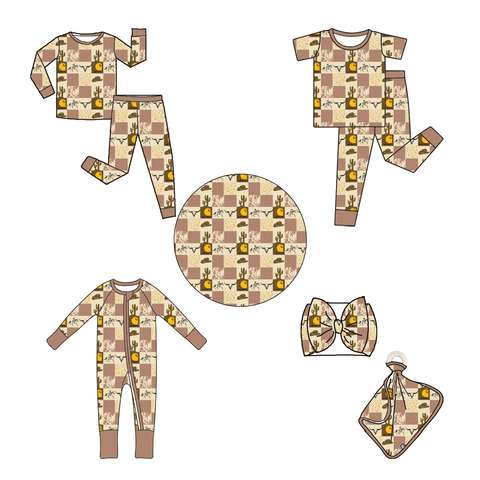

Tailormade Baby Bamboo Pajamas Romper Cpsia Compliant Supplier

The Industrial Science Behind Baby Bamboo Pajamas Rompers

As industries evolve, the combination of sustainable materials and advanced machinery has resulted in high-quality products that cater to consumer needs. One such marvel is the baby bamboo pajamas romper, a product that merges softness, durability, and environmental stewardship. This article delves into the underlying technicalities that make bamboo rompers a standout product, focusing on GSM, fabric density, and the machinery involved in production.

Understanding Bamboo Fabric: A Sustainable Revolution

Bamboo, a natural and renewable resource, has become a cornerstone of sustainable textile manufacturing. Its transformation from raw fiber to fabric requires advanced engineering processes to maintain its softness and durability while achieving the desired technical specifications.

The hallmark of bamboo as a textile lies in its ability to combine eco-consciousness with performance characteristics. Bamboo fibers are naturally soft yet durable, making them ideal for baby wear, such as pajamas rompers, where comfort and resilience are critical metrics for performance.

GSM and Fabric Density: Engineering the Perfect Pajama

When manufacturing baby bamboo pajamas rompers, GSM (grams per square meter) and fabric density are essential factors that dictate quality. These specifications balance comfort, durability, and breathability while maintaining manufacturing efficiency.

What is GSM in Fabric Manufacturing?

GSM stands for grams per square meter, a standardized measure of fabric weight and thickness. For baby rompers, the recommended GSM usually ranges between 160 to 220 GSM. This range ensures that the romper is lightweight yet sturdy enough to withstand frequent washing and wear. Too low a GSM might lead to a flimsy product, while too high a GSM could compromise breathability, essential for infant clothing.

Optimal Fabric Density for Baby Wear

Fabric density refers to the tightness with which fibers are woven or knitted together. Bamboo fabrics used in baby rompers are typically produced as jersey or interlock knits. Both methods result in a material that is soft to the touch yet engineered for performance.

Interlock knitting results in a double-sided fabric that is thicker, offering extra structure and durability. On the other hand, jersey knits are lighter and stretchier. The choice between these knitting techniques is often determined by the romper's intended GSM and design.

The Role of Fabric Finishing in Achieving Optimal Density

After raw textile production, fabric finishing processes like pre-shrinking, enzyme washing, and mercerization can further refine fabric density. These post-production steps enhance the romper's softness while maintaining structural integrity, ensuring it holds up to industrial laundering and prolonged use.

Industrial Machinery Used for Manufacturing Bamboo Rompers

The production of baby bamboo pajamas rompers relies on state-of-the-art industrial machinery tailored for precision, consistency, and scalability. Below, we explore the key types of machinery and their roles in the manufacturing process.

1. Bamboo Fiber Processing Machines

To transform bamboo into yarn, manufacturers employ specialized extraction and retting machinery. This process often begins with crushing raw bamboo into a pulp and breaking it down chemically or mechanically to extract cellulose fibers. The fibers are then spun into threads or yarn using ring-spinning or open-end spinning machines.

Ring-spinning machines are favored for producing fine, strong yarns suitable for baby wear, as they ensure uniformity and superior texture.

2. Circular Knitting Machines

Once the bamboo yarn has been prepared, it is fed into circular knitting machines. These machines knit the fabric in a tube-like fashion, ensuring even tension throughout the material. The gauges of the knitting machine—indicating the number of needles per inch—determine the fabric's tightness and density. For bamboo rompers, machines with medium-to-high gauges (e.g., 28-32 gauge) are typically used to achieve a soft, breathable texture.

3. Dyeing and Printing Machines

The finishing stage involves dyeing and printing, where industrial dyeing machines are calibrated to achieve uniform color-fastness. For bamboo fabrics, low-impact reactive dyes are often used, ensuring the romper is both vivid in color and safe for sensitive baby skin.

Digital printing machines enable intricate designs to be applied to bamboo rompers, offering customization options for modern parents without compromising on the safety or tactile experience of the fabric.

| Fabric Type | Organic Bamboo |

| Compliance | ASTM F963 |

| Customization | Bespoke |

| Lead Time | 31 Days |

4. Industrial Sewing Machines

Finally, the fabric is cut into patterns and stitched into rompers using industrial sewing machines. Overlock and flatlock machines are frequently employed to create durable yet soft seams, ensuring that there is no irritation on a baby's skin. For added versatility, programmable sewing machines can perform functions like buttonholing and zipper stitching with high precision.

Quality Assurance and Product Testing

After production, baby bamboo pajamas rompers undergo rigorous quality testing. Common procedures include:

- GSM Verification: Ensuring the fabric complies with the predetermined specifications.

- Stretch Recovery Tests: Evaluating the material's ability to return to its original form after being stretched, guaranteeing durability.

- Color-Fastness Testing: Ensuring dyes do not bleed or fade during washing.

- Safety Certifications: Verifying that the product meets required standards for infant wear, such as OEKO-TEX Standard 100.

These tests ensure a high-quality final product that provides comfort, safety, and durability to end consumers.

: Engineering Excellence in Baby Bamboo Pajamas Rompers

The production of baby bamboo pajamas rompers exemplifies the harmony between sustainability, material science, and industrial engineering. By carefully controlling GSM, fabric density, and leveraging state-of-the-art machinery, manufacturers can deliver a product that is soft, durable, eco-friendly, and safe for infants. As the industry continues to prioritize sustainability and functional design, bamboo rompers serve as a benchmark for innovation in textile technology.

For companies looking to enter this market, investing in precision machinery, understanding fabric metrics, and adhering to strict quality standards will be crucial to ensuring success in the competitive babywear industry.