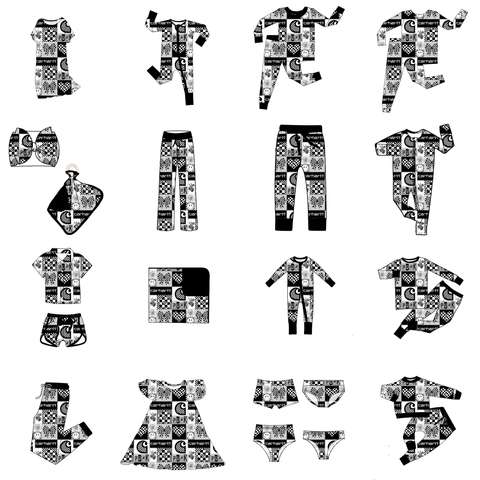

Tailormade Bamboo Pajamas Adult Cpc Certified Wholesale

Innovations in Bamboo Pajamas for Adults: A Look Behind the Scenes

The textile industry is undergoing a sustainable transformation, and bamboo fabric has taken center stage. Among its wide applications, bamboo-derived material is now a top choice for premium adult pajamas. These garments combine luxury and eco-friendliness, satisfying both consumers and businesses. But what makes bamboo pajamas exceptional is the harmonious interplay of material GSM (grams per square meter), optimal fabric density, and the precision of industrial machinery used in their production. This article explores the technical framework enabling companies to create high-quality bamboo pajamas that meet industry standards and customer expectations.

Understanding the Role of GSM in Bamboo Pajamas

GSM, or grams per square meter, is a critical specification for textiles. It quantifies the weight of fabric over a given surface area, determining the balance between softness, durability, and breathability. For bamboo pajamas designed for adults, the GSM typically falls in the range of 150-220. This GSM range signifies a sweet spot where the fabric feels lightweight and breathable, yet durable enough for repeated wear and washing.

For manufacturers, achieving the ideal GSM involves a precise combination of bamboo fiber thickness and yarn spinning techniques. The fiber itself is treated using closed-loop processes to extract cellulose, ensuring an eco-friendly manufacturing workflow. Once the bamboo pulp is transformed into threads, specific weaving patterns (e.g., interlock or jersey knits) are employed to regulate the GSM and ensure fabric consistency across production batches. High-tech textile testing equipment is then used to verify GSM metrics and meet B2B quality parameters.

The Science of Fabric Density in Bamboo Pajama Construction

Fabric density is another essential aspect impacting comfort and performance. Defined as the number of threads packed into a square inch of fabric, fabric density directly affects how soft, breathable, and durable the final bamboo pajamas feel to the wearer.

For bamboo pajamas geared toward adult consumers, a moderate density of 200-400 threads per square inch is often the target. This strikes a balance between achieving an ultra-soft hand feel and allowing sufficient permeability for moisture-wicking properties. Bamboo fabric inherently excels in thermal regulation, but fabric density fine-tunes the material to suit different climates and use cases. Manufacturers typically balance warp and weft thread counts with precision—a task accomplished through automated weaving machines such as air-jet or rapier looms.

Automation plays a key role as industrial machinery ensures uniform thread distribution, preventing fabric imperfections like uneven density or surface pilling. , advanced quality assurance (QA) systems embedded in weaving machines use AI algorithms and real-time monitoring tools to identify flaws before the material proceeds to downstream processes, such as dyeing and cutting.

| Fabric Type | Pima Cotton |

| Compliance | ASTM F963 |

| Customization | Bespoke |

| Lead Time | 18 Days |

Industrial Machinery Facilitating Scalable Production

The seamless production of bamboo pajamas is enabled by a range of advanced machinery, from fiber extrusion systems to garment assembly lines. Each piece of equipment is critical in ensuring the final product adheres to the desired GSM, fabric density, and quality standards. Here are some key systems used in the production process:

- Bamboo Pulp to Fiber Conversion: This begins with mechanically or chemically processing bamboo poles into pulp, which is then extruded through spinnerets to form viscose fibers. Closed-loop systems like Lenzing™ technology minimize ecological impact by recycling water and chemicals used during production.

- Knitting and Weaving Machines: Circular knitting machines create soft and flexible jersey knits optimal for pajamas, while automated looms handle woven designs for more structured garments. Parameters such as tension control and thread density can be preset, allowing manufacturers to replicate designs with high precision.

- Dyeing and Finishing Equipment: Low-water dyeing technologies, such as those developed by Thies™ or Fong’s™, are particularly favored for bamboo-blend fabrics. These systems retain eco-credentials while delivering consistent and vibrant colors that enhance the pajama’s visual appeal.

- Garment Sewing and Assembly Lines: Precision sewing machines with programmable logic controllers (PLCs) ensure consistent stitching patterns, while laser cutting tools streamline fabric shaping to minimize waste. Increasingly, robotic automation is being integrated into assembly lines, reducing lead times dramatically.

Sustainability and Performance: A Core Selling Proposition

Environmental responsibility is a key driver for businesses investing in bamboo fabric, especially when creating items like pajamas that demand both comfort and long-term performance. Bamboo fiber stands out due to its natural advantages, including anti-bacterial properties, moisture-wicking capabilities, and biodegradability. Ensuring these qualities are preserved across manufacturing requires precision control over GSM, density, and finishing processes.

For B2B partnerships, offering transparency on the eco-friendly aspects of production is critical. Implementing supply chain tracking systems, such as blockchain-based platforms, can assure clients that the entire production process—from bamboo harvesting to final garment delivery—adheres to sustainability commitments. , incorporating certifications like OEKO-TEX® or GOTS (Global Organic Textile Standard) further strengthens partnerships and drives business growth in eco-conscious markets.

Practical Considerations for Industry Collaborations

Businesses seeking to enter the bamboo pajama market or expand their existing operations should consider several practical factors when partnering with manufacturers:

- GSM Customization: Collaborate with suppliers who offer GSM adjustability based on seasonal or customer-specific requirements.

- Scalable Machinery: Ensure that production facilities utilize industrial machinery capable of scaling operations without significant downtime or retooling.

- Quality Control Systems: Work with manufacturers employing robust QA protocols to ensure consistent results across mass production runs.

- Eco-Certifications: Verify compliance with environmental standards to meet consumer demand for sustainable products.

The Future of Bamboo Pajamas and Production Technology

As demand for sustainable textiles continues to grow, the future of bamboo pajama production looks bright. Innovations in machinery are making scalable and eco-friendly production a reality. smart factories equipped with IoT-enabled devices and artificial intelligence are optimizing every stage of the manufacturing process, from fiber processing to final garment finishing. Additionally, advancements in bamboo fiber blends, such as those combining bamboo with organic cotton or elastane, are opening new design possibilities for adult pajama collections.

Looking ahead, collaborations between textile manufacturers, designers, and industrial engineers will be essential in pushing the boundaries of what’s possible in bamboo apparel. With a continued focus on GSM, fabric density, and precision engineering, the bamboo pajama market is set to become a cornerstone of sustainable luxury.