motifs. To achieve long-lasting prints on bamboo fabric, advanced digital textile printers and dye-sublimation machines are utilized. These devices ensure vibrant, fade-resistant designs that withstand repeated washing while remaining safe for children’s delicate skin.

| Fabric Type | Organic Bamboo |

| Compliance | CPSIA Compliant |

| Customization | Tailor-made |

| Lead Time | 23 Days |

Cutting and Sewing Automation

Precision cutting machines and automated sewing equipment streamline the manufacturing process. Laser-guided cutting machinery ensures that the fabric is dimensionally accurate, minimizing material wastage and ensuring uniformity in multi-piece orders. Automated sewing ensures consistent stitching, which contributes to the longevity of the pajamas.

Batch Production Efficiency and Quality Assurance

Wholesale manufacturing of kids' bamboo fiber pajamas not only depends on high-tech machinery but also requires robust quality assurance processes to maintain standards for safety and comfort. Advanced sensors installed in production lines continuously monitor fabric weight, composition, and weaving consistency.

Additionally, post-manufacturing tests are performed to assess shrinkage, colorfastness, and stitching strength. These measures ensure the product complies with international safety regulations for children’s clothing, such as CPSIA (Consumer Product Safety Improvement Act) standards in the U.S.

Challenges and Future Innovations in Bamboo Fiber Kids’ Clothing

Despite the advantages of bamboo fiber, manufacturers face challenges in scaling production. Bamboo fabric is prone to pilling, which requires additional processing steps like singeing or enzyme washes to mitigate. Advanced machinery that integrates these processes seamlessly could reduce production times and costs, boosting efficiency within the industry.

Looking forward, innovations such as AI-driven textile machinery and smart manufacturing ecosystems offer significant potential. By adopting predictive maintenance for equipment and relying on automated defect detection, manufacturers can significantly enhance productivity and product quality. Additionally, biodegradable dyes and sustainable sourcing of bamboo will further support eco-conscious manufacturing for baby and toddler products.

The Business Case for Wholesale Custom Bamboo Fiber Sleepwear

The production of wholesale, Halloween-themed bamboo pajamas for toddlers and infants represents a lucrative market opportunity for businesses that prioritize eco-friendly and high-quality products. With the growing demand for sustainable children’s clothing, companies investing in advanced manufacturing technologies and high-quality materials will be poised for long-term success.

By focusing on optimal GSM, fabric density, and leveraging cutting-edge industrial machinery, businesses can deliver products that meet and exceed consumer expectations. The result is premium sleepwear that is both functional and festive, capturing market demand during seasonal spikes like Halloween while building brand loyalty through superior quality.