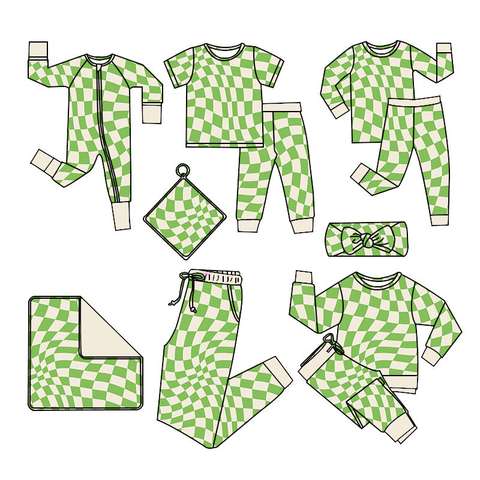

Oem Kids Bamboo Sleepers Private Label Wholesale

Optimizing Kids Bamboo Sleepers: A Harmony of Comfort, Sustainability, and Precision Manufacturing

As consumer demand for eco-friendly and sustainable products continues to increase, industries across the globe are responding with innovative solutions. One such product that has gained prominence in recent years is kids bamboo sleepers. These garments offer a blend of exceptional comfort, sustainable sourcing, and sophisticated manufacturing processes. When crafting kids bamboo sleepers, engineers and manufacturers must consider crucial factors like GSM (grams per square meter), fabric density, and the integration of advanced machinery to ensure product quality, durability, and scalability for B2B operations.

Understanding Bamboo Fabric: The Foundation of Superior Kids Sleepwear

Bamboo fabric stands out due to its natural softness, breathability, and hypoallergenic properties, making it ideal for children’s delicate skin. However, producing bamboo fabric requires technical precision to maintain these qualities while ensuring the material meets industrial standards for wear resistance and durability.

At the core of bamboo textile manufacturing is the careful transformation of bamboo pulp into tunable fibers. These fibers are spun and woven into fabric with specific properties determined by GSM and fabric density, two critical metrics in textile engineering.

The Role of GSM in Bamboo Sleepers

GSM, or grams per square meter, measures a fabric's weight and plays a pivotal role in understanding the durability and comfort of kids bamboo sleepers. For children’s sleepwear, the GSM needs to be balanced—high enough to withstand wear but low enough to ensure softness and breathability.

Typically, children's bamboo garments have GSM values between 150 and 250, depending on the intended season or application. For summer sleepers, lower GSM values (150-170) are preferred for lightweight and airy fabrics, while thicker materials with GSM values closer to 250 are more suitable for colder climates. Engineers collaborate with material scientists to align GSM ratings with product design specifications while preserving the bamboo fibers’ inherent qualities.

Fabric Density: Ensuring Structural Integrity

Fabric density refers to the arrangement of fibers within a textile surface and directly impacts its texture, resilience, and warmth. Bamboo fabric’s tight weave structure ensures durability, while maintaining the softness essential for kids’ garments.

For high-quality bamboo sleepers, it’s crucial that manufacturers balance fabric density with GSM. A higher GSM combined with loose fabric density can lead to excessive bulkiness, whereas overly dense fibers may compromise the garment’s breathability. Machinery such as weave machines and circular knit machines is calibrated to ensure uniform fabric density, enabling the production of consistent batches with standardized performance characteristics.

Advanced Industrial Machinery in Bamboo Sleepwear Manufacturing

The creation of kids bamboo sleepers goes beyond material composition; it involves the use of sophisticated machinery that enables precision manufacturing and scalability. Here are critical equipment categories utilized in production:

Spinning Machinery: Transforming Bamboo Pulp into Usable Fiber

The production process begins with spinning machinery, which converts bamboo pulp into viscose rayon fibers. Machines equipped with advanced spindle technologies are calibrated for optimized spinning speeds, minimizing fiber breakage and ensuring uniformity in fiber diameter. Automated spinning systems enable higher throughput and consistent quality while reducing human intervention.

Knitting and Weaving Machines: Maximizing Fabric Uniformity

Machines like circular knitting machines and shuttleless looms play a central role in producing the fabric for kids bamboo sleepers. Circular knitting machines are designed with precision needle systems to handle bamboo fibers’ unique elasticity and thread counts effectively.

Shuttleless looms ensure a seamless weaving process, reducing fabric imperfections and allowing for tighter control over thread density, which impacts the structural performance of bamboo sleepers. Modern machinery also integrates sensors and computer-controlled modules for real-time monitoring, enabling manufacturers to detect and rectify errors in the production process promptly.

Cutting and Sewing Machinery: Bringing Garments to Life

High-speed cutting machines with laser precision provide accurate and efficient cutting of bamboo fabric, minimizing material wastage. Once the fabric is cut, automated sewing machines equipped with programmable stitching patterns assemble the garments. These machines allow for scalable production, maintaining uniformity in stitching and seam quality across batches.

Sustainability in Kids Bamboo Sleepers Manufacturing

Bamboo's status as a renewable resource aligns perfectly with the growing demand for sustainable practices in textile manufacturing. From sourcing to production, engineers play a crucial role in ensuring environmental stewardship without compromising efficiency or product quality.

| Fabric Type | Organic Bamboo |

| Compliance | CPC Certified |

| Customization | Bespoke |

| Lead Time | 34 Days |

Eco-Friendly Production Practices

Manufacturers employ enzyme-based treatments rather than harsh chemicals during bamboo fiber production, resulting in more sustainable processing and reduced environmental impact. Wastewater treatment systems integrated into production facilities recycle water, ensuring minimal resource consumption.

When paired with energy-efficient machinery, these practices contribute to manufacturing processes that align with eco-conscious business models.

Recyclability and Lifecycle Management

Keen attention is paid to the recyclability of bamboo fabrics. Unlike synthetic materials, bamboo sleepers decompose naturally, posing no harm to the environment when properly disposed of. Engineers actively design bamboo garments with lifecycle considerations, allowing businesses to market these products as a sustainable alternative to conventional sleepwear.

The Value Proposition for Businesses

Kids bamboo sleepers offer significant opportunities for businesses in the textile sector seeking to expand into eco-friendly product ranges. For B2B buyers, the combination of technical precision, high-quality manufacturing, and sustainability makes bamboo sleepers a lucrative option for diversification.

Manufacturers can leverage advanced machinery, optimized GSM configurations, and fabric density control to ensure reliable scalability and competitive pricing. With bamboo fibers’ inherent qualities and innovative production processes, businesses are positioned to address growing consumer demands for kids' garments that prioritize comfort, safety, and environmental stewardship.