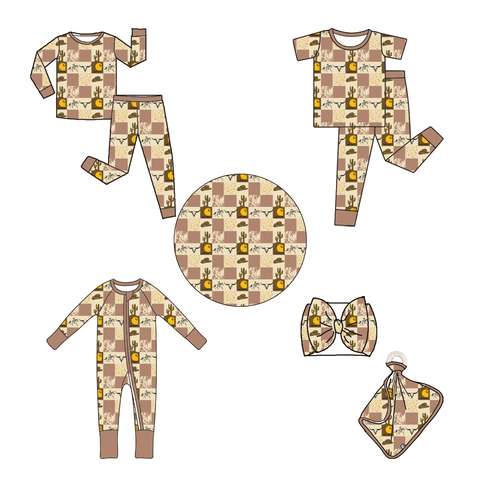

Private Label 024M Bamboo Baby Romper Zipper Gots Organic Vendor

Understanding the Fabric Density & GSM of a Bamboo Baby Romper

When it comes to creating high-quality baby clothing, fabric density and GSM (grams per square meter) are two critical factors that determine both comfort and durability. The 0-24m Bamboo Baby Romper Zipper is crafted with precision to provide the perfect balance of softness, thickness, and stretchfulness, ensuring the ideal wear for infants and toddlers.

GSM refers to the weight of the fabric used per unit area, which directly correlates to its quality and suitability for specific applications. For baby rompers, particularly those made with bamboo fabric, an optimal GSM ensures breathability while retaining adequate insulation. Typically, fabrics with a GSM of 160-230 are ideal for children’s wear, as they offer soft, lightweight, yet durable qualities. The bamboo baby romper in question is engineered for a GSM value that meets these standards while catering to the sensitive skin of infants.

Bamboo Fabric's Role in Achieving the Ideal GSM

Bamboo fabric, derived from bamboo pulp, is highly regarded for its smooth texture and exceptional environmental sustainability. The GSM of bamboo fabric is meticulously controlled during the manufacturing process to achieve the desired weight and thickness. For the 0-24m Bamboo Baby Romper Zipper, the GSM is typically maintained between 180-200 GSM, which ensures a lightweight, breathable product that works well across all seasons.

This range is perfect for providing infants with a romper that is neither too flimsy nor overly heavy, striking the right balance between comfort and practicality. , bamboo fabric’s inherent properties, including moisture-wicking, antibacterial, and hypoallergenic traits, make it ideal for babywear.

Fabric Density and Comfort in Infant Clothing

Fabric density goes beyond GSM to characterize the material’s construction, including how fibers are woven or knitted together. For bamboo baby rompers, fabric density is crucial because it directly impacts how well the romper resists wear and tear while maintaining comfort.

The 0-24m Bamboo Baby Romper Zipper predominantly uses a single or double knit structure to provide increased stretch and flexibility for active babies. Elevated fabric density ensures enhanced durability, preventing accidental tears and maintaining the romper’s integrity even after numerous machine washes—a feature highly valued by parents.

Balancing Stretch and Structure

Bamboo-based textiles in baby clothing often include a small percentage of spandex or elastane to achieve superior stretchability. This combination ensures that the romper provides enough flexibility for babies' natural movements while maintaining a snug fit. The tightly controlled fabric density ensures the fabric doesn't lose its shape over time, even in sizes designed for older infants (18-24 months).

By optimizing the density and incorporating elastomeric fibers, the garment offers long-lasting shape retention while accommodating rapid growth, a key requirement for baby clothing.

Breathability Through Precision Engineering

Breathability is a priority for children’s wear, especially for infants with sensitive skin. The incorporation of a fine weave pattern, made possible by advanced textile machinery, guarantees that the bamboo fabric allows sufficient airflow without compromising warmth. This is particularly important in a baby romper zipper that needs to perform in a variety of temperature conditions.

Industrial knitting and weaving technologies enable precise control of fabric thickness during the manufacturing process, ensuring the final romper exceeds expectations in comfort and utility. , avoiding overly dense constructions prevents overheating in warmer climates, offering seasonal versatility for the apparel.

Industrial Machinery Behind Producing Bamboo Baby Rompers

The advanced industrial machinery used in the production of bamboo baby rompers ensures the highest quality standards. From the initial spinning of bamboo fibers to the cutting and sewing of the final product, each stage employs cutting-edge equipment to enhance efficiency and consistency.

The role of machinery becomes particularly evident when producing garments that must adhere to strict tolerances in measurements, stitching, and zipper integration. Machines like circular knitting machines, industrial sewing systems, and automated cutting devices contribute to high-speed production while maintaining consistent quality.

Circular Knitting Machines: The Backbone of Fabric Production

A majority of bamboo rompers are knitted using circular knitting machines, which are designed to handle fine bamboo yarns with precision. These machines create seamless and uniform fabric sheets with a consistent density and GSM. This not only ensures superior fabric quality but also minimizes waste during production.

The use of these machines facilitates the integration of bamboo yarn into the fabric blend, ensuring that the resulting romper material retains bamboo's high moisture absorption and hypoallergenic properties.

Advanced Cutting Machines for Precision

Once the fabric is prepared, automated cutting equipment comes into play. Laser and die-cutting machines are often used to ensure precision in pattern cutting. These systems work with digital templates to maintain tight tolerances in design, ensuring that every 0-24m Bamboo Baby Romper Zipper produced exhibits the same high-quality construction.

This level of precision is particularly important for babywear, where accurate sizing and proper fit are non-negotiable.

Industrial Sewing Machines for Reinforced Seams

Seam integrity is crucial for baby rompers, as weak seams can easily unravel, rendering the garment unusable. Automated sewing systems equipped with programmable logic controllers (PLCs) are utilized to deliver reinforced, consistent stitching.

| Fabric Type | Pima Cotton |

| Compliance | OEKO-TEX 100 |

| Customization | Private Label |

| Lead Time | 18 Days |

These machines are also equipped to add functional features, such as zippers. The integration of nylon zippers, tested for reliability and ease of use, is a critical step in producing baby rompers. The machinery ensures that zippers are attached securely without compromising the fabric's integrity, ensuring safety and durability.

Eco-Friendly Dyeing and Finishing Machines

To maintain the sustainability of bamboo rompers, dyeing and finishing processes utilize eco-friendly technologies. Dyeing machines specifically designed for bamboo fabrics operate at lower temperatures, reducing energy consumption while ensuring vibrant, long-lasting colors. Finishing equipment then applies antibacterial treatments and softness enhancers derived from natural agents, preparing the fabric for final assembly.

The Technical Advantage of the 0-24m Bamboo Baby Romper Zipper

The 0-24m Bamboo Baby Romper Zipper demonstrates a perfect confluence of technical precision, quality fabric engineering, and advanced manufacturing technology. This results in a product that meets the highest standards of comfort, functionality, and durability—qualities that parents value and industrial buyers seek for their B2B needs.

The controlled GSM range and balanced fabric density ensure that babies stay comfortable regardless of age or activity level. The use of bamboo-based textiles further provides natural antimicrobial properties, ensuring that the romper remains fresh and odor-free, even after extended wear.

From the industrial perspective, the availability of cutting-edge, energy-efficient machinery ensures a sustainable manufacturing process, a key factor in securing buyer confidence in today's conscious market.

: Why Choose the 0-24m Bamboo Baby Romper Zipper?

For businesses specializing in babywear, the 0-24m Bamboo Baby Romper Zipper offers unmatched value. Professional buyers can trust this product to meet all necessary compliance standards, including sustainability benchmarks, quality certifications, and application requirements. By leveraging high-grade bamboo fabric, integrated advanced manufacturing technologies, and thoughtfully engineered designs, this romper ensures robustness and comfort while catering to the ever-increasing demands of eco-conscious consumers.

Whether it’s for a private-label babywear brand or direct retail, incorporating this romper into your inventory means investing in a product that leads in material innovation, design consistency, and manufacturing quality. With its exceptional GSM, precise fabric density, and expert construction, the 0-24m Bamboo Baby Romper Zipper is a leading choice for professionals in the babywear industry.