Tailormade Christmas Bamboo Pajamas Private Label Factory

Understanding Christmas Bamboo Pajamas: GSM, Fabric Density, and Industrial Machinery

In the realm of apparel manufacturing, the fusion of sustainability, comfort, and aesthetic appeal has driven the rising demand for bamboo fabric. Christmas bamboo pajamas epitomize this trend, showcasing not only elegant seasonal designs but also advanced engineering concepts behind their creation. This article dives into the technical aspects of bamboo fabric production, including GSM (grams per square meter), fabric density, and the industrial machinery employed to transform raw bamboo and designs into high-quality seasonal garments.

The Role of Bamboo Fabric in Modern Apparel

Bamboo fabric has gained prominence for its eco-friendly properties, softness, and ability to regulate temperature, making it a prime candidate for manufacturing pajamas, especially those worn during the colder holiday season. By its fibrous nature, bamboo offers compelling features such as enhanced durability and moisture-wicking capabilities. These attributes ensure that Christmas bamboo pajamas are not just festive but also practical.

Grams Per Square Meter (GSM): The Key to Fabric Quality

To understand the technicalities behind bamboo pajamas, we must first examine GSM, a critical parameter in textile engineering. GSM is a measurement of fabric weight that directly impacts the garment’s thickness, texture, and durability.

For bamboo pajamas, the appropriate GSM typically ranges between 200 and 300, striking a balance between lightweight comfort and sufficient insulation. A GSM above 300 would render the fabric overly thick and less comfortable for pajamas, while a GSM below 200 risks compromising durability and warmth. The selection of GSM must align with the seasonal use of the garment, ensuring prime functionality during the colder Christmas season.

Industrially, GSM calibration is achieved through optimized layering and compaction processes. Machinery using precision rollers and automated calibration devices ensures uniformity in GSM across the stretched fabric, maintaining consistency for large-scale production.

Fabric Density and Its Impact on Product Quality

Fabric density, or the number of yarns per unit area, complements GSM in determining the feel and performance of bamboo pajamas. While GSM gauges weight, density captures the structural integrity of the fabric. For bamboo textiles, balancing density is crucial due to the inherent flexibility and softness of the fibers.

When producing Christmas bamboo pajamas, manufacturers aim for medium-density weaves to retain bamboo’s signature softness while ensuring sufficient warmth for cold environments. Dense fabric also enhances the vibrancy of seasonal prints, ensuring the iconic Christmas patterns are visually striking.

Achieving the desired fabric density involves intricate weaving processes on industrial looms. High-speed looms capable of controlling thread tension and pattern alignment produce precise results, ensuring uniform density across batches. These machines, combined with automated inspection systems, catch discrepancies early in the production phase.

Industrial Machinery in Bamboo Pajama Manufacturing

Behind the scenes, an array of industrial machinery drives the transformation of bamboo into luxurious pajamas. The engineering marvel starts with cellulose extraction, which involves breaking down bamboo into its fibrous structure. Specialized machinery in this stage includes crushing rollers and enzyme-based digesters, which prepare raw bamboo fibers for spinning.

Once the fibers are processed, they move to spinning machines where threads are formed. These threads undergo tension-controlled spinning to ensure that their thickness aligns with the fabric specifications determined by GSM and density requirements. From there, the bamboo threads are woven or knitted on mechanized looms, which utilize programmable weaving patterns for enhanced precision and customization such as creating visually appealing holiday motifs.

| Fabric Type | Pima Cotton |

| Compliance | OEKO-TEX 100 |

| Customization | Custom |

| Lead Time | 20 Days |

Digital dyeing systems play a key role in integrating vibrant Christmas patterns into bamboo pajamas. Advanced machinery ensures color fidelity while minimizing water and chemical usage – a sustainability win that aligns with the eco-friendly ethos of bamboo fabric.

Finally, finishing machinery enhances the fabric’s softness and elasticity. Heated rollers, compression pre-shrink systems, and softening sprays are often employed to improve the final texture before cutting and stitching operations commence.

Design Optimization for Seasonal Bamboo Pajamas

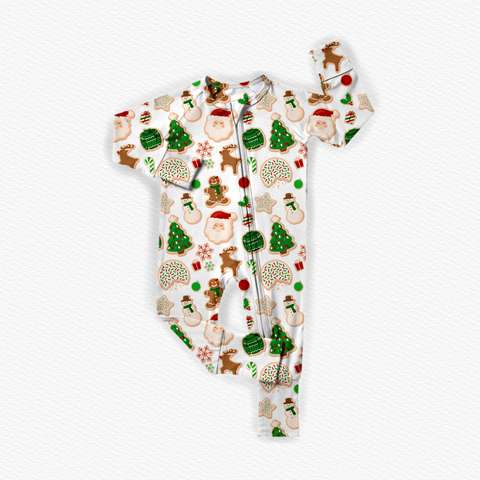

While discussions on GSM, density, and machinery are essential for technical understanding, design optimization for Christmas bamboo pajamas transforms them into market-ready products. The design focuses on ergonomics, ensuring flexibility and comfort, while also integrating holiday-inspired prints and color palettes such as snowy patterns, festive reds, and tree motifs.

The cutting-edge machinery includes laser-cutting and ultrasonic stitching systems. These technologies offer clean edges, seamless stitching, and reduced material wastage. Thus, each pajama set is not just a technical marvel but an artistic expression befitting the holiday season.

The Nexus of Sustainability and Performance

Christmas bamboo pajamas simultaneously exemplify sustainability and performance. By reducing reliance on conventional cotton sources, bamboo fiber decreases water usage during cultivation and leverages renewable resources. Additionally, industrial processes are evolving to curb emissions and energy consumption, making the manufacturing of seasonal pajamas increasingly green.

The technical design choices rooted in GSM optimization, fabric density calibration, and machinery advancement continue to elevate these garments. High standards of engineering not only position bamboo pajamas as consumer-friendly products but also as testaments to innovative manufacturing in today's textile industry.

Bamboo fabric is redefining the landscape of seasonal apparel, proving that innovation and sustainability can coexist seamlessly. The process of crafting Christmas bamboo pajamas involves a meticulous interplay of parameters like GSM and fabric density, complemented by the action of cutting-edge industrial machinery. From raw transformation to the embodiment of seasonal cheer, each step in manufacturing reflects technical precision and creative dedication. As businesses seek eco-conscious yet high-performance textiles to meet consumer demands, bamboo remains a frontrunner in the pursuit of progress within the apparel sector.