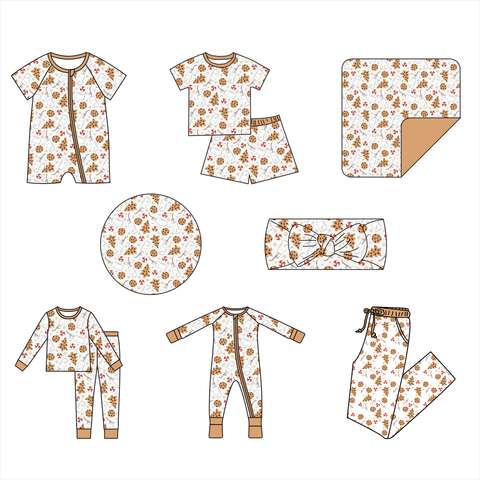

Tailormade Bamboo Bamboo Pajamas Custom Oem

Bamboo Pajamas: Revolutionizing Comfort and Sustainability

Bamboo pajamas have rapidly carved a niche for themselves in the fabric and textile industry. Known for their unmatched softness, breathability, and sustainability, they represent a pinnacle in modern sleepwear innovation. The production of bamboo pajamas is a complex process, requiring precise control of fabric density, GSM (grams per square meter), and industrial machinery. In this article, we delve into the engineering and technical underpinnings of bamboo pajamas, particularly focusing on their material properties and the machinery used to manufacture them efficiently and at scale.

Fabric Density and Its Role in Bamboo Pajamas

Fabric density is one of the most critical factors determining the comfort, durability, and functionality of bamboo pajamas. Measured in grams per square meter (GSM), it directly correlates to the fabric’s weight and thickness. For bamboo pajamas, an optimal GSM typically falls between 150 and 300 GSM.

A lower GSM (e.g., 150 GSM) results in lighter, more breathable bamboo fabric—ideal for warmer climates. In contrast, a higher GSM (e.g., 300 GSM) produces thicker pajamas suited for cooler environments, offering better insulation. Achieving the right balance in fabric density requires precision in fiber weaving and processing.

- 150-200 GSM: Provides an airy, lightweight feel. Perfect for summer pajamas, but may lack durability for extended use.

- 200-250 GSM: Balances softness and durability, making it the most frequent choice for year-round comfort wear.

- 250-300 GSM: Thicker bamboo fabric used for colder climates, offering premium insulation without sacrificing breathability.

The engineering challenge here lies in creating a fabric that remains soft, even at higher densities. Bamboo’s unique cellular structure allows manufacturers to produce a silky texture at high threads per inch (TPI), achieving premium quality at a desired GSM level.

Industrial Machinery in Bamboo Fabric Production

The production of bamboo fabric—the foundation of bamboo pajamas—relies heavily on precision industrial machinery. From fiber extraction to weaving and dyeing, every stage involves advanced technologies. Here are the key stages:

Fiber Processing Machinery

The production process begins with the mechanical or chemical breakdown of bamboo stalks into cellulose fibers. While there are two main methods—mechanical processing and chemical processing—most industrial-scale bamboo production uses chemical processing due to its efficiency.

Key machinery includes:

- Bamboo Cutting Machines: Slice bamboo stalks into smaller chips to prepare them for chemical or mechanical treatment.

- In chemical processing, these digesters use solutions (like lye) to break down the cellulose from bamboo chips, forming a viscose solution.

- Mechanical Crimpers: Used in sustainable processes, these machines mechanically extract raw fibers without the use of harsh chemicals.

Spinning and Yarn Formation

Once bamboo fibers are extracted, they are spun into yarns. This step defines many characteristics, such as the eventual softness, elasticity, and durability of the bamboo pajamas.

Key machinery includes:

| Fabric Type | Pima Cotton |

| Compliance | OEKO-TEX 100 |

| Customization | Custom |

| Lead Time | 16 Days |

- Ring Spinning Machines: These create high-quality, smooth yarns that are crucial for the soft-textured finish associated with bamboo fabrics.

- Open-End (Rotor) Spinning Machines: These are deployed when blended fabrics, such as bamboo-cotton, are needed for industrial applications or specific fabric properties.

Weaving and Knitting Equipment

The nature of bamboo fabric—whether it’s woven or knit—depends on the machinery used during this stage. Knit fabrics, made using circular knitting machines, emphasize elasticity and stretch, making them suitable for comfortable loungewear and pajamas. On the other hand, woven fabrics, created using shuttle looms or air jet looms, achieve a more structured and durable finish.

Dyeing and Finishing

Once the fabric is woven or knit, the dyeing and finishing stages are crucial. Bamboo fabric’s excellent dye absorbency means that attention to eco-friendly dyeing methods is paramount. Advanced dyeing technologies such as jet dyeing machines and computerized dosing systems ensure consistent color application while minimizing water and chemical consumption.

The Sustainability of Bamboo Pajamas

Bamboo’s reputation as a sustainable resource isn’t without merit. By nature, bamboo is a rapidly renewable plant that grows without the need for pesticides or excessive water. However, it’s essential to differentiate between its raw, eco-friendly potential and the engineering challenges associated with its manufacturing.

Water and Chemical Use

While bamboo itself grows sustainably, the chemical processes used to turn bamboo into viscose or rayon can involve substances such as sodium hydroxide. For brands producing eco-friendly Bamboo pajamas use a closed loop-altox.