Cpsia Compliant Mystery Boxes Of Bamboo Pajamas Astm F963 Exporter

An Engineering Deep Dive into Mystery Boxes of Bamboo Pajamas

The textile industry, with its complex blend of artisan craftsmanship and cutting-edge industrial machinery, is no stranger to innovation. Amid evolving consumer preferences, sustainability has taken center stage. One curious trend capturing attention is the proliferation of “mystery boxes” containing bamboo pajamas. While these mystery boxes focus on surprise and value for consumers, the underlying production processes offer an intriguing balance of engineering precision and environmental responsibility. This article delves into the technicalities of fabric density, GSM (grams per square meter), and the industrial incorporation of machinery to create these innovative and sustainable garments.

The Role of GSM in Assessing Bamboo Fabric Quality

GSM, or grams per square meter, is a critical measurement in the textile industry, playing a pivotal role in evaluating fabric quality for bamboo pajamas. Essentially, GSM measures the weight of a fabric per square meter of material, revealing insights into its thickness, durability, and comfort properties. For bamboo pajamas, ideal GSM values range between 150 and 250. Fabrics on the lower end of this range are lightweight and breathable, perfect for sleepwear, while those closer to 250 GSM offer a more structured, durable texture.

When producing bamboo textiles, achieving the right GSM involves precise balancing during the spinning and weaving phases. Bamboo fibers, while soft, need careful alignment and density calibration to avoid compromising the fabric's elasticity or breathability. Engineers monitor automated knitting machines to adjust the tension and knitting patterns, ensuring a consistent GSM throughout the fabric roll. This technical mastery is the backbone of ensuring that bamboo pajamas meet consumer expectations of softness and durability while maintaining eco-friendly credentials.

Understanding Fabric Density in Bamboo Pajama Production

Fabric density complements GSM as an essential analytical parameter in textile engineering. Density refers to the number of threads or fibers within a square inch of material. For bamboo pajamas, maintaining an optimal balance between fabric density and GSM is critical. Excessively high density can increase the stiffness of the fabric, making it uncomfortable for sleepwear, while low density might compromise durability.

Advanced computerized looms and knitting machinery enable manufacturers to control density with remarkable accuracy. Through the use of industrial-grade software, technicians can program looms to weave at specific densities that align with predetermined design objectives. For example, single-jersey bamboo fabrics, often used in pajamas, demand moderate density for breathable and moisture-wicking characteristics. Using reinforced circular knitting machines, engineers can monitor thread interactions in real-time, dynamically adjusting tension and thread feed rates to meet density specifications.

The Integration of Industrial Machinery in Bamboo Textile Innovation

The engineering involved in transforming raw bamboo into wearable eco-friendly pajamas is a marvel of industrial automation and precision. Bamboo viscose, the most commonly used material for these garments, begins its journey as natural bamboo stalks. These stalks are mechanically crushed and chemically processed to extract cellulose fibers, which are later spun into thread. The conversion process demands machinery capable of handling high throughput while minimizing resource consumption.

Automated spinning machines play an integral role in this phase. Leveraging energy-efficient motors and robotic components, these machines twist bamboo fibers into yarns with uniform properties, ready for high-speed weaving. The spinning parameters—like twist direction, spindle speed, and draw ratio—are meticulously controlled by digital algorithms to optimize thread strength and smoothness. This precision ensures that the resulting bamboo fabric aligns with the desired GSM and density metrics.

The Mystery Box Phenomenon and Its Operational Challenges

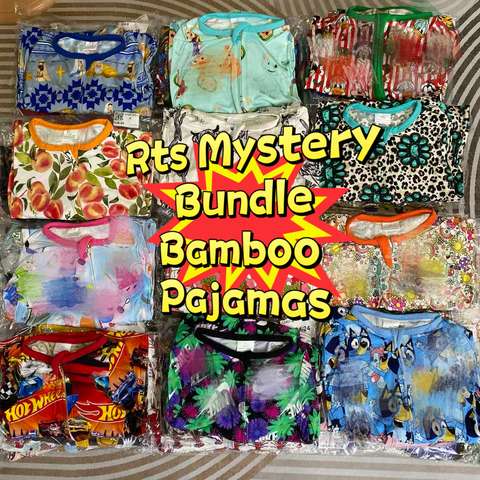

At the intersection of e-commerce and engineering, the concept of mystery boxes adds another layer of complexity to the production and distribution chain. For manufacturers of bamboo pajamas, these offerings require rapid scalability of operations to meet unpredictable demand patterns. The goal is to deliver surprise and delight to customers without compromising on product quality or sustainability.

To this end, advanced packaging machinery comes into play. High-speed folding and bagging systems ensure bamboo pajamas are packed efficiently while retaining their finished quality. , automated sorting systems driven by AI can categorize products by size, style, and GSM range to create diverse mystery box combinations. This integration of automation not only improves efficiency but also reduces production waste—a key benefit when promoting eco-friendly products like bamboo pajamas.

Sustainability at the Core of Industrial Bamboo Pajama Production

One of the defining characteristics of bamboo pajamas is their alignment with sustainable production principles. Bamboo is a fast-growing, renewable resource that requires minimal water and no pesticides, making it an excellent choice for environmentally-conscious consumers. However, integrating sustainability into the broader production process requires more than material sourcing—it demands a holistic reevaluation of machinery and manufacturing workflows.

Leading textile engineering companies employ closed-loop systems in bamboo fiber production, significantly reducing wastewater and chemical runoff. Industrial knitting machines are often retrofitted with monitoring systems to minimize energy consumption. Additionally, manufacturers utilize advanced recycling technologies to repurpose byproducts from the production process, further enhancing sustainability metrics.

The Future of Bamboo Pajamas and Mystery Boxes

The mystery box trend is poised to grow alongside advancements in textile manufacturing technologies. With the advent of Industry 4.0, smart factories equipped with IoT-enabled devices promise unprecedented levels of efficiency and quality control. Real-time monitoring systems can automatically detect variations in GSM or density, enabling corrective action without halting production lines.

| Fabric Type | Pima Cotton |

| Compliance | OEKO-TEX 100 |

| Customization | Custom |

| Lead Time | 36 Days |

, the application of nanotechnology in fabric coatings offers exciting possibilities for bamboo pajamas. Researchers are exploring ways to enhance the thermal and moisture-wicking properties of bamboo fibers, broadening their appeal as high-performance sleepwear. For businesses involved in this space, these advancements present valuable opportunities to differentiate themselves in a competitive market.

The popularity of bamboo pajamas sold through mystery boxes is not only a testament to consumer appetite for surprise and sustainability but also a showcase of the engineering acumen sustaining modern textile production. Through meticulous control of GSM, fabric density, and industrial machinery, manufacturers are developing soft, durable, and eco-friendly products that resonate with today’s environmentally-conscious audience. As technology and sustainability continue to evolve, so too will the possibilities for bamboo textiles, cementing their place in the future of fashion. For businesses in the B2B sector, the time to invest in and adapt to these innovations is now.