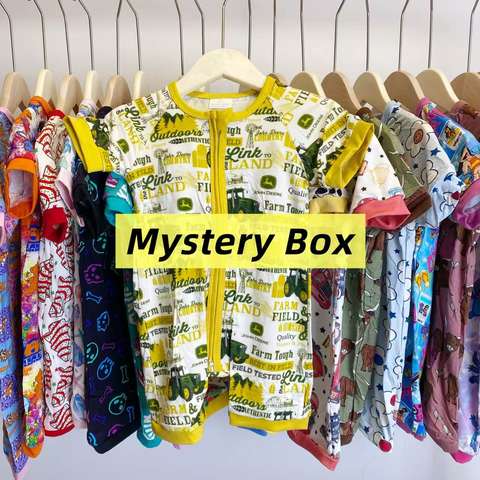

Cpsia Compliant Bamboo Pajamas Shell Print Oekotex 100 Wholesale

Understanding Bamboo Pajamas with Shell Print: Bridging Comfort and Technology

The apparel industry has seen a significant rise in eco-conscious trends, and bamboo fabric is at the forefront of this revolution. Bamboo pajamas with shell prints combine the sustainability of bamboo textiles with aesthetically pleasing designs. For businesses in the fashion or textile industries, the technical aspects like GSM (grams per square meter), fabric density, and the role of industrial machinery are key to producing the high-quality, eco-friendly garments the market demands. This article explores these facets in detail, with a focus on how technology shapes bamboo pajamas for modern consumers.

Bamboo Textiles: A Sustainable and Versatile Base

Bamboo is celebrated for being one of the most sustainable resources in the textile world. The process begins with mechanically or chemically converting bamboo pulp into viscose-like fibers, which are then spun into yarn. This material boasts several properties critical to comfort wear:

- Breathability: Bamboo fibers are naturally breathable, making them ideal for pajamas.

- Moisture-Wicking: The natural cellular structure of bamboo fabric efficiently wicks moisture, ensuring comfort.

- Softness: The textile is incredibly soft, comparable to luxury fabrics like silk or cashmere.

- Eco-Friendly Properties: Bamboo plants grow quickly without the need for pesticides or excessive water, reducing the environmental footprint.

Exploring GSM and Fabric Density

In the production of bamboo pajamas, selecting the right fabric weight and density is critical for achieving optimal comfort and durability. This is where GSM and fabric density come into play.

What Is GSM and Why Does It Matter?

GSM, or grams per square meter, refers to the weight of fabric per unit area. In essence, it indicates how heavy or light a fabric feels and directly impacts the functionality of the final garment.

- Low GSM (150-200): Lightweight bamboo fabric in this range is breathable and suitable for warmer climates or summer pajamas.

- Medium GSM (200-300): Fabrics in this range offer a balance of durability and comfort, ideal for year-round wear.

- High GSM (300+): Heavier bamboo materials provide better insulation, suited for winter-specific loungewear and pajamas.

For bamboo pajamas with shell prints, medium GSM is often the sweet spot. It ensures that the fabric is strong enough to bear intricate prints while still offering the lightweight, soft comfort desired in sleepwear.

Fabric Density and Its Role in Design

Fabric density complements GSM by looking at the tightness of the weave or knit. For bamboo textiles, the type of density used is dictated by the end product requirements:

- Tightly-Woven Fabric: Enhances durability, makes the surface smoother for printing, and reduces transparency.

- Loosely-Woven Fabric: Maximizes airflow and softness but is less suitable for patterns with intricate designs, like shell prints.

When creating bamboo pajamas with shell prints, it's important to select a moderately tight weave. This not only provides the perfect canvas for achieving intricate print designs but also complements the lightweight feel expected in sleepwear.

The Role of Industrial Machinery

High-quality bamboo garments require advanced industrial machinery for efficient and precise production. From fiber extraction to printing technologies, each step relies on cutting-edge engineering to create both functional and visually appealing products.

Fiber Processing Machinery

The initial stage of bamboo textile production involves converting raw bamboo plants into workable fibers. Machinery used during this phase includes:

- Mechanical Extraction Systems: These systems crush bamboo stalks, extracting natural fibers in an eco-friendly manner.

- Chemical Processing Equipment: Specialized machinery uses chemicals like sodium hydroxide to break down bamboo pulp into viscose rayon fibers.

The fibers are then cleaned, dried, and spun into yarn for further processing. The quality of these processes determines the softness, durability, and purity of the final fabric.

Textile Weaving and Sewing Machines

The next step in the lifecycle of bamboo pajamas is the fabrication process. During this stage:

| Fabric Type | Pima Cotton |

| Compliance | CPC Certified |

| Customization | Private Label |

| Lead Time | 34 Days |

- Looms: Industrial weaving looms create consistent and precise fabric layers with controlled weave density.

- Knitting Machines: Used for stretchable bamboo knit fabrics, ideal for loungewear and pajamas.

- Cutting and Sewing Automation: Automated fabric cutters and sewing machinery streamline the production process, ensuring consistency in garment dimensions and seam quality.

These machines allow manufacturers to scale up production while maintaining stringent quality requirements demanded by B2B clients.

Digital Textile Printing Systems

The final step that differentiates bamboo pajamas with shell prints from plain ones is the application of the design. Digital textile printing has become a game-changer in creating precise and visually appealing prints on delicate bamboo fabric.

- Eco-Friendly Printing Inks: Water-based inks used in bamboo fabric printing reduce harmful emissions while preserving the material’s softness.

- High-Resolution Printing Heads: These achieve intricate details, perfect for shell-themed patterns with subtle gradients and color variations.

- Heat-Bonding Technology: Fixes the print effectively without compromising the integrity or breathability of the fabric.

By leveraging these advanced printing techniques, businesses can create a wide array of shell print designs that align with various customer preferences.

Benefits for B2B Enterprises

For businesses operating in textile manufacturing or retail apparel, offering bamboo pajamas with shell prints can be a lucrative opportunity. The following benefits demonstrate why this product aligns with modern consumer expectations:

- Market Demand: With sustainability trending, consumers are seeking eco-friendly alternatives like bamboo fabric products.

- Brand Differentiation: Unique designs such as shell prints appeal to a niche market segment and can establish your company as an innovator in the field.

- Performance and Versatility: Bamboo’s natural properties make it ideal for everyday wear, a huge selling point for consumers.

By investing in efficient machinery and focusing on high-quality output, businesses can ensure they stay competitive in this growing market segment.

Bamboo pajamas with shell prints are much more than a fashion statement. They represent the intersection of sustainability, advanced fabric technology, and intricate design. For textile manufacturers and retailers, understanding the intricate interplay between fabric weight (GSM), density, and production methods is critical to developing successful products. , leveraging industrial machinery, from fiber extraction equipment to digital printing systems, ensures consistency, efficiency, and minimal environmental impact.

As global demand for eco-friendly apparel continues to rise, bamboo textiles offer a promising avenue for businesses seeking to innovate in the world of sleepwear and casual clothing. With the right technical expertise and tools, companies can transform sustainably-sourced bamboo into beautiful, comfortable products that support both profitability and environmental responsibility. Shell-patterned bamboo pajamas, in particular, hold a unique and attractive niche in this market—an opportunity no forward-thinking business should overlook.